| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: New Member with HD 5G problem Topic: New Member with HD 5G problem

Posted: 23 Feb 2016 at 4:59pm |

|

Hello everyone! I just signed up...I have been reading the forums here quite a bit, and am very impressed with the knowledge and willingness to share that knowledge!

I inherited a HD 5G (serial 17928) from my father last year, and have been going through it to get it up in better shape...but I have just discovered a large (for me) problem...

After much research here on the forum, I decided to grease the truck rollers, idler, and outboard drive bearings...and while all the others were full of grease (thick...I pumped in OO corn head to push out as much as possible of the old)...both outboard final drive bearings were dry (or more like "old" grease that was almost dirt-like solid) and many small pieces of metal and a roller or two was dug out of the left side one...

I am pretty mechanically inclined, and have a fair shop...but not sure I am going to have the experience necessary for the repairs...I am going to need some advice and help along the way and would really appreciate anything anyone has to offer! I wanted to ask some questions before trying to tear into this project. I guess I'll start with...Are all parts, seals, shims etc I will need available, and if so where? (I am praying the shaft is salvageable)

Also, is it possible to do the repairs (assuming shaft is ok) without removing the track and truck frame?

Thanks in advance for reply's!

|

|

|

Sponsored Links

|

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 41947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Feb 2016 at 5:40pm Posted: 23 Feb 2016 at 5:40pm |

to fix inboard bearings or seals it is necessary to remove truck frame - thus the track also , to remove the sprocket you will need much torque on nut and to replace also . Bearings on outboard of axle on truck frame is a link belt unit and hard to find except through someone with access to used or NOS parts - Moving the truck frame on doser is not as big a problem as on G - I ended up doing a jig, cut, weld on machines for rear of frame . somewhere in old posts is explanation of how .

truck rollers are timken bearings as are front idler bearings - not bushings like most machines - outboard rear bearing is suppose to get lube through axle and from rear housing reduction gears .

|

|

Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something.

"Challenges are what make life interesting; overcoming them is what makes life meaningful."

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Feb 2016 at 5:55pm Posted: 23 Feb 2016 at 5:55pm |

|

Thanks! I think the problem is confined to the outer bearing only...I don't see any evidence of inner (inside track sprocket) problems. Can I do the repairs on the outer carrier/bearings/housing without removing or relocating or cutting truck frame?

I am thinking also that by serial number, this one is not the drilled axles?...has the 3/8 pipe plug for lube...removing this plug is what lead me to the discovery of the metal pieces.

Do you have someone or some place you can recommend for the link belt bearing? What about seals and shims I will need? Are those available? I am not sure about even starting to tear this down until I can source some parts.

I also read one of your posts about having the outer bearing case machined and a steel insert for a different bearing installed? (post was about a different machine, not an HD 5, but is this a possibility?)

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 41947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Feb 2016 at 6:11pm Posted: 23 Feb 2016 at 6:11pm |

Lot of things are possible - just if practical I had a HD5B i ran for a bit by modifying the outer bearing but ended up replacing axle and outer bearing later - back to stock . You will need to tear it down to find what parts you need - so kind of hard lining up things first . IVAN might have parts , I have one axle and might have outer housing but unsure .

|

|

Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something.

"Challenges are what make life interesting; overcoming them is what makes life meaningful."

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Feb 2016 at 6:27pm Posted: 23 Feb 2016 at 6:27pm |

|

Thanks again for reply!

I suppose I have no choice but to disassemble and inspect...was just hoping to line up at least what I know is shot! The bearing is definitely a goner! I will try and contact IVAN as recommended. Thank you!

The manual I have does not specifically address the removal/replacement of just the outer bearing housing....it is included as part of the removal for the sprocket. Can I remove just the housing/bearing/seal assembly or does the axle shaft/sprocket and all have to be removed as well?

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1013

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2016 at 5:53am Posted: 24 Feb 2016 at 5:53am |

|

You have to removed the cap from the cage and the nut from the axel and loose the cap bolts from the track frame pivot and jack the machine and you should be able to removed the outboard cage ass withe a puller

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2016 at 7:04am Posted: 24 Feb 2016 at 7:04am |

|

I added to my 27 August, 2014 post so you can see the inside of the bearing cage. The available bearing has a larger outside diameter. The bearing housing can be bored to accept the larger diameter if you can not find the original bearing.

