| Author |

Topic Search Topic Search  Topic Options Topic Options

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: HD5G track idler wheel repairs? Topic: HD5G track idler wheel repairs?

Posted: 28 Mar 2014 at 7:04am |

Hi, I have for a long time now had trouble with throwing my left track whenever I would back up and turn. The grease tensioners would not hold track tension. Maybe seals are dried out and bad? 60 years is a long time for rubber to hold together. Anyway Ive always been able to beat the track back on before with prybars and a sledge hammer. This time I finally said "enough". I decided to remove the track from the idle wheel and see what I may be able to repair. I found the slides on the frame to the idle wheel bearings rusted frozen. Strangely at a slant pointing inwards toward the frame. So this may have been part of the problem along with the loose tensioner. Also found the idle wheel itself worn on the middle of the wheel. Where the center raised lip is. its not very square like a good one should be. Instead its worn almost thru on the inside edge. So my question is this: is it even possible to weld up the area and grind smooth to build up to a better shape? I really dont want to spend many hundreds of dollars on spare idle wheels off of ebay if I could fix what Ive got. It appears to be steel. But is it cast or some kind of forging? Will I need nickle rod or is normal rod ok for this? What are your thoughts?  |

|

|

Sponsored Links

|

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2014 at 7:20am Posted: 28 Mar 2014 at 7:20am |

|

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2014 at 7:27am Posted: 28 Mar 2014 at 7:27am |

More pics: And this is what I think the idle wheel center should look like istead of what Ive got.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2014 at 1:21pm Posted: 28 Mar 2014 at 1:21pm |

the welding up by hand I have tried - cant get a smooth bead - they are welded in shop by submerged are -wire feed - to get a even weld and good profile. That slide can be repaired or new material used to replace - but remember there are shims in there also to get wheel positioned. The outside guides that run on those slide also will show wear , I reversed mine to allow a new surface to come into play. Check also for bent axle on the wheel as well as bearings

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2014 at 1:23pm Posted: 28 Mar 2014 at 1:23pm |

|

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2014 at 2:41pm Posted: 28 Mar 2014 at 2:41pm |

|

You can weld them up with normal 7018 rod. Like Coke said, it wont be a smooth polished surface, but laying on 1/4 inch of weld is better than having the sloppy chain bounce around. You can lay the wheel on its side and just weld around and around. Just remember to ground the welder to a tab welded to the wheel. Do not let it ground the thru the shaft/ bearings. If your not real good with a welder, some grinding to cleanup afterwards might help.

|

|

Like them all, but love the "B"s.

|

|

Andrew_D

Silver Level

Joined: 28 May 2013

Location: Newdale,MB,Can

Points: 148

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2014 at 4:13pm Posted: 28 Mar 2014 at 4:13pm |

|

Do you have access to a lathe large enough to spin the idler? I'd turn it down to get fresh (and hopefully non-work hardened) metal. Then weld it up and machine it back down again.

Not sure if it is an effect of the photo, but that track frame looks like it is sprung to me. Might be a good time to do a complete tear down of that Left side track frame. As Coke said, since everything is apart, now is the time to check for axle straightness, bearing play, seals, rollers, etc.

Andrew

Edited by Andrew_D - 28 Mar 2014 at 4:17pm

|

|

ac_sd

Silver Level

Joined: 23 Apr 2011

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 12:29am Posted: 29 Mar 2014 at 12:29am |

|

I agree with Andrew_D in His approach. Your idler is worn out as are the "guide plates" on the top of the track frame that it moves on. All of this will contribute to Your problems. I'd check around and get a replacement idler which should not be all that costly. I have several good ones, but I'm in San Diego. John Parks at General Gear has a lot of AC used parts and is a really good source and good to deal with.

