ac hd 6 b sprocket and nut

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=112694

Printed Date: 10 Feb 2026 at 8:49am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: ac hd 6 b sprocket and nut

Posted By: dragboat1

Subject: ac hd 6 b sprocket and nut

Date Posted: 30 Sep 2015 at 10:39am

| does the sprocket nut have a wedge taper that fits in the sprocket mine nut only contacts the sprocket with the edge of the nut flats i dont think this is correct it does not look wright |

Replies:

Posted By: CAL(KS)

Date Posted: 30 Sep 2015 at 1:11pm

|

hd6b is same design as my HD16. double reduction finals just smaller. the sprocket is splined to fit taper spline of sprocket shaft. should be a lock ring holding the nut from turning, back side of nut fits directly to sprocket. that nut is 2000 some ft/lbs torque on my 16. probably correct nut, maybe just how your looking at it. may be a protrusion on nut to fit counter bore of outside of sprocket, I cant remember, but from the parts book it appears to have something similliar http://minnpar.com/manuals.asp" rel="nofollow - minnpar manuals you can view the breakdown directly http://www.minnpar.com/partbooks/Allis%20Chalmers%20Construction%20%26%20Fiat%20Allis/Dozers/HD-6%20%20PRIOR%20TO%20SN%2013322.PDF" rel="nofollow - here page 144 of pdf ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: Coke-in-MN

Date Posted: 30 Sep 2015 at 3:55pm

|

was trying to remember also but believe the nut is flat and there is a locking fixture that holds nut once tight I used a 10 ft length of pipe fit over handle of wrench I used to grip nut . then applied my weight to end of pipe for final torque on nut - figured about 2,000 ft lbs torque at end of pipe ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dragboat1

Date Posted: 30 Sep 2015 at 4:08pm

|

|

Posted By: CAL(KS)

Date Posted: 30 Sep 2015 at 4:25pm

|

page 164 shows the truck frame parts. if the pin and bushings are worn at thepivot that would add stress to the outer bearing area of the shaft by allowing the truck frame to move. on my 16 there is a tube from the diff housing allowing oil to flow down and lubricate that pin. if it leaks its probably out of spec. luckily I have not had any trouble in that area. the outboard bearing needs to be shimmed properly and its possible your truck frame is bent adding stress at the outboard bearing. consult your service manual about the adjustments and tolerances allowed on those parts ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: Dozer