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2016 at 8:02am Posted: 24 Feb 2016 at 8:02am |

|

Thanks all for the replies! I searched on this topic before posting here and couldn't find much...mostly due to my unfamiliarity with forum search methods! DOZER, I searched posts by member name and found your posts on the outer bearing replacement...great post!!!! Really appreciate the post and pics! Answered many questions. I am hoping to get mine torn down in next couple of days...I will try and post pics along the way also.

I am concerned that I may have damage to the threads, if not bearing surface on axle, just judging from the amount of "debris" metal and pieces of roller from bearing that was jammed in grease hole behind the plug...

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Feb 2016 at 9:49am Posted: 25 Feb 2016 at 9:49am |

So I got the outer cage covers removed on both sides... uploads/15072/47.JPGAnd after a little cleaning... uploads/15072/50.JPGIt appears that the axle may be ok. The bearing and nut obviously is not! Now I have a question...since pulling the bearing cage from the axle with a puller involves a puller pushing the shaft thru while pulling on the outer cage housing, and the bearing has disintegrated and there is no mechanical connection between the inner race and the outer race...when I pull won't that then force the seal assembly and everything behind the inner race to press on the inner race remains only? And therefore damage or destroy what is left of the seal assembly? Of course with the bearing being shot, maybe there is nothing left of the seal assembly anyway at this point?

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3800

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Feb 2016 at 10:06am Posted: 25 Feb 2016 at 10:06am |

not sure on the Hd5 but if its similiar to the larger dozers it has a should have a positive type seal not a lip seal (think ceramics in a water pump seal). the diameter should be large enough to clear whats left of your inner race just be careful and keep an eye on the rubber bellow, but it may already be shot. the metal sealing surfaces are usually fine, its the rubber that goes bad and lets things leak.

Edited by CAL(KS) - 25 Feb 2016 at 10:09am

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Feb 2016 at 11:14am Posted: 25 Feb 2016 at 11:14am |

|

The seal is inboard of the bearing. Remove the bolts holding the bearing cage to the truck frame. Raise the rear of the machine to take the weight off the bearing cage. Pull the bearing cage off the axle. The pictures I posted were from my HD6G. The axle on your HD5 is supposed to be the same as the early HD6. Your pictures look as if the bearing is smaller. The AC part number for the bearing on my HD6 is 080101. Is this the same number for the HD5??? The bearing cage cap on your HD5 has 5 bolts. There are 8 bolts on my HD6.

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1013

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Feb 2016 at 2:24pm Posted: 25 Feb 2016 at 2:24pm |

|

Like dozer said remove the outboar bearing cage bolts and loose the diagonale arm track frame cap bolts and raise the back machine and with a bad bearing like that maybe you can removed the cage with out puller and the bearing is the same from HD6 but not the cage

|

|

wayneIA

Orange Level

Joined: 17 Oct 2009

Location: Waverly, IA

Points: 268

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Feb 2016 at 12:28am Posted: 26 Feb 2016 at 12:28am |

|

If I remember right, I got my new bearings from Thill Track and Tractor in Wisconsin. If it wasn't there, then it was Draper Tractor in Washington state. While your at it, put new seals in too. But hang on for the cost of the bearings, they are a double cup and cone self-aligning bearing. While you have your bearing housing off, make sure that the sprocket nut is tight, if I remember correctly the torque spec. is 1500 foot pounds.

Edited by wayneIA - 26 Feb 2016 at 12:30am

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Feb 2016 at 3:51pm Posted: 26 Feb 2016 at 3:51pm |

Got it all apart...well, mostly. Here are the all that's left of the bearings and seals...   Left side, the axle and sprocket nut...  On the right, notice there is still part of a seal or ?? next to the sprocket nut. It moves slightly but does not want to slide off. How do I remove this?  Second question...the threads are good on the axles...seal surface is wiped out. I do not have the time nor the money to remove the axles. I believe I can rig a jig similar to what DOZER did to recut threads, and grind the seal surface area down and install a sleeve. Has anyone ever done this and are there sleeves available? Or do I need to fabricate the sleeve? Or are there other fixes that I am not aware of?

Edited by Chas55 - 26 Feb 2016 at 3:54pm

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1013

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Feb 2016 at 4:34pm Posted: 26 Feb 2016 at 4:34pm |

|

The spocket nut have a lock nut with 2 bolts you should clean the big nut maybe they weld'it on sprocket and the big nut must have a shoulder like the right side for the ring seals and the spring ass, with boot and if you can removed the lock nut try to turned the big nut with out tension on sprocket and you will see if the shaft tread still good

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Feb 2016 at 4:39pm Posted: 26 Feb 2016 at 4:39pm |

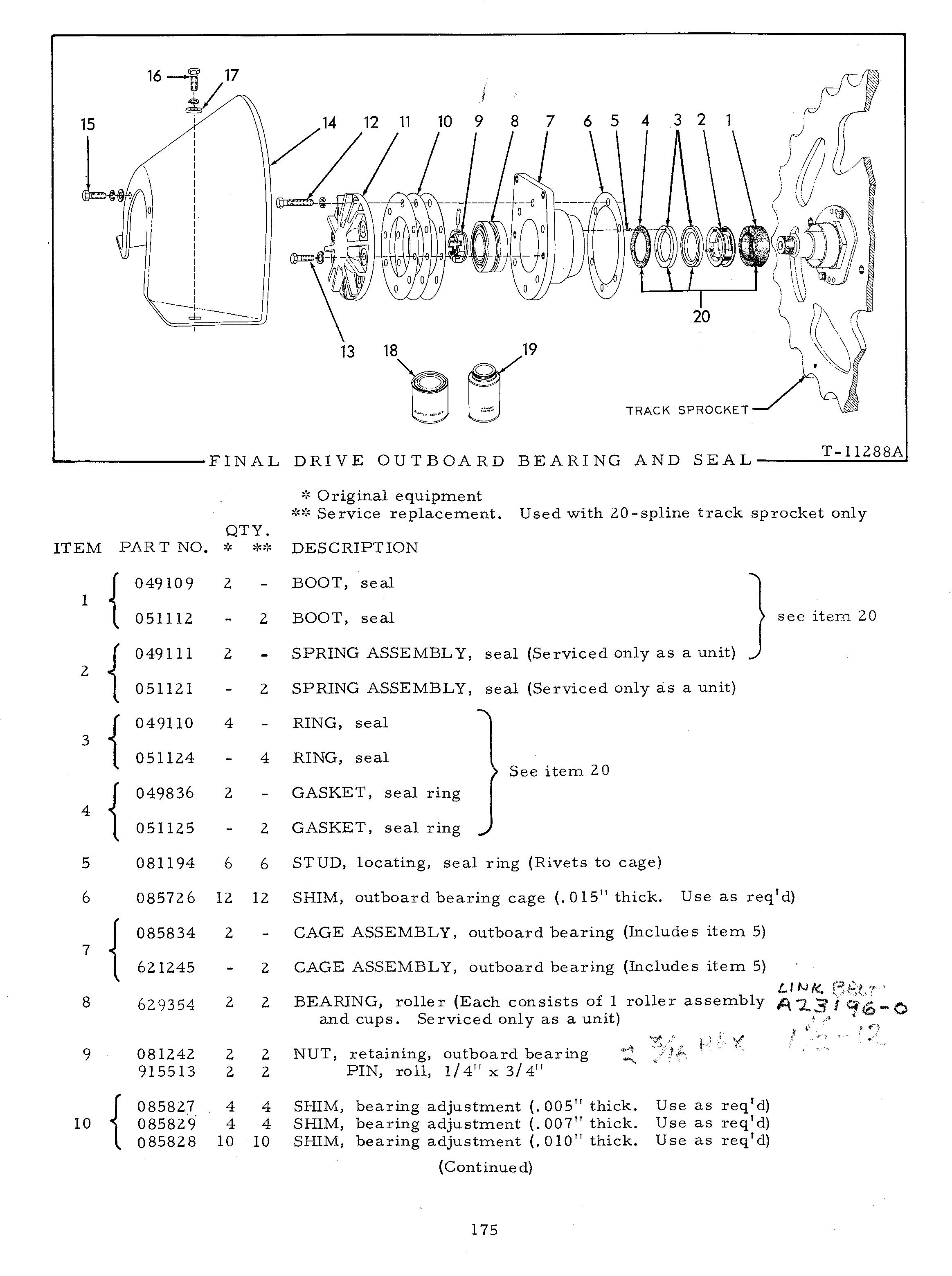

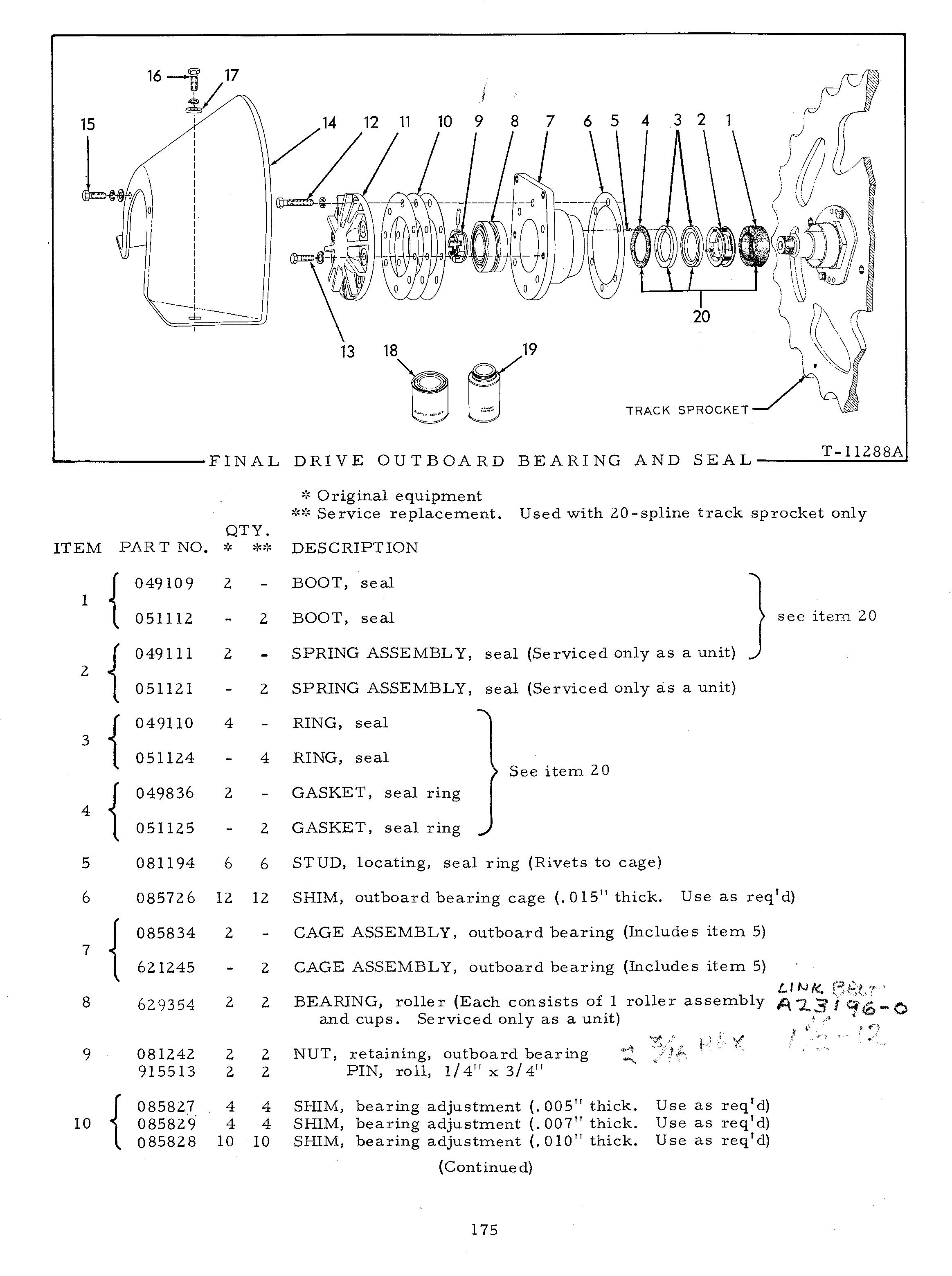

From the HD6G parts book. There is a lot of axle material worn away. The axle diameter inboard of the bearing surface is 2.500" The seal is positioned inside the sprocket nut. The sprocket nut looks to be damaged or part of the seal assembly is inside the nut. There is a lock washer that is bolted to the sprocket with 3/8-16 bolts. There should be one rubber ring and a steel ring glued to the inboard side of the bearing cage. Hope the picture helps.

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Feb 2016 at 11:49am Posted: 27 Feb 2016 at 11:49am |

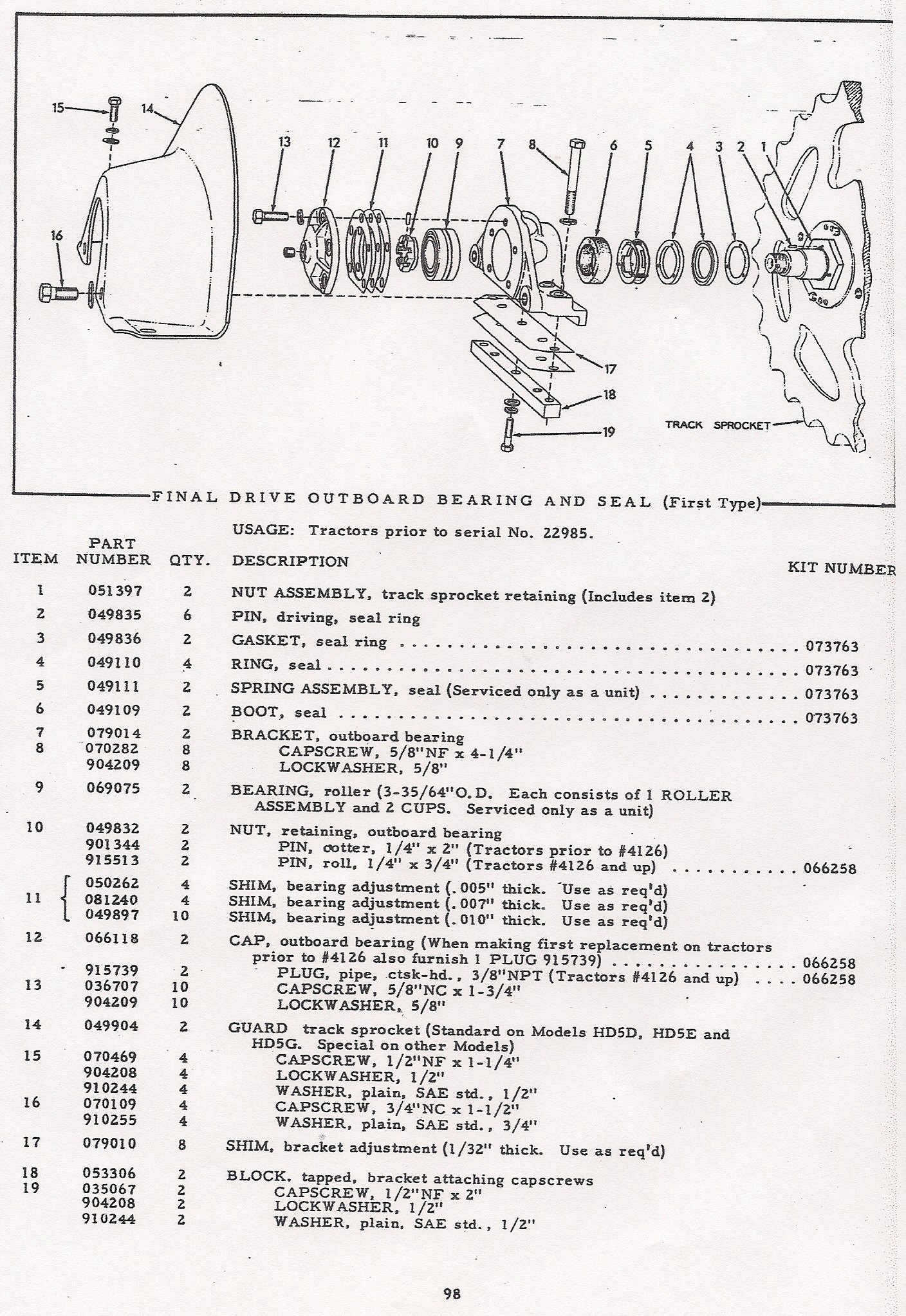

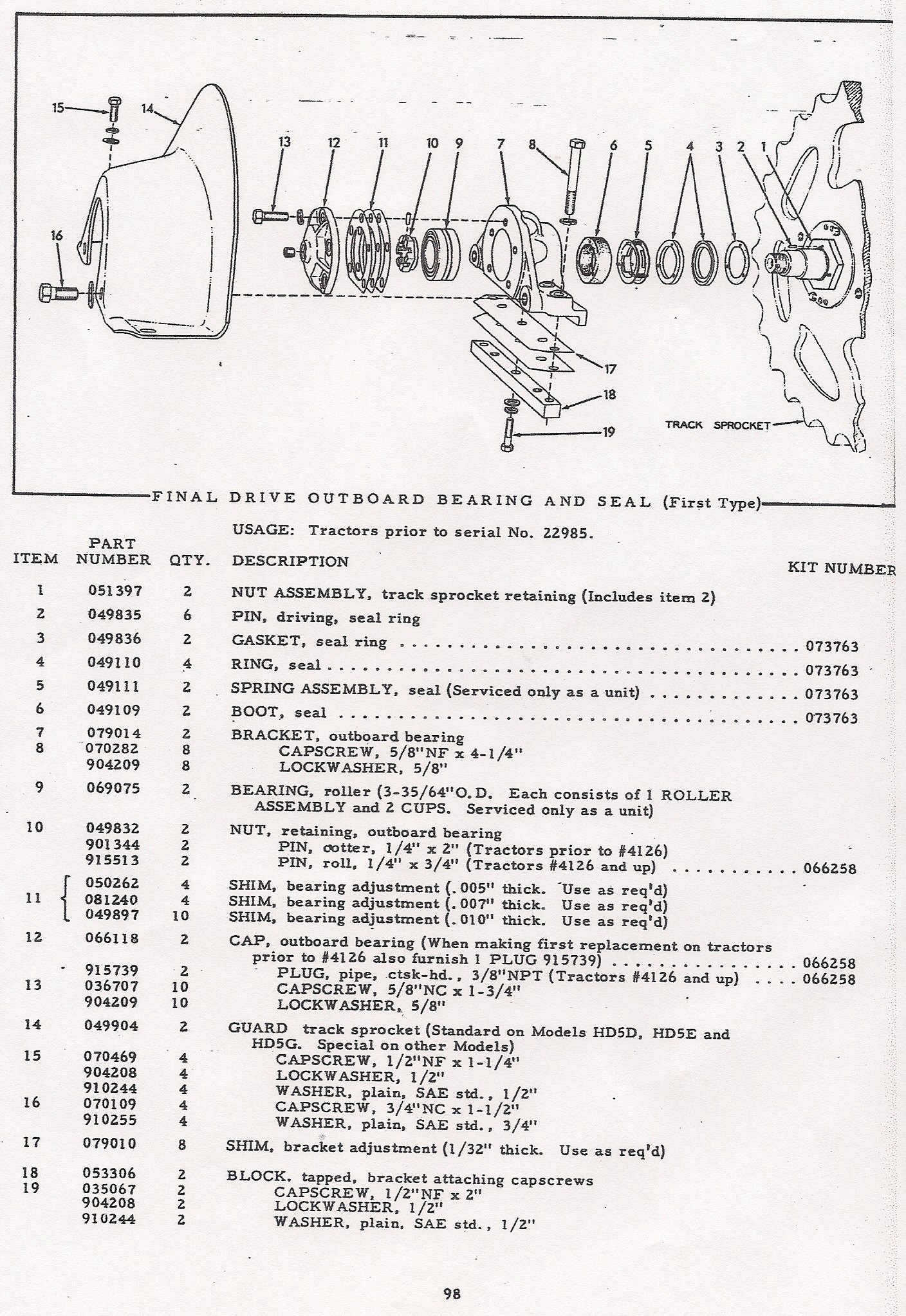

Thank you everyone for the responses! I will clean and check sprocket nut torque...good suggestion! Dozer...the following image is one of two listed in my parts book...according to serial number, and by the look of the axle nut area, I believe this is what I have instead of the second type, which changed up after serial number 22985...and probably includes your HD 6. The part number for the bearing appears to be different, but sounds like Gemdozer and others agree they are the same bearing?  So, at this point, the left side axle nut does not show any of the three "pins" shown in my drawing...they may be broken off and I am just not seeing where they are...I will clean the nut up and look for that next...seems like they must be there if I truly have the first type...and by the looks of the right side, it seems to confirm that...however I have not pried to hard on the remaining seal assembly on the right yet... Can someone confirm that the axle diameter at the seal surface is the same as the 2.500" Dozer has on the HD6? If I am going to make or find a sleeve to repair the seal surface, I need to make sure of the dimension. Dozer, would it be possible to get some more information on how you built your jig for the die grinder? I have a older DUMAR toolpost diegrinder that mounts with a machined sleeve surface I intend to use...and of course I will be grinding inboard of the bearing surface whereas you were doing the thread area. I will need to be able to adjust for both diameter and depth...My machinist skills are mostly at the hobbyist level but I believe I can hold tolerance on the grind to 0.010 or better. But if not, I am assuming that I can have a fairly large error tolerance on runout and taper since this is just a seal riding on it...and at low rotational speed.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 41947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Feb 2016 at 4:51pm Posted: 27 Feb 2016 at 4:51pm |

HD5 and HD6 axle is the same - early axel had rifle drilling to lube bearing - there are fine spline and large spline axles - later machines used the large spline . The rear housing on the HD5 and HD6 are the same casting on both machines and much of parts internal are the same . Steering clutch innards from a other AC machines will fit into 5 and 6 drum

AC also used similar parts on machines in other areas as well as parts from open market rather than special made for their use only .

|

|

Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something.

"Challenges are what make life interesting; overcoming them is what makes life meaningful."

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 535

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Feb 2016 at 7:52pm Posted: 27 Feb 2016 at 7:52pm |

|

the seal does not ride on the shaft. it sits against the nut, should have 3 holes that engage the end of the seal to the nut. glue seals it to the nut. then the stationary section sits in the bearing housing. like said earlier, think of a ceramic pump seal style. has a spring assembly that puts pressure on the seals to keep them together. I know general gear has new seals and nuts. best to have the nuts that have the shield on them to keep the stuff out of the seal. looks like you have the first style with the stationary side on the nut. the second style like the pic has the stationary side in the bearing housing. keep them greased but not too much pressure or the bellows will blow out. good luck and post a pic of the entire machine.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Feb 2016 at 7:52pm Posted: 27 Feb 2016 at 7:52pm |

Ok...got the nuts cleaned up and the "ring" off the right side...it wasn't a seal, just a steel ring...part of the seal?  and the side with good pins still in place...  So...this is first style? And, I measured the axle at the area directly under this ring...and it was 2.250"... I have located both new and used bearings, and most of the seals...just would like confirmation that the bearings and seals are identical between the 5 and 6 as I believe the used bearing are from a 6. I am going to try and salvage my axles for now. Thinking about a product recommended by Ivan called Belzona...since it is just the seal surface area that is in poor shape. Has anyone had any experience with that? Or, I may grind that area and install a sleeve...still looking at options...and opinions!! Thanks!

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Feb 2016 at 8:00pm Posted: 27 Feb 2016 at 8:00pm |

|

Dadsdozer...THANKS...that clears a lot up. I didn't see your post until after I posted my last one...

Question...can I switch to the second type seals then and keep the stationary part in the housing? Other than the nut and the shield, are the rest of the seal parts identical and just directions are reversed? One of my housings has the inside "lip" where I assume the seal presses against almost completely worn away for about 1/3rd the diameter...if I can switch directions and put the stationary side of a seal there, I think I can salvage it!

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Feb 2016 at 11:27am Posted: 28 Feb 2016 at 11:27am |

Dadsdozer... I researched the seal layout of the two types...first and second, and it appears the only difference is the shield on the nut and the direction of installation...but I have to confess I have not messed with a water pump type seal in 40 years! So I am still trying to wrap my head around the way this seals...I get that it doesn't seal on shaft...but where exactly is the interface between the stationary "seal" and the rotating "seal"? Which parts rotate and which are stationary? in the parts diagram, several things are listed with the word "seal"...so I am unclear. On disassembly, one side on mine still had a metal "ring" with the holes for the pins on the nut, and was against the nut. No gasket...maybe glue? Is that the "metal" side of what's listed as item 4 (first style) and the second piece of item 4 is the actual "seal" and this is where the stationary and non stationary items meet? Also, it appears that the boot seal (item 6) which in first style sits in housing, has three holes...are there supposed to be pins in the housing to keep it from rotating? And is it supposed to seal against the "lip" in the housing? The reason I am concerned is both of my housings are somewhat "chewed up" on the seal side...the lip is fully present on one and can be cleaned up on the mill...the other (pic below) is not in very good shape... I am trying to understand exactly how this all works so I can possibly "fix" the housing! Maybe if someone could send or post a pic of a good housing (seal side) from a first style?? I inherited this 5 from my late father, and do not foresee putting many hours on it in a year, but would like to fix it to the best of my ability, considering my limited finances. Thanks again everyone for the help!!!

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 535

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Feb 2016 at 3:23pm Posted: 28 Feb 2016 at 3:23pm |

|

the metal ring you took off of the nut is part of the seal. the sealing is done by glue and a gasket on the nut on the sprocket. the other side of the seal is where the oil is sealed as it rotates. the other half of the seal is glued into the housing with a gasket to seal it to the housing and then the bellows has a spring in it that pushes the seal toward the other half. no part of the seal actually touches the shaft. it does not matter that it is chewed up, you do not need a sleeve. it is a different type than a lip seal. both ends of the seal have 3 pins that engage them or hold them in place. depending on which style is used is the direction the seal is installed. either direction uses the same seal to my knowledge. the sealing surfaces are polished to not allow any oil to get by. the housing you have may not be salvageable as it is worn too much to hold the sleeve. I see no pins or holes to put pins in to drive the seal. I would recommend changing the sprocket nuts to the style with the cage on it then the bellows end of the seal goes in there. you may be able to salvage the housing so the steel ring will hold into it. I changed my seal last year and I will look for pics I took and post. think of taking 2 coffee cans and holding them together end to end. the bottoms of the cans is where the oil is sealed and one of them rotates and the other does not. in hope this makes it a little clearer.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 535

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Feb 2016 at 8:05pm Posted: 28 Feb 2016 at 8:05pm |

these pics are of the nut with the shield, one with the seal installed and one without. these are all I can find.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2016 at 8:09am Posted: 29 Feb 2016 at 8:09am |

|

Chas55's

The seals on your HD5 are installed backwards of how we are accustomed to seeing them. Your axle nut has pins for driving the steel sealing ring. The pictures Dadsdozerhd5b posted shows the more common axle nut that has a cylindrical boot shield. This axle nut has 3 holes that drive the boot and spring assembly. The boot and spring assembly is glued to the inside of the axle nut. Booth use the FIRST TYPE ORIGINAL EQUIPMENT SEALS. The second type seal is used on the 20 spline service replacement (second type axle) that you do not have.

Both axle nuts should be replaced with # 081369 that has the boot shield.

The bearing cages should be replaced because the portion of the cage that supports the seal is worn away. The replacement cage should have the (3) pins that hold the steel sealing ring and rubber gasket stationary.

As stated earlier the worn part of the axle does not have to be built up because it in not important to the lubrication seal.

|

|

Chas55

Bronze Level

Joined: 23 Feb 2016

Location: Springfield MO

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2016 at 8:39am Posted: 29 Feb 2016 at 8:39am |

|

Thanks Dozer!!! Great information! I sent you a email regarding some of this just a few minutes ago! I am going to try and source the nut you mentioned...but had the thought that maybe I could machine and tack weld a sleeve to my existing nut and turn the seals around...That would save a lot of expense and work...wouldn't have to remove existing nuts (purchase large socket to do so) and I am slightly apprehensive about the torque required to re-install...1200 or 1500 ft lbs I hear...I have a torque multiplier and a 300 ft lb torque wrench, but the way my luck goes, something could mess up and I am afraid of stripping threads, snapping an axle, or not getting it tightened enough and it works loose and causes damage!

I am also trying to find a used housing reasonably priced...one I have is salvageable. The other badly damaged one I could bore and machine an insert with a new lip and pins for, if I had to, but very time consuming!

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3800

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2016 at 10:24am Posted: 29 Feb 2016 at 10:24am |

|

to get the high torque is actually not too hard and should be out lined out in your manual. On my 16 you release the opposite side steering clutch and put the trans in 1st gear. turning the nut on the input shaft of the trans to a certain torque puts out the 2000lbs of torque needed to tighten the sprocket nut. you just need to make a wrench to hold the big nut.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 41947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2016 at 11:05am Posted: 29 Feb 2016 at 11:05am |

|

48" pipe wrench - 10' section of pipe to slip over handle of pipe wrench - 6 to 7 ft out from center of jaw of wrench 200 lb of weight applied = 12 to 1400 ft lbs torque

|

|

Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something.

"Challenges are what make life interesting; overcoming them is what makes life meaningful."

|

|

ivan

Silver Level

Joined: 12 Sep 2009

Location: NE Michigan

Points: 319

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2016 at 12:09pm Posted: 29 Feb 2016 at 12:09pm |

|

I sent you a quote on the seal and nut

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)