| Author |

Topic Search Topic Search  Topic Options Topic Options

|

olderironguy

Bronze Level

Joined: 16 Oct 2013

Location: missouri

Points: 7

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Cheap WD build Topic: Cheap WD build

Posted: 16 Oct 2013 at 5:31pm |

|

Ok this is the first time I have ever posted on a forum, but I am in search of the cheapest way to build a WD engine for pulling and still be competitive. I have been doing a lot of research and so far have just confused my self.

I have read that you can use Farmall rods with chevy pistons and stroke a wd45 crank is this true. A little help for the beginner would be nice.

|

|

|

Sponsored Links

|

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3786

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2013 at 5:51pm Posted: 16 Oct 2013 at 5:51pm |

yes what you listed will work. depends on budget. countless combinations, covered many times. use the search feature or sift through back pages of pulling forum. lots of info here

i am building one with H farmall rods, bored sleeves and chevy pistons on a stroked crank. all my info and help came from here through forum members

Edited by CAL(KS) - 16 Oct 2013 at 5:55pm

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

olderironguy

Bronze Level

Joined: 16 Oct 2013

Location: missouri

Points: 7

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2013 at 9:56pm Posted: 16 Oct 2013 at 9:56pm |

ok thank you I will do some digging. Brand new to this sight sorry about digin up a dead horse so to speak.

|

|

olderironguy

Bronze Level

Joined: 16 Oct 2013

Location: missouri

Points: 7

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 12:26am Posted: 17 Oct 2013 at 12:26am |

|

Ok I have done a lot of reading and I think I am worse off than I was. All I can seam to find is a bunch of online fighting. I am an allis chalmers collector that is in search of an engine recipe for either my 1935 WC that has a wd45 engine in it already, or a stock 1951 wd that is currently stuck so needs engine work anyway. I am wanting to build both at some point but I think the WD will be first since the WC is an ok puller already.

I am looking into the WD block with a WD45 crank stroked, Farmall H rods, Chevy 400 pistons and some sort of a cam. But that being said I have never tried a performance build on a tractor so I am looking for input from those who have. I have no idea how that combination can come together or if it can.

Any help would be greatly appreciated

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 4666

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 4:40am Posted: 17 Oct 2013 at 4:40am |

I'm, basically, doing the same thing you are planning. I'm still working on the rest of my WF, but I have been talking to Marty (who goes by wi50 on this forum). I am going as finances and time allow, but I am considering either: 1. installing a stroker crank with Farmall rods and pistons for a Chevy or 2. installing a crank from a 226 with the longer stroke and installing pistons from a 170. I would advise you to read some of wi50's and some of the other engine builder's posts. You might want to start with this post from a while back: http://www.allischalmers.com/forum/forum_posts.asp?TID=71780&KW=wi50&PID=564220&title=engines-for-sale#564220

|

|

Glockhead SWMI

Orange Level

Joined: 12 Sep 2009

Location: South West Mich

Points: 2657

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 8:01am Posted: 17 Oct 2013 at 8:01am |

|

wi50 had some rotating assemblies for sale recently. Proven combos that are winning pulls. I'm sure him and a couple of the other experienced builders will pop up soon.

Welcome to the forum.

|

|

WildBill

Silver Level

Joined: 26 Aug 2012

Location: Mandan,ND

Points: 190

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 8:43am Posted: 17 Oct 2013 at 8:43am |

Just PM Marty and he will respond ..... He has the tools of the trade and will have a competitive engine for you.

good luck to ya !!!  |

|

Allis fan for life ! B,C,2-WC'S,WD45G,D19G,190xt ,LLSS 8010, terra tiger refurbished

|

|

wi50

Orange Level

Joined: 24 Sep 2010

Location: weegieland

Points: 1010

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 12:08pm Posted: 17 Oct 2013 at 12:08pm |

You need to figure out what you want and what you want to spend. None of it is to cheap, and it only ever costs the difference to do something else. That said, Farmall H rods work well, I have some Herculees rods that work well. But do you stroke to XXX or XXX and go with a billet rod, there it's only the difference in the price of the rod, the crank work costs the same. Or do you just stroke your crank, use some of the parts you already have over again and build something?

Do you run a replacement sleeve and use it as is? Bore it slightly to use an automotive piston? Or put in larger sleeves....again it only costs the difference.

None of it will really matter when you spend all your money boreing and stroking a shortblock assembly and are to cheap to put good rods in it and they fold up, or are to cheap to spend money on the induction package to feed the engine. I see to many fella's think that they need this huge engine and then don't realize that it needs air to run.

People call all the time and want to build something but lets face it, add it up and it'll be more than you think. You're thinking CHEAP and you want to swap parts around and use the Farmall rods, let me lay this out for you

Farmall rods, $100 for core rods at the salvage yard

$300 for me to put them on the turn table, clearance them, grind them, clean up the edges, tap the boltholes out, countersink capscrews for rod bolts to clear, grind them, make bushings, balance and size both ends. You have no idea how much time this takes, if it's not worth $300 then try it yourself  I spend many hours per rod by the time it's all done to make them fit. I keep saying that I'll never do any more sets because they take to much time and the billet rods are so easy.

You could use another rod, then buy a custom piston.... the rods are cheap in the end with off the shelf pistons.

Crank stroke $850, balance $75

Block line bore $150

cam grind $200

New cam bearings, rod bearings, main bearings, gasket set....$300

Set of pistons, sleeves, boreing, honeing, new rings, $400

So your cheap motor just turned into what? About $2300 or so give or take.

But it's not going to matter if you spent $500 or $5000, your head is still in need of some serious work. I've spent enough time on the flowbench and luckly I can use some cheap and common parts when putting different valves and springs in the head, but I've still got to buy parts, cut seats, install different exhaust seats, mill flat, spend many hours with a die grinder and a carbide grinding and porting, sanding and then touching up the seats when finished, cut the valves correctly and clean up and assemble. It takes $600 (with a good share of that in raw out of pocket expense) to fix up a head decent, at that I really don't make enough $$ at it to even want to do it, lucky I do enough of them that it goes fast.

Now everyone wants a carbuerator, so find a core, clean it up, swap linkage to work for the Allis, bore, make custom venturi, deo epoxy work to improve airflow. You're looking at a $350 piece when it's massaged into a finished product. Or you can clean up your old TSX464 and try, but it'll flow about half the air you need and you can give up most of your power.

Manifold, I get to machine a new neck and flange out, cut the old manifold apart, weld, grind, put it in the mill and surface it off, cut holes in the back side to allow me to get inside and port it correctly, it doesn't take long to spend many hours of time, if I sell one it's $200 to do the work.

You want a set of Murphys roller rockers? Last I checked you're looking at a little over $400 to have a set.

Put electronic ignition on, new cap and rotor, good set of plug wires, another $150 give or take.

So another $1700 gone

Yep a cheap motor takes $4000 to put togather by the time it's "turn key". It only costs another $2000 total to build a verry large engine. Billet rods run about $900($500 more than junkyard rods), boreing the block, large sleeves, boreing the sleeves, power hone, large pistons (there's many stocked parts that work well) and the rest of the costs are about the same, different parts but it really doesn't matter.

Or you can spend a little money on the head yourself, spend a little time on the manifold, put some WD pistons on stock rods with a WD45 crank, put it in low gear and have some fun for $500.

The problem is weather I build a 295 cid engine or one over 400 cid I alwayse end up with more parts, to sell those parts I have to build another engine as people just don't seam to want to do anything themselves or have any local shops that can do the specialized work to make things fit. So I've got lots of cheap parts on the shelf, different combinations. I'd love to sell parts for someone who wants to work a little bit on their own and build something. So I've got billet rods, 6" stroke crank, Farmall rods, Herculees rods, 4.6 bore pistons, 4.155 bore and sleeves, 4.28 bore parts on hand. But everyone wants something different or has a different set of rules and mostly a different budget.

I built my engine for the WD45 on the cheap.

Free early D-17 engine

$150 line bore

I made sleeves from junk

$200 or so to bore the sleeves and deck the block

I did the head for $400 out of pocket expenses for a verry nice head with re-fabricated intake ports that will flow about 50% more air than a regular ported head. It takes a lot of time.

Custom pistons from Diamons, gas ported, light, custom dish design, Total Seal gapless rings $750 for 4 pistons

Billet rods, $175 for materials, $600 in the CNC time, bushings, hardware, sizeing and honeing blow about another $125 or so...$900

$850 labor for a 6" stroke crank

I balanced the parts, no cost, I ported the head, no cost, I took the time to make everything fit and clearance it, again no cost out of pocket anyway. I still add up $3250 in expensis and I have not given myself anything for my time, shop supplies, running around and I haven't put a manifold, carbuerator or rocker arms, ignition or camshaft in it yet. Those parts are laying around here but add up pretty quick. I priced it the other day to someone adding some for the core engine value, core parts value, cam, and makeing the sleeves...It got to expensive in a hurry.

Edited by wi50 - 17 Oct 2013 at 12:25pm

|

|

"see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet"

|

|

blue924.9

Orange Level

Joined: 22 Mar 2013

Location: George Iowa

Points: 1086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 3:01pm Posted: 17 Oct 2013 at 3:01pm |

there is no thing called "cheap" in pulling, its simple less expensive, or more expensive

Edited by blue924.9 - 17 Oct 2013 at 3:01pm

|

|

jpankey

Silver Level

Joined: 12 Sep 2009

Points: 64

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 8:23pm Posted: 17 Oct 2013 at 8:23pm |

|

cheap 392 ci build $8500 turn key 440 cubic inch build 12 grand.

with a air density of .0719 and a wc motor load rpm of 1300 a 140 hp is reality at the pto.

Edited by jpankey - 17 Oct 2013 at 8:42pm

|

|

O.P.S. Heads

Orange Level Access

Joined: 02 Jan 2013

Location: Iowa

Points: 574

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2013 at 8:51pm Posted: 17 Oct 2013 at 8:51pm |

|

Density being the key word. $12000.00 is $3000.00 per cylinder by my math. Seems a little high. Being near $100.00 per HP seems a little high also.

Edited by O.P.S. Heads - 17 Oct 2013 at 9:02pm

|

|

cotncrzy

Orange Level

Joined: 07 Oct 2009

Location: TENNESSEE

Points: 599

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Oct 2013 at 6:57am Posted: 18 Oct 2013 at 6:57am |

|

Cheap = always wanting more.... I started on a tight budget, done some custom work last summer, and invested that money in a E gleaner motor, aka, D-17 engine. Built it with custom pistons, didn't know about the 170 pistons making the compression they would at the time. I used the combine carb. with some mods, I had a friend work the head, I know there were valves put in buit don't know what. I finally added a custom cam, had around 1200 bucks in it. I put the 16.9x34 full cut tires on and it would power out in the 4250 every time and on any track. In the 3500, 3750 it worked perfect. Those classes around here are fading out, without competition it's no fun. I want to move up. I need more motor... Always wanting more.... I suggest you do this build once, as you can, it will be worth it.

|

|

C, WD45,WD puller, 185, 200, 7060 Red Belly, 7060 Black Belly,8010, and a R52 Gleaner, AND PROUD OF THEM!

|

|

cotncrzy

Orange Level

Joined: 07 Oct 2009

Location: TENNESSEE

Points: 599

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Oct 2013 at 7:07am Posted: 18 Oct 2013 at 7:07am |

I would ask what class but it dont seem to matter. The D-17 engine was used for a replacement engine for those tractors running the G201 ang G226. If you are going to run "farm stock" and stay with 13.6x28 or 14.9x28, the build I described will wear you out adding weight. You do the custom carb and manifold work wi describes and you will really like it. If you are not pulling pure farm stock, better build a tough one....

|

|

C, WD45,WD puller, 185, 200, 7060 Red Belly, 7060 Black Belly,8010, and a R52 Gleaner, AND PROUD OF THEM!

|

|

WildBill

Silver Level

Joined: 26 Aug 2012

Location: Mandan,ND

Points: 190

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Oct 2013 at 8:23am Posted: 18 Oct 2013 at 8:23am |

LOL!!!! i was thinking on hiring a guy to throw weights !  I have done lots of motorsports over the years and I can say tractor pulling is a drug of its own . i will never regret pulling like I do circle track racing...damn waste of time,money,gas!!

|

|

Allis fan for life ! B,C,2-WC'S,WD45G,D19G,190xt ,LLSS 8010, terra tiger refurbished

|

|

wi50

Orange Level

Joined: 24 Sep 2010

Location: weegieland

Points: 1010

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Oct 2013 at 1:01pm Posted: 18 Oct 2013 at 1:01pm |

I used to pull an outlaw WC. I could turn the engine up to 6500 RPM, there's video of it on Youtube, a few runs from the first one to several later as I got it tuned. I had around $1500 in the whole engine. Not $12,000, just the bare necessities with nothing but a will to learn all I could about machining and engines at the time, over the winters of 2002-2004.

It cost me $100 for a friend to offset grind the crank. I wasn't about to thow some welded stroker in it, there were better places for the money.

I bought some new unwanted pistons off Ebay for $110 for a set of 10 forged Venolia pistons, I had to buy decent rings after that.

Cam cost me $100 to have a friend grind....he really had no idea if it would work, neither did I but the numbers made sense.

Another friend bored the block for free, I made the sleeves from Case ones from the dumpster.

I found some rods laying on a pallet, didn't know what they were but I got free rods and figured out what they were from. They just looked like they woule fit and with some machine work I made them fit.

I built the bottom end, billet main caps, rails, cross bolted everything togather and made a billet timeing cover, about $250 in materials. I had it line bored and my friend at the shop just scratched his head and said this is cool $#@!, how's $100 sound.

I used a $20 junk HEI distributer and some new parts to build an ignition system, I bought a cheap SBC fluid dampner and machined the front of the crank.

Bought some materials and a friend of mine wanted to learn machining, we stood at the Bridgeport and made a set of billet roller rockers for about $50 worth of supplies.

A few more simple parts, free junk from the dumpster behind a local implement dealership, free junk from other friends and more raw materials.

I spent a few hundred bucks on materials to build a tuned header and intake manifold. I made my own twin disc clutch. Plumbing supplies, a leftover small radiator. I used some secondhand parts in the cylinder head because it was a total butcher job and I didn't give it much of a life expectancy. I ran some water in the head, none in the block. I had that thing so strapped and welded every which way to keep it from tearing apart that I just filled it with hardblock. A few times it took a pretty good hit of NOS, there's a few pulls around that have no rules. No one can read or write, no rules = no problems.

I ran that engine for several years with a lot of success in the outlaw type classes around here. Nothing is impossiable, but some things take a lot of time.

It really depends on how hard you want to work and how much you are willing to learn how to do yourself.

Edited by wi50 - 18 Oct 2013 at 1:10pm

|

|

"see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet"

|

|

olderironguy

Bronze Level

Joined: 16 Oct 2013

Location: missouri

Points: 7

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Oct 2013 at 7:54pm Posted: 18 Oct 2013 at 7:54pm |

|

Ok I thank everyone for responding to my question. I guess more to the point instead of using the word cheap, budget minded might be more appropriate. For example stroking a crank for a WD vs. using a WD45 crank if that makes a difference. Cost vs. return is more of a concern than overall price.

This will be a long term project, but I am trying to build a game plan so I know what parts to gather for the build.

In one of the responses to my post I read that 170 pistons can be used on a WD45 crank. What are the pros and cons to that.

I have restored several Allis Chalmers tractors and have several more in the waiting room so to speak. My thought is to build a farm stock puller and work up into the open class. So that being said for now I think I would be better off starting with a mild build maybe just improving on what Allis themselves did.

|

|

olderironguy

Bronze Level

Joined: 16 Oct 2013

Location: missouri

Points: 7

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Oct 2013 at 8:11pm Posted: 18 Oct 2013 at 8:11pm |

|

As for the WC with the WD45 engine I am going to try to tune it a little to get a bit more out of it. I do ask for everyone's patience as I have no idea what I am doing when it comes to performance in a tractor engine.

Making stock look and run good again I can do, but performance I am lost with.

|

|

Just remember the Ark was built by amateurs, and the Titanic was built by professionals

|

|

wi50

Orange Level

Joined: 24 Sep 2010

Location: weegieland

Points: 1010

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Oct 2013 at 10:50am Posted: 19 Oct 2013 at 10:50am |

Cost vs return, sometimes I use a D-17 crankshaft which is 4.5" stroke, I typically have them welded to 6" stroke and run a billet rod which makes assembly a breeze. There's further to go but it's at the sacrafice of rod angle which is important. I use a small block Chevy 2" crankpin diameter, 1.985" (if my memory is correct anyway). So for all practical purposes I'm takeing a 4.5" stroke crank with a 2.375" crankpin, welding it out and re grinding for a 6" stroke with a 2" crankpin. Lets see, I'm adding 1.5" stroke and grinding way into the original crankpin going with a small diameter crankpin, there isn't much left of the original crankpin when it's done.

The work costs the same, the welding is a small part of the work involved in stroking a crankshaft. There's welding, straightning, indexing and grinding in a rough journal. Then another trip in the welder, more straightning, indexing and grinding. Then it's time for a finish grind on all the crankpins.

What I'm getting at is when I put togather a 5.4" or 5.5" stroke engine with the Farmall rods and Chevy pistons, there's no reason you can't use your valueless 4" stroke WC pr WD crank. It's going to cost the same amount of money to use it as the 4.5" stroke WD45 crank. In these early blocks you start to run out of room with the larger Farmall rod at 5.5" stroke it takes quite a bit of work on the rod to get it to clear. You actually have MORE parent metal left in that (original 4") crank with the 2.25" crankpin used by the Farmall rod when useing a 4" stroke crank welded out to 5.4" stroke than you do when you use a 4.5" stroke crank and go out to 6" stroke which is verry common. On these smaller bore, easy to assemble engines like you are thinking of with the slightly overbored sleeves, Farmall rods and Chevy pistons there is absolutly no reason you can't use your 4" stroke crank as a core to start with. You'll have your WD45 one left for future use or sale. I don't know about the rest of the country but I have a stack of 4" stroke WC and WD crankshafts that are worth their weight in scrap, where the WD45 ones are getting hard to find good cores and expensive to buy. There's high compression engines with big bores makeing way more power on a weaker crankshaft than what I just outlined above.

|

|

"see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet"

|

|

wi50

Orange Level

Joined: 24 Sep 2010

Location: weegieland

Points: 1010

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Oct 2013 at 11:15am Posted: 19 Oct 2013 at 11:15am |