Date Posted: 30 Sep 2015 at 4:42pm

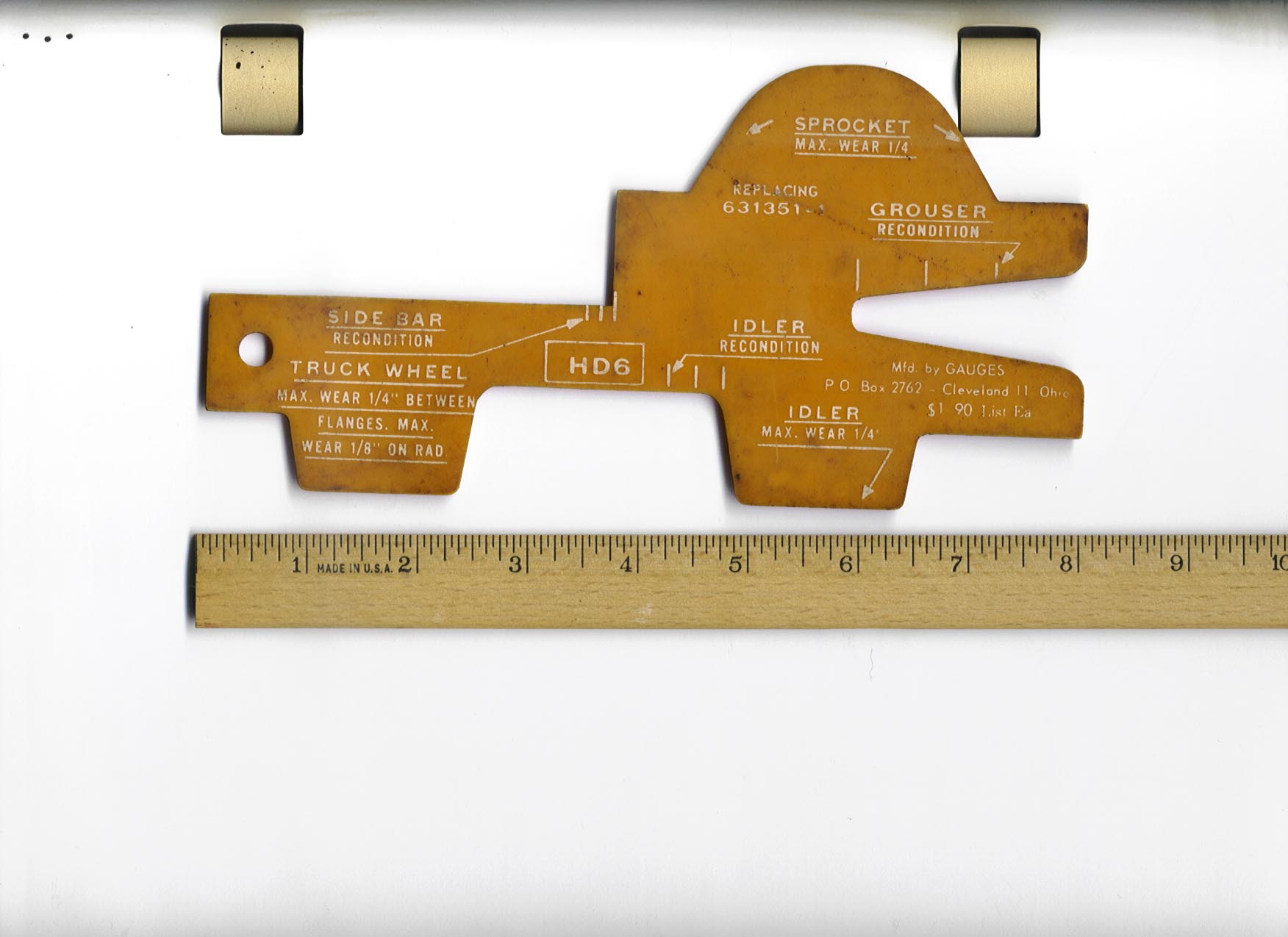

Sprocket nut and locking ring for HD6G. There are 2 hex sizes depending on axle spline. |

Posted By: Coke-in-MN

Date Posted: 01 Oct 2015 at 9:26am

|

Had the problem with the HD5B I had , the truck frame pivot inder back of tractor was worn and one bolt hole would not hold bolt tight allowing truck frame to move - Welded it up and ground area to hold pin tight - replaced axle and outboard bearing - ran machine couple years and no problems when sold . I do have a spare axle in my pile of spare parts yet I will sell . 2 splines were used a small spline and large spline - large more like what is used on clutch disc only larger and tapered.

------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dragboat1

Date Posted: 01 Oct 2015 at 4:45pm

|

thanks every one for the input. mr coke was the place where pivot pin hooks under dozer worn out where caps fit .this is my problem i was thinking of welding it up and grinding it out to make pin fit .just dont know how to aline the pin. dont know wonder if close is good . |

Posted By: Coke-in-MN

Date Posted: 01 Oct 2015 at 5:23pm

|

the pin fits into saddle and lower cap on each end keeps it from moving - if you have a lot of slop there then might look at shimming the pin or replacing it as it sounds like your pin is worn also . might drop the other side and see what clearance is there also - with the 5A, 5B they used a equalizer spring so all the truck frame force is onto the bearing / axle and on those 2 mounting points on rear case . On the 5G and 5E they used a rigid cross member between truck frames and tractor frame - thus helped support the loader frame and oil tanks / lift towers for the loader . When I first got the machine and the truck frame was walking out on the one side I ran a cable across between truck frames to finish a job before i tore into machine . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dragboat1

Date Posted: 01 Oct 2015 at 6:09pm

| the saddel and cap is worn .my friend put nw pin and bushing in truck but its worn at the cap and saddle .i just dont want the owner to have any problems. i have rebuilt about 7 or 8 tractor engines for him just never worked on the dozer. he has 3 dozers . hes all AC .has b.c ,wd,wd45, 190. 2.d19.d17, 7060.7080.wc. knot sure what else .and i rebuilt the engine in the hd6b. but thats enough hes a good man i just want to do it wright as i can. |