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 7:27am Posted: 29 Mar 2014 at 7:27am |

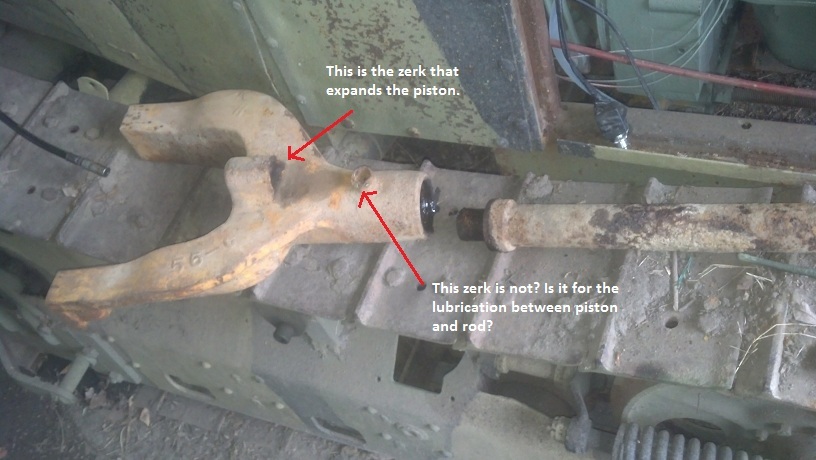

Thanks for the advice everyone. Im not sure how I will proceed yet, but It is good to know that I can weld it if I choose that path. The photo of the track frame sprung is a distortion of the photo. It actually straight. I will be replacing the sliding shim steel that is rusted and broken. The idler wheel and axle spin true on the bearings. Not bent as I can tell. Suprisingly, the bearings are smooth and tight. Feels like they still have lube as they turn! very happy about that. Im happy that I can weld this wheel as I had been told that it wast cast and near impossible. But replacement is looking unlikely in the short term as im low on funds. But I will look for a pair of better wheels in the future. On a side note, I had always had my tracks tensioned loose as I could not get the grease tensioner pistions to move. I cleaned that all up and found I had been putting grease in the wrong zerk to get it to move. I was able to clean and get grease into the other zerk fitting and watched the piston expand. So im very hopeful now about being able to put proper tension on track once I get it back together. Again thanks for ideas.

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 537

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 7:33am Posted: 29 Mar 2014 at 7:33am |

|

I would set it up on it's side and weld it with a wire feed welder. have someone turn it slowly to keep the bead as uniform as possible. will take some good communication for sure. the cause is the wear plates on the bottom (that are stuck to the idler) and the sides (which show wear on the other side). they need to be kept up after and more shims installed from time to time. also, by the looks of the roller shown, the tracks are wearing on the outside and not as much on the inside. this makes for a ramp for the track to start to come off if loose. I have a set on a dozer that liked to come off and I found the rear outboard bearing bad allowing the track frame to move and throw the track if I was not careful. I did not find it in time and had to replace the axle. make sure you check the outboard bearing and the bushing on the track frame arm before you put it back together. the pad that the center pivot rides on the track frame can get worn and want to push the track frame out also. if the adjuster is not leaking grease, then it will hold the track in correct tension. you are lucky to have them. mine has the threaded kind that are always frozen. good luck.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 7:59am Posted: 29 Mar 2014 at 7:59am |

Some more pics: Cleaning off rust from sliding surfaces of idle wheel bearing blocks. Wire brush and file work. Have a broken bolt to remove too. I was able to compress the tensioner by removing the zerk fitting and putting a winch strap around it to squeeze the old grease out of it till fully compressed. Then put fitting back in and its ready for installation. Gained about an inch compressed. Should make putting track back on a bit easier. Test fitting back on track frame. It sits deeper inside since compressed. Was gonna reuse slide shims, but now will make new ones.