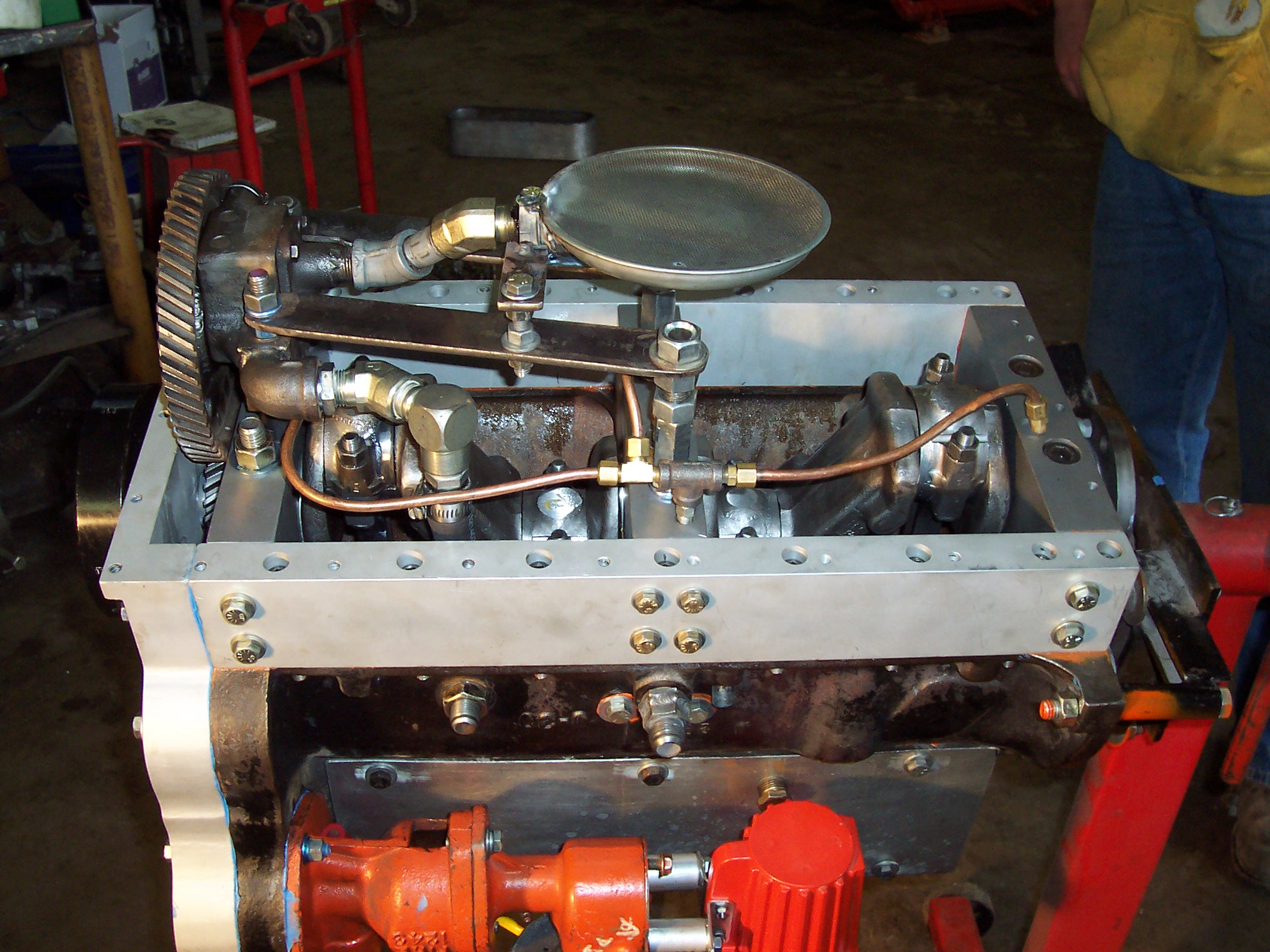

I'm putting togather an engine for an unstyled WC restoration project, and maybe something to take to the fair and threashing bee. I didn't want to spend much money on the engine, I'm not trying to make any big power, and I didn't have any stock type parts laying around that were any good from other parted out engines that I could simply bolt togather.

I made a set of sleeves for it from a John Deere, made them to fit tight in the block and press fit into the bottom counterbore, with a little sleeve retainer there's no chance of leaking water, I put about an inch of fiber block filler in the bottom. The bad part is I can't replace them without boreing, but I'm guessing it will never wear out getting driven from one shed into the other and a trip to the fair once in a while.

I had a leftover half set of pistons, some new Sealed Power hyperutectic pistons from a BBC that were 4.28" bore and half a set of cheap rings left from another engine I put togather for someone.

I found some Cockshutt rods, Herculees diesel engine, 2" crankpin and the rods are 8" center to center length.

I had an otherwise junk WD45 crankshaft that wasn't something I wanted to use, but with the smaller crankpin diameter of the Herculees rod I can offset grind the crank to 4.85" stroke and make things useable again.

It just worked out that a few hundred bucks worth of machine work to the crank, many hours of my time makeing custom bushings for the rods, makeing sleeves, boreing and honeing, I just don't have much money in a 280 cid shortblock. I've got more time in cleaning up old parts, blast cabinet time and messing around than anything.

I had a John Deere 202 diesel head that was junk but had good valves in it. These valves are larger than the Allis valves, but not to large, the right length and it doesn't take much to make them fit. Some head work, new exhaust seats and some nice valve, seat and bowl work and it's a pretty good match for my engine.

It all works out for a lower compression ration of about 8.5 to 1, I just wanted something that has decent power, runs on regular pump gas, doesn't cost much or take much work to put togather that I can go plow a few rounds with untill I realize that the invention of 12 volt lights on the tractor was a much bigger improvement than haveing autosteer.... and I've got less in the whole tractor than one autosteer activation to Deere.

|

|

"see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet"

|

|

jpankey

Silver Level

Joined: 12 Sep 2009

Points: 64

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Oct 2013 at 11:49am Posted: 19 Oct 2013 at 11:49am |

|

Mlpankey owning interest in a couple of machine shops gets to see many different ways the industry attaches sleeves into blocks , jugs etc. His adoption of fastening a sleeve into the 226 block from the motorcycle industry has really opened up the bore size boundary limitations with knowledge of the leroi air compressor that's a 226 inch front four cylinder and the back two cylinders having 5 inch pistons has made his machine shop capable of installing the largest bore known among 226 allis builders with easily removed sleeves so that the owners have the option of refurbishing that special grown favorite block pullers hate to loose.

|

|

Ihateillinoisnazis

Orange Level

Joined: 15 Jan 2013

Location: By The Lake

Points: 273

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2013 at 7:33am Posted: 21 Oct 2013 at 7:33am |

jpankey wrote: jpankey wrote:

Mlpankey owning interest in a couple of machine shops gets to see many different ways the industry attaches sleeves into blocks , jugs etc. His adoption of fastening a sleeve into the 226 block from the motorcycle industry has really opened up the bore size boundary limitations with knowledge of the leroi air compressor that's a 226 inch front four cylinder and the back two cylinders having 5 inch pistons has made his machine shop capable of installing the largest bore known among 226 allis builders with easily removed sleeves so that the owners have the option of refurbishing that special grown favorite block pullers hate to loose. |

The ramblings of a bumbling idiot continue.... Go home troll. Where's the Gleason?

|

|

THE-MAN

Silver Level

Joined: 11 Mar 2013

Location: By the lake

Points: 156

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2013 at 9:19am Posted: 21 Oct 2013 at 9:19am |

|

Frappe' !? Did that even begin to make sense to you? I bet he sounds the same way when hes drunk..

|

|

Juiceman

Silver Level

Joined: 26 Aug 2013

Location: West Virginia

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2013 at 8:19pm Posted: 21 Oct 2013 at 8:19pm |

|

Hi guys. Ive read through the posts and now know round about what kind of cash its going to take to get the power i want. I was wondering what kind of hp i really need to pull the 4500 with the diesel ring and pinion. The tractor is stock with the origonal rear end in it now. We have a pretty nice set of top cut 15.5 38's on it now and powered out in the 4000 and 4500 last pull at around 250 feet both times. Thinking if we could get to around 60hp that should be enough, but not for sure and was wondering what some of you veterans know that i don't. Thanks

|

|

mattb

Orange Level

Joined: 11 Jan 2011

Points: 348

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Oct 2013 at 8:04am Posted: 22 Oct 2013 at 8:04am |

|

I have the a wd with a diesel rear end e motor with 4.125 flattops never power out in 4500 on s il clay. Have pulled 5000 several times over 6 years never powered out in there either

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

jpankey wrote:

jpankey wrote: