WD or WD45 2-speed range box

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Pulling Forum

Forum Description: Forum dedicated to Tractor and Garden Pulling

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=119306

Printed Date: 31 Jan 2026 at 3:46pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD or WD45 2-speed range box

Posted By: DrAllis

Subject: WD or WD45 2-speed range box

Date Posted: 21 Feb 2016 at 6:47pm

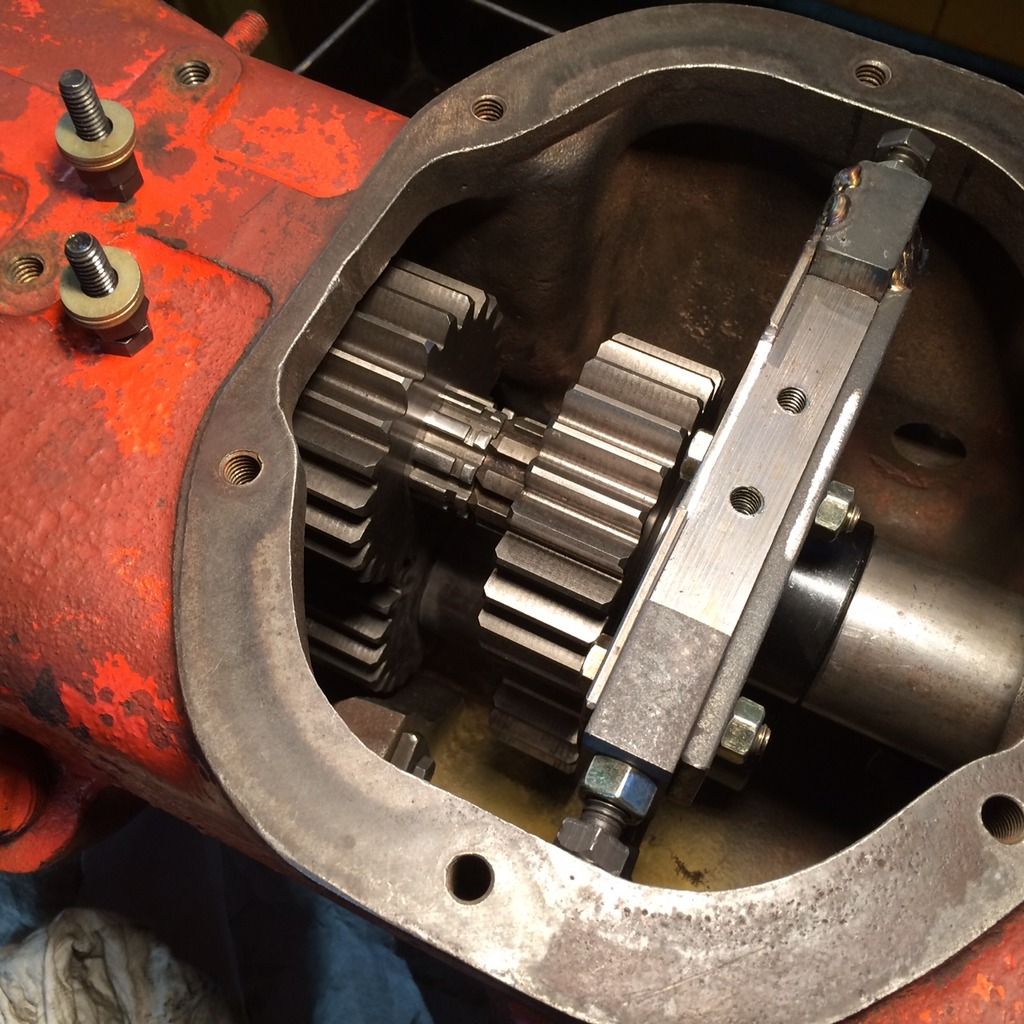

| Hopefully the photo will follow this thread. This was my Winter project, a 2-speed range transmission located inside where the hand clutch and PTO gears used to be located. I set this one up as a 15% under-drive. This places low 3rd and low 2nd half-way in-between normal direct drive speeds. Essentially, it makes the tractor 8-speeds, four direct-drive and four under-drive. It could be made into an over-drive if desired. Totally enclosed and nothing exposed. I'd be interested in making more if there's a market. While still a prototype, this one has been down the track four times already with no issues whatsoever. While not cheap to build, there's no more compromising on speed selections with this accessory. |

Replies:

Posted By: coggonobrien

Date Posted: 21 Feb 2016 at 6:50pm

http://s161.photobucket.com/user/coggonobrien/media/Dr%20Allis%20Skunkworks/IMG_0241_zpsq6boh0zg.jpg.html" rel="nofollow">

|

Posted By: Charlie175

Date Posted: 21 Feb 2016 at 7:20pm

|

That's pretty cool, how does it work? ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: DrAllis

Date Posted: 21 Feb 2016 at 7:27pm

| There's a blocker sleeve that goes between the two top gears. Right now it's in under-drive. Remove the blocker sleeve and slide the top rear gear forward and it's in direct-drive. Reinstall the blocker sleeve and cover it up. |

Posted By: Fields

Date Posted: 21 Feb 2016 at 10:06pm

| Interesting. |

Posted By: Charlie175

Date Posted: 22 Feb 2016 at 5:35am

|

I have started to see more WC Transmission adaptions pop up, but this would be even better since it is not visual. ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: DrAllis

Date Posted: 22 Feb 2016 at 6:04am

| Exactly, and the ratios could be chosen to almost whatever you want. |

Posted By: Larry(OH)

Date Posted: 22 Feb 2016 at 7:01am

|

I like it!! ------------- '40 WC puller, '65 770 Ollie *ALLIS EXPRESS contact* I can explain it to you, BUT I cannot understand it for you!! |

Posted By: CTuckerNWIL

Date Posted: 22 Feb 2016 at 9:21am

Now you just need to add a shifter groove to that top gear, a detent system to do away with the sleeve and figure out a shifting fork that is "out of the way"

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: DrAllis

Date Posted: 22 Feb 2016 at 9:38am

| That was my original plan, but was so excited to get it up and working, I ditched that idea. Most of the time, I'll be in Low 2nd anyway, so changing it often won't be needed in my case. |

Posted By: O.P.S. Heads

Date Posted: 22 Feb 2016 at 9:59am

| The way I see it, you've designed a transmission system that will work in a wide range of engines from 50 HP on up. 1st gear with the gear box in under drive should still work with a pretty much stock engine with 38 inch tires. Big power engines have a gear between every gear. Pretty neat. |

Posted By: Larry(OH)

Date Posted: 22 Feb 2016 at 10:54am

|

So the big question....cost$$ ------------- '40 WC puller, '65 770 Ollie *ALLIS EXPRESS contact* I can explain it to you, BUT I cannot understand it for you!! |

Posted By: DrAllis

Date Posted: 22 Feb 2016 at 11:31am

| Almost a semi-load of corn installed and turn-key in your existing torque housing. That's one of the issues....I have to have a torque housing with the clutch shaft AND the transmissions input shaft. |

Posted By: CAL(KS)

Date Posted: 22 Feb 2016 at 12:04pm

its awful dry here we cant grow much dryland corn, would you take a load of sorghum LOL sadly about the same price now  i would imagine the gears in batches would bring the cost down.. but youd have to sit on them... i would imagine the gears in batches would bring the cost down.. but youd have to sit on them...do the bolts sitting in the pic go through a heavy plate on top?>

------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: DrAllis

Date Posted: 22 Feb 2016 at 1:03pm

| The picture wasn't quite the finished product, and yes, there is a plate that bolts to the top to keep the rear bearing support from moving around. I'll probably got to Gr8 studs with flange nuts instead of just bolts. |

Posted By: DrAllis

Date Posted: 22 Feb 2016 at 6:22pm

| Gears custom made in batches, usually means 25 or 50 or 100, and then there's the matter of what exact gear ratio one might want. That's why these things are expensive.....very low demand. |

Posted By: MACK

Date Posted: 13 Mar 2016 at 8:28pm

| Could you use splined hubs like my gearboxes use, then use Profab or SCS gears to lower the price of gears? Or are your shaft centers too close togather? MACK |

Posted By: DrAllis

Date Posted: 14 Mar 2016 at 4:12pm

| Profab gears too far apart...not enough room in the housing. |

Posted By: allischalmerguy

Date Posted: 14 Mar 2016 at 10:59pm

|

DrAllis and company... That is pretty neat thinking there! Wow! Will you be at Sigourney on Saturday to test it there? Pastor Mike ------------- It is great being a disciple of Jesus! 1950 WD, 1957 D17...retired in Iowa, |

Posted By: SteveM C/IL

Date Posted: 28 Mar 2016 at 7:35pm

| Certainly a simple and clean concept.I like it! |

Posted By: JoshL

Date Posted: 04 Jul 2016 at 1:40pm

|

Dr Allis, I would be interested in something like that. How much would the cost be of the exact type? 15 percent underdrive. |

Posted By: CTuckerNWIL

Date Posted: 04 Jul 2016 at 3:41pm

|

Almost a semi-load of corn installed and turn-key in your existing torque housing. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: DrAllis

Date Posted: 28 May 2017 at 4:12pm

| Just an update on this two-speed transmission. All of 2016 season and thus far in 2017, there have been 29 hooks made with this tractor. 27 of them were in 15% under-drive and 3 were in direct drive. Thus far, no issues whatsoever. The 15% under works out quite well in 3.5 to 4.0 MPH classes in second gear.. |

Posted By: One Sick Puppy

Date Posted: 13 Mar 2020 at 2:24pm

| Dr. Allis, I take it you removed the oil clutch and hydraulic pump to accomplish this? Did you have the gears cut for this project, or did you find something usable with a proper shaft/countershaft centerline? |

Posted By: DrAllis

Date Posted: 13 Mar 2020 at 2:56pm

| Hydraulic pump, PTO gears and hand clutch removed to make room. Gears and countershaft custom made for the project. |

Posted By: One Sick Puppy

Date Posted: 13 Mar 2020 at 3:38pm

| Dr. Allis, are you making parts for these as Kit? I'd be interested in purchasing the appropriate gearing. I'm going to start the process of replacing my 226 cu. in. engine with an Allis Chalmers 433T. That engine has a significantly higher "high idle", so additional lower gear ratios would be to my advantage. |

Posted By: DrAllis

Date Posted: 13 Mar 2020 at 8:14pm

| Not interested in making another one. I've sold the tractor that had that 2-speed in it. If you install a D-17 ring and pinion or use a WD45 diesel rear end, they are geared 15% slower. That 433-T engine peaks torque at 1700 RPM and a WD45 diesel ran 1900 RPM high idle. I think you'd like the 15% reduction. |