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 9:23am Posted: 29 Mar 2014 at 9:23am |

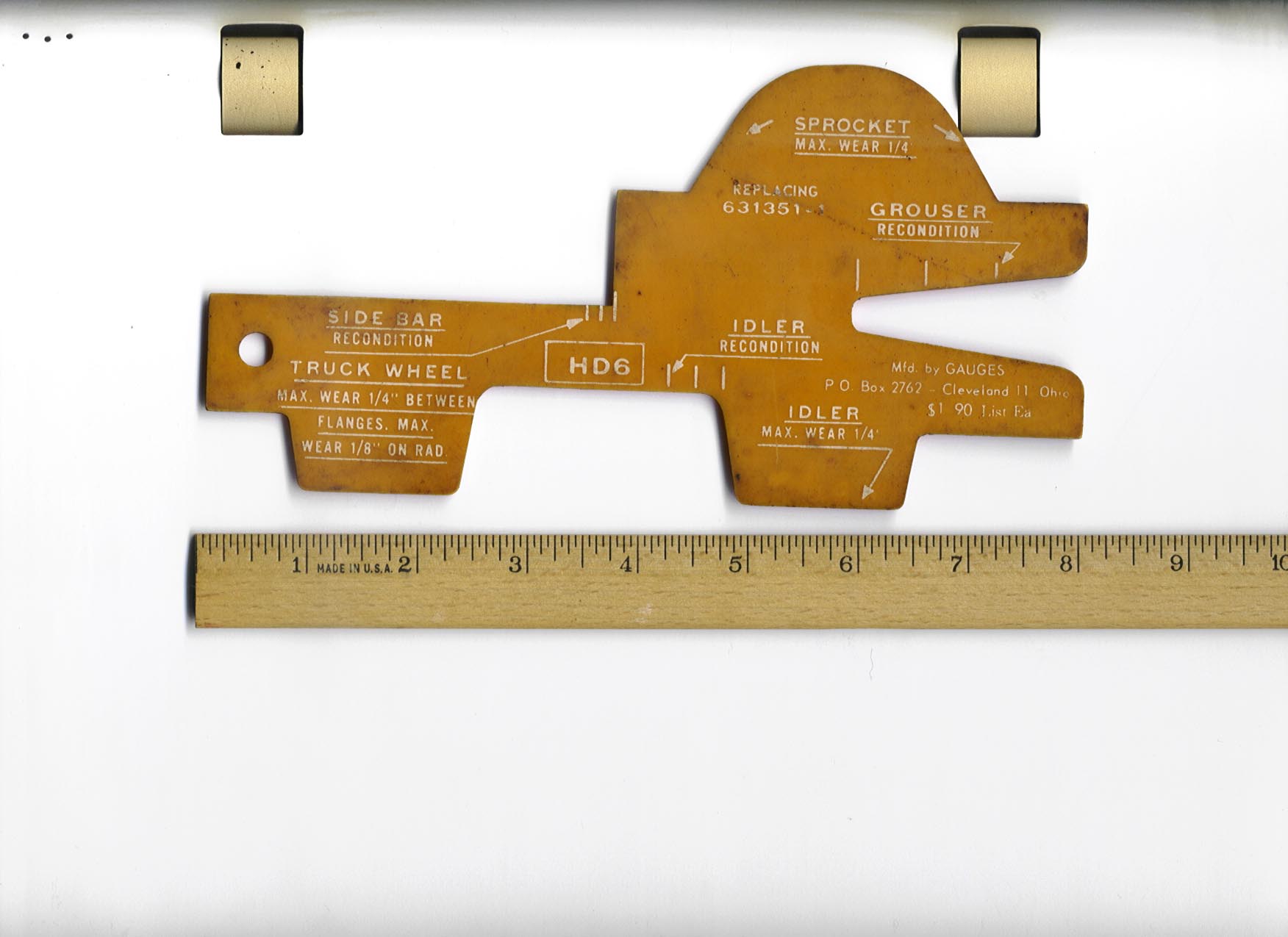

I think my grease trac adjusters are aftermarket. They aren't in the factory parts manual. Henderson Manufacturing Company Called HYDRA-JUSTERS

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34394

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 11:15am Posted: 29 Mar 2014 at 11:15am |

|

Keep the pictures coming, it is interesting about the hydra-justers.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

Andrew_D

Silver Level

Joined: 28 May 2013

Location: Newdale,MB,Can

Points: 148

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 11:33am Posted: 29 Mar 2014 at 11:33am |

rwhendrix wrote: rwhendrix wrote:

I think my grease trac adjusters are aftermarket. They aren't in the factory parts manual. Henderson Manufacturing Company Called HYDRA-JUSTERS |

I'll have to keep these in mind if I ever have a spring go bad on my HD11. I don't know what they cost compared to new spring parts, but worth looking into! Andrew

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 12:43pm Posted: 29 Mar 2014 at 12:43pm |

Don't over tighten the track when adjusting - to tight will cause many problems also . figured they might be aftermarket on the grease type adjusters - as my 1955 HD5G has the threaded rod for adjusting . As the adjuster is same on HD6 a lot of machines out there for after market parts supplier to sell to .

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

ac_sd

Silver Level

Joined: 23 Apr 2011

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2014 at 4:43pm Posted: 29 Mar 2014 at 4:43pm |

|

Your track adjusters are the later HD-6 Hydraulic track adjusters that some one has replaced the original with. That other zerk fitting is to release pressure to retract the adjuster. They are good.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar 2014 at 11:26am Posted: 30 Mar 2014 at 11:26am |

|

Have a metal shop make rings the same diameter as the idler from 1/2 dia. CRS. Weld the ring to the idler as a base for the hard face welding. Given that the CRS is soft it will save a lot of welding. It is easy to make a mess when a large number of hand welded passes are needed. You have a large amount of material that is worn off your idler. Welding rod is expensive too.

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 6:53am Posted: 31 Mar 2014 at 6:53am |

I like the idea of having a machine shop fabricate new press on rings for the idler wheels. I may investigate that further. For now I made a tactical decision to put it back together as I need the dozer for some small projects that cant wait. I was able to make the sliding action of the idler wheel bearing blocks work smoothly and greased them up. With some effort and clever use of winch cargo straps, I was finally able to put the track back on. The hydraulic grease tensioners are working on both sides. Now that I understand how they function and where to apply the grease to make them move. They work wonderfully. I have nice properly tensioned tracks!. Im still carefull on turning out of habit, but I didn't throw a track all day! I was wonderful. Pictures to follow.  |

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 7:36am Posted: 31 Mar 2014 at 7:36am |

|

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8752

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 10:16am Posted: 31 Mar 2014 at 10:16am |

|

Very interesting and informational thread. I have an HD5G of my own that is waiting for me to work on, however the main area in need of attention on it is the steering clutches. Just seeing someone else making a machine functional, gives me more enthusiasm to get going on mine. I wish I had mine operational now, as it would be getting used daily cleaning corrals. Darrel

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 10:48am Posted: 31 Mar 2014 at 10:48am |

You need to get some counterweights on the back of that machine - it is way out of balance with a loaded bucket . Mine has 2 weights a thick and thinner one .

The auxiliary fuel filter just doesn't weigh enough for a counterweight !

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 10:49am Posted: 31 Mar 2014 at 10:49am |

|

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 2:06pm Posted: 31 Mar 2014 at 2:06pm |

@ Coke in MN, Yes you are right about needing counterweights! Mine has none. But id thought about adding a frame to hold two 55 gallon drums. Then filling them with water. That way they can be removed easy enough if needed. Just drain them. What do you think?

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 2:12pm Posted: 31 Mar 2014 at 2:12pm |

@ Darrell in ND, Ive had one of my steering clutches out and apart before. You have to pull the fuel tank to get to the cover plates. Its not to bad to get out. Kinda heavy. Anyway, the clutch was frozen with rust. Had to beat it apart and replaced the friction discs and 1 of the metal discs. Alot of carefull removal of rust from the teeth later and I had it working again. When I got my HD5G it had been sitting in the woods for many years in pieces. Rain had gotten into everything but the engine. I had it running shortly after bringing it home. Had to drain water from gearboxes and rebuild the right side final drive. Its been a good worker though and owes me nothing as I paid very little for it. I m happy to have it.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2014 at 9:30pm Posted: 31 Mar 2014 at 9:30pm |

Water would work but then the problem with ice chunks in colder weather . Be sure there are no plugs in bottom of clutch / brake housings in the 3/4 pipe plug holes .and keep the cases clean inside so water can drain out . If you do not have a grease hose to the throw out bearing for steering clutches - add one to be able to grease them without opening case .

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8752

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Apr 2014 at 7:39am Posted: 01 Apr 2014 at 7:39am |

rwhendrix wrote: rwhendrix wrote:

@ Darrell in ND, Ive had one of my steering clutches out and apart before. You have to pull the fuel tank to get to the cover plates. Its not to bad to get out. Kinda heavy. Anyway, the clutch was frozen with rust. Had to beat it apart and replaced the friction discs and 1 of the metal discs. Alot of carefull removal of rust from the teeth later and I had it working again. When I got my HD5G it had been sitting in the woods for many years in pieces. Rain had gotten into everything but the engine. I had it running shortly after bringing it home. Had to drain water from gearboxes and rebuild the right side final drive. Its been a good worker though and owes me nothing as I paid very little for it. I m happy to have it. |

I have worked on the steering clutch on one side of an HD5 about 20+ years ago. I hope I can jar loose some old info in my brain to get er done again. I only paid $400 for my 5G a couple years ago on an auction. It does run good, but kind of useless right now when it only will go in a straight line. LOL! When I bought it, I could have hauled it 4 miles from the auction site to the scrapper and made a very quick $1,000 to $1,200, but I just couldn't bring myself to do that. So it is at my house waiting for me to find the time to work on it. I actually am very much looking forward to the project, as my 16 year old son is enthused to help me on it, and it will be a good father/son project. Darrel

|

|

rwhendrix

Bronze Level

Joined: 09 Jan 2014

Location: Indiana

Points: 43

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Apr 2014 at 12:31pm Posted: 01 Apr 2014 at 12:31pm |

$400 is a very good price. I paid $500 for mine in 2005 off Ebay. Cost me that much again to get home. After parts and repairs another $1000 or so, I have a working machine. Not like new, but it has paid for itself again and again over the years. A good investment that I enjoy.

|

|

SHAMELESS

Orange Level

Joined: 13 Sep 2009

Location: EAST NE

Points: 29486

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Apr 2014 at 3:07am Posted: 02 Apr 2014 at 3:07am |

|

the left track always came off mine too when doing the same thing, always suspended the unit in the air and pryed it back on, I found the tenshioner bolt had run outta threads to keep it tight nuff, took it out, had a machine shop lengthen it...can't remember how much...thinking it was about 2-3 inches, put it back on, adjusted it and never had anymore problems! the reason I had it done, was that the previous owner had done the same thing on the right side!

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8752

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Apr 2014 at 5:08am Posted: 02 Apr 2014 at 5:08am |

SHAMELESS wrote: SHAMELESS wrote:

the left track always came off mine too when doing the same thing, always suspended the unit in the air and pryed it back on, I found the tenshioner bolt had run outta threads to keep it tight nuff, took it out, had a machine shop lengthen it...can't remember how much...thinking it was about 2-3 inches, put it back on, adjusted it and never had anymore problems! the reason I had it done, was that the previous owner had done the same thing on the right side! |

Shameless; what you doing up at three in the morning? Ole lady (oops, I mean your loving wife) kick you out of bed? Anyhow, do you still have that outfit? Darrel

|

|

hd5itis

Bronze Level

Joined: 21 Apr 2014

Location: covington va

Points: 5

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2014 at 8:41pm Posted: 21 Apr 2014 at 8:41pm |

|

hey fellas , I am new here , just received all new steering clutch parts in the mail for my hd 5 and have been sand blasting all of my hub parts and getting ready for the rebuild . the engine only has 21 hours on it since it was rebuilt ,getting a lil excited!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

rwhendrix wrote:

rwhendrix wrote: