| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: I'd like a tube of Nu-Thread please Topic: I'd like a tube of Nu-Thread please

Posted: 27 Aug 2014 at 7:03pm |

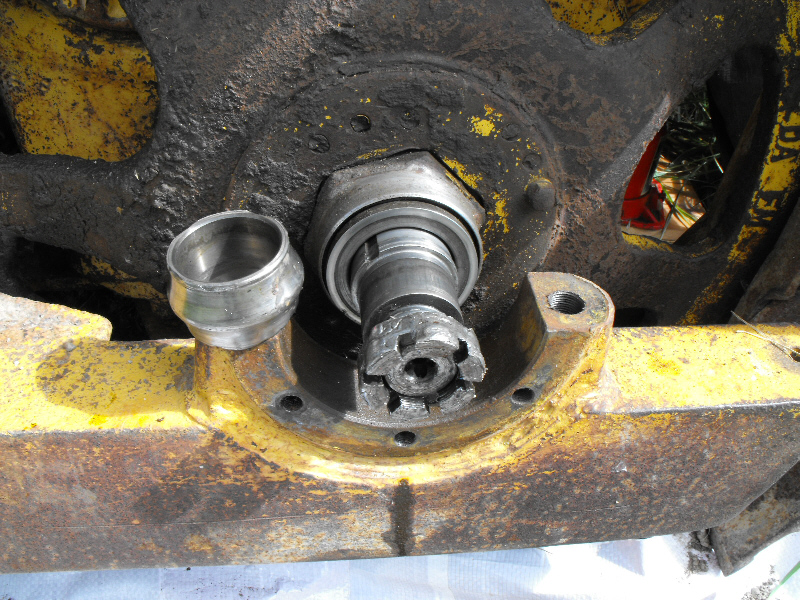

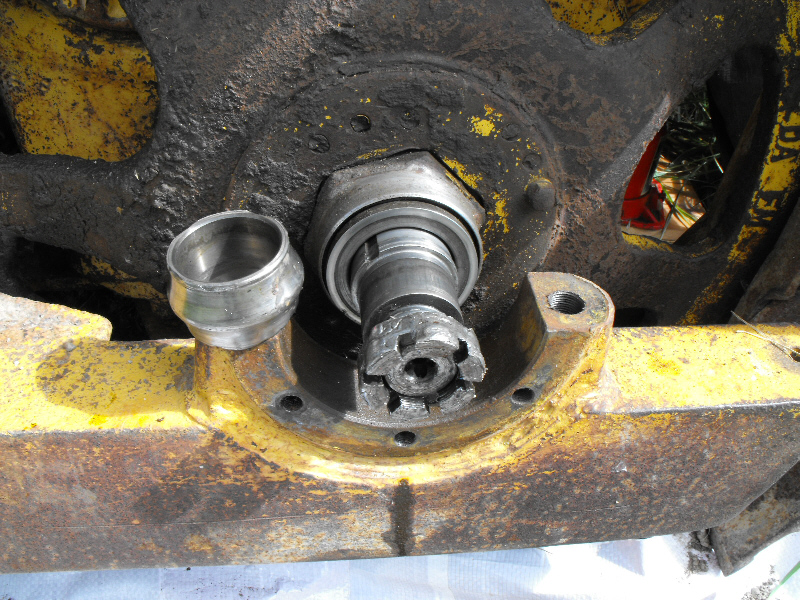

Last time I used my HD6G I noticed final drive oil on the sprocket. It shouldn't take long to replace the outer seal RIGHT??? I need both internal and external Nu-Thread. The hex nut doesn't have 6 points it is sorta rounded.   Is there any way I could cut another thread and fabricate a special nut? Any suggestions??? Enjoy the pictures

|

|

|

Sponsored Links

|

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 53864

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2014 at 8:17pm Posted: 27 Aug 2014 at 8:17pm |

|

You could re-thread it smaller, but you gots a whole heap of dis-assembly and inspection to do first! Bearing surface is prolly buggered up, too...

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 53864

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2014 at 8:44pm Posted: 27 Aug 2014 at 8:44pm |

|

If the bearing surface is OK, Here is what I would do: Put a bushing in the center hole, and take a new hole saw, and cut off the old threads, then re-thread it. Important part is sizing of the hole saw, and finding a standard size fine thread die. I'd try them out on a sacraficial piece of aluminum scrap shaft. Still gonna be a bugger to get it started straight...

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 53864

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2014 at 8:47pm Posted: 27 Aug 2014 at 8:47pm |

DiyDave wrote: DiyDave wrote:

If the bearing surface is OK, Here is what I would do: Put a bushing in the center hole, and take a new hole saw, and cut off the old threads, then re-thread it. Important part is sizing of the hole saw, and finding a standard size fine thread die. I'd try them out on a sacraficial piece of aluminum scrap shaft. Still gonna be a bugger to get it started straight... |

Oh, and get the new bearing and seal, and possibly a speedy sleeve, if the seal surface is buggered... Have them on hand, prior to any cutting/sizing decisions are made...

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2014 at 9:03pm Posted: 27 Aug 2014 at 9:03pm |

|

It can be threaded and special nut made. Needs to come out, take pics and post. Might be a nut close enough that you can just rethread the shaft. Might be cheaper to get a used part. HTH Tracy Martin

|

|

No greater gift than healthy grandkids!

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2014 at 11:22am Posted: 28 Aug 2014 at 11:22am |

More pictures: Today I removed the outboard bearing cage. The bearing surface on the sprocket shaft is not damaged. The threaded area is 0.10 undersize. I can file the shaft so it is below 60 Rc. I am considering welding the shaft and recutting the 1 1/2-12 thread. To do this I need to move Allis to where I can weld. (sugestions ???) I'm considering TIG welding with 304 stainless rod. I have had luck welding on high carbon steel without the weld cracking. (sugestions)

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 41947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2014 at 3:11pm Posted: 28 Aug 2014 at 3:11pm |

I removed the full axle , put in lathe and re threaded shaft to next size down . I also have a complete axle from HD 5 (same as HD 6) which is std size here . Welding can have problems as it changes stress points in axle and can lead to failure . Had 3 HD4 axles break where they had been welded to build up seal surface area but crystallized material which led to failure.

|

|

Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something.

"Challenges are what make life interesting; overcoming them is what makes life meaningful."

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2014 at 6:15pm Posted: 28 Aug 2014 at 6:15pm |

|

If I have to take the shaft out I will look for another shaft. This machine has the 3 3/4 sprocket nut. I think this means it has the 20 spline shaft. I am making an oak bearing that I will soak in oil so I can move the machine to work on it. I don't want to split the track, disconnect the truck frame to roll it out of the way so that I can remove the sprocket. The concept of cutting the truck frame and welding it back together rubs me the wrong way. I do appreciate any comments.

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2014 at 8:54pm Posted: 28 Aug 2014 at 8:54pm |

|

The 20 spline shafts were way less habitual with breaking the ends off like the coarse spline ones did. You gotta spare outboard bearing George?

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2014 at 9:17pm Posted: 28 Aug 2014 at 9:17pm |

|

You could take a portable boring head and turn boring bar around and turn shaft to thread size. Use an acorn type die and thread the shaft. All of this would need squaring of mill to work piece. There is plenty of room to do it there also.Probably easier this way than dismantling machine. Might even rent the mill. HTH Tracy Martin

|

|

No greater gift than healthy grandkids!

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Aug 2014 at 8:54am Posted: 29 Aug 2014 at 8:54am |

|

The portable mill idea is interesting. I have no idea where to rent one. Who makes a portable mill? I do not have a replacement bearing. The old one is damaged where the part number was. The Link Belt bearing is unusual. I wonder what AC was thinking when they chose it. I no longer have my printed bearing catalogs. On line catalogs are far less than as good as the printed versions. I'm considering a 50mm ID x 100mm OD spherical roller bearing as a replacement. I'm searching for a part number. Thanks for the suggestions.

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Aug 2014 at 5:02pm Posted: 29 Aug 2014 at 5:02pm |

|

Cant get the bearings down here anymore so we use one with the same bore for the shaft, but larger O.D. which means machining housing out to take it. All very expensive. If you can get a good one from a tractor salvage yard would be best cost wise, even if you have to look a long way out of state. An old timer on AC crawlers told me they cannot lube properly with that drip feed from final drive. He showed me how to put a grease zerk on the end cap where it recesses a bit to protect it. Use grease with no fancy additives so it will blend with the final oil if over greased he said. In the years I followed his advice, I never again had an outboard bearing fail (HD6 and HD11 tractors)

Edited by Mactractor - 29 Aug 2014 at 10:08pm

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1013

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Aug 2014 at 2:33pm Posted: 30 Aug 2014 at 2:33pm |

|

I am still have some outboard cages with bearing for HD6

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2014 at 9:19am Posted: 06 Nov 2014 at 9:19am |

The repair is complete. I made a fixture that locates on the bearing surface and holds my diegrinder to cut the damaged threads down to a smaller sized thread. The fixture is adjustable for cutting the shaft diameter using a carbide burr. It is manually rotated and translated on the bearing surface.  The original 1 1/2-12 thread was recut 1 7/16-12. This is a standard size but I was unable to find one. I located the 1 7/16-12 tap and die on eBay. I made the special castle nut.  I made the die stock to locate on the bearing surface so that the thread would be aligned properly. I cut a 1/8 NPT thread in the bearing cap to pre lubricate the bearing. Thanks to everyone for comments.

|

|

chumduffy

Orange Level Access

Joined: 28 Sep 2013

Location: Smethport, PA

Points: 4951

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2014 at 9:39am Posted: 06 Nov 2014 at 9:39am |

|

WOW!! Great job!! Smart thinking!! Chum.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34281

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2014 at 9:52pm Posted: 06 Nov 2014 at 9:52pm |

I really like that ingenuity... Better hang that handy dandy tool up on the wall for the next time somebody has the same issue with theirs... Then rent it out and make a fortune selling those "special nuts"

I like the die grinder idea too, but I think I would have opted to have a carbide cutter to be put in the tool you made for cutting the threads down, then put the die in and finish the job... I applaud you in your success. Best part, you had pictures to show too...

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2014 at 5:36am Posted: 07 Nov 2014 at 5:36am |

|

Thats clever George. Very well done. Maybe with your ideas, I could have saved some of my junked shafts

|

|

albatros_3

Silver Level

Joined: 16 Apr 2012

Location: SE Michigan

Points: 450

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2014 at 8:47am Posted: 07 Nov 2014 at 8:47am |

|

Wow, that is impressive!

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2016 at 6:57am Posted: 24 Feb 2016 at 6:57am |

|

This is the same bearing cage as on the HD5G. Many people put a grease fitting on the cover. I did not have enough shims for adjusting the Timkin bearings so I put a shim in my scanner and printed it on heavy paper or gasket material to cut out the shims.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DiyDave wrote:

DiyDave wrote: