| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2019 at 3:24pm Posted: 17 Oct 2019 at 3:24pm |

|

The thicker you make the head gasket, the harder it will be to hold. Same as a 1/4" one-wire hydraulic hose versus a 1/2" one-wire hyd hose. The smaller hose will tolerate a lot more pressure before it fails. Cut your piston tops down.

|

|

|

Sponsored Links

|

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2019 at 6:41pm Posted: 17 Oct 2019 at 6:41pm |

|

The gasket will be .155" does that seem workable ?

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Oct 2019 at 9:53pm Posted: 25 Oct 2019 at 9:53pm |

|

Suggestions on where to get a Allis 175 gas cam grind done on a G262 ?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2019 at 4:43pm Posted: 26 Oct 2019 at 4:43pm |

|

30 or more years ago, I sent a 175 cam to Berry Cam Lester Prairie, Minnesota for them to copy. I had them do probably a dozen regrinds for me over the years. I understand they are under different ownership now, and have heard maybe they aren't as dependable as they used to be.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2019 at 6:36pm Posted: 26 Oct 2019 at 6:36pm |

|

Thanks Dr Allis, I will see if I can find a shop with better review.

|

|

Robacpuller

Silver Level

Joined: 07 Apr 2016

Location: Wisconsin

Points: 248

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Oct 2019 at 7:12pm Posted: 27 Oct 2019 at 7:12pm |

|

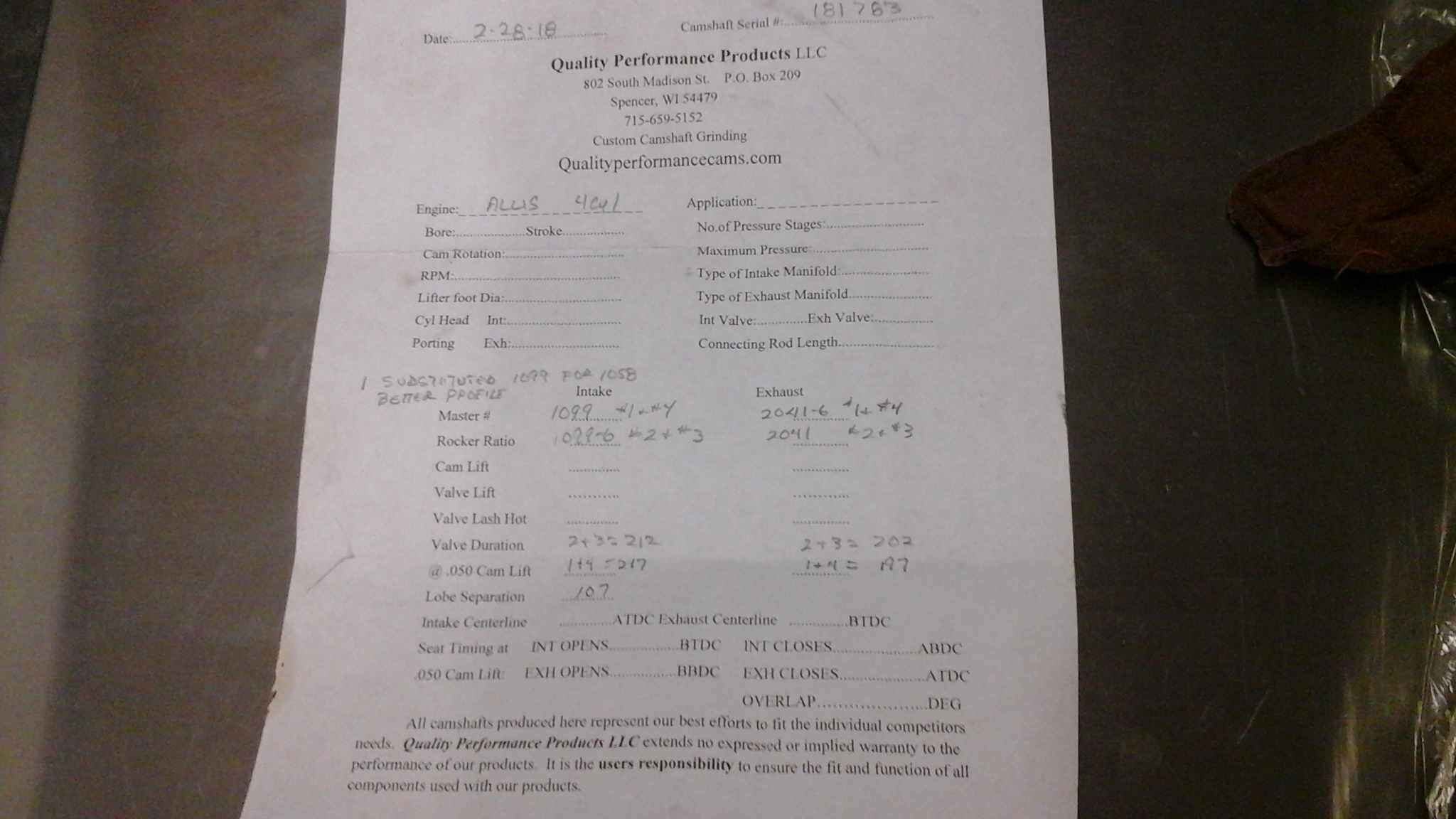

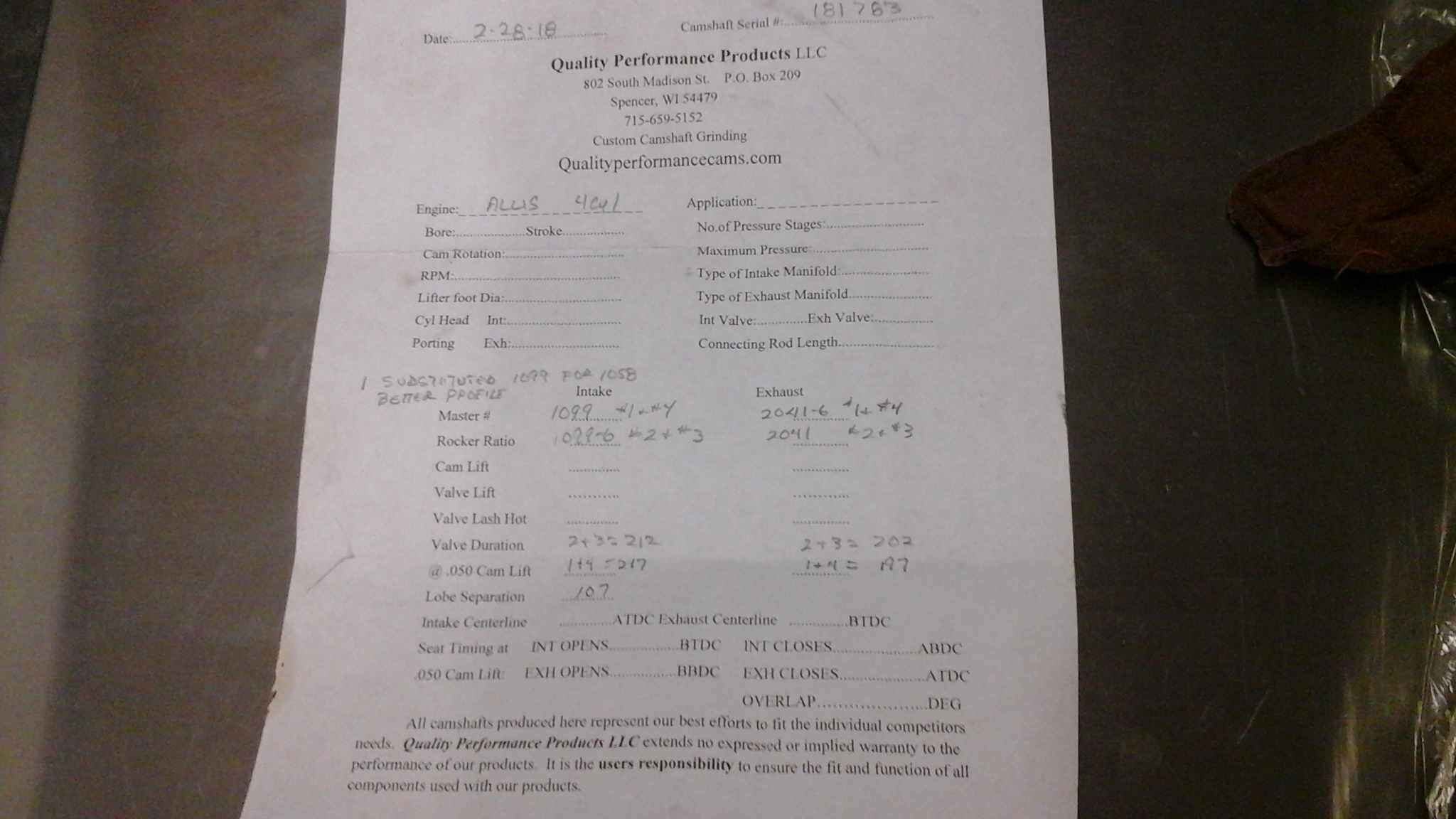

Quality performance products in Spencer Wi.

ph. Number 715 659 5152.

They did a 4 master grind on my D17 cam. Wi 50 does a lot with them.

Give me a P.M. or ur cell number. I will give u a copy of my cam card.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Oct 2019 at 8:50pm Posted: 27 Oct 2019 at 8:50pm |

|

Thanks Robacpuller,do they have a good return on finished product time line? Do they do head work on AC G262 ?

|

|

Robacpuller

Silver Level

Joined: 07 Apr 2016

Location: Wisconsin

Points: 248

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Oct 2019 at 9:00pm Posted: 27 Oct 2019 at 9:00pm |

|

Call me at 608 228 4843.

I can fill u in.

|

|

Robacpuller

Silver Level

Joined: 07 Apr 2016

Location: Wisconsin

Points: 248

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2019 at 8:44pm Posted: 28 Oct 2019 at 8:44pm |

I can't get my text to go through. I am posting it here.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 10:44am Posted: 10 Nov 2019 at 10:44am |

|

If I have a allis G262 stock bore flat top pistons, 0.195" from top of piston to top of head,0.175" head gasket, 3.75"bore head gasket what would the compression ratio be?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 5:16pm Posted: 10 Nov 2019 at 5:16pm |

|

11.67 to 1 with no valve protrusion.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 5:49pm Posted: 10 Nov 2019 at 5:49pm |

|

Thanks DrAllis ,I am wondering with that setup how is it possible to start the engine with a snowmobile battery that has 320 CCA ?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 7:06pm Posted: 10 Nov 2019 at 7:06pm |

|

You won't. If that is all you can have for weight, you'll need a jump pack to get it started and disconnect it afterwards. You'll get tired of that after a couple of seasons and get a real battery in it.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 7:48pm Posted: 10 Nov 2019 at 7:48pm |

|

We had 700 CCA battery and a 320 CCA we would start it then remove the 700 CCA battery used the 320 battery for our ignition, I stalled it on a pull and restarted with just the 320 battery and that was with the setup with 11.67 to 1.

|

|

brad durst

Bronze Level

Joined: 20 Aug 2018

Location: richland center

Points: 85

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 7:54pm Posted: 10 Nov 2019 at 7:54pm |

|

i have a good running gas 190 engine for sale. its complete 800$ the fan to the pressher plate

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2019 at 8:06pm Posted: 10 Nov 2019 at 8:06pm |

|

Sorry not interested in the 190 engine.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2019 at 7:34pm Posted: 13 Nov 2019 at 7:34pm |

|

Was thinking someone would have an answer how it was possible to start the motor with 320 CCA battery with 11.67 to 1 compression,I am refreshing the motor now so if I did something incorrect before I would like to fix it.

|

|

steve fischer

Orange Level

Joined: 11 Jul 2011

Location: sleepy eye mn

Points: 971

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Nov 2019 at 10:38pm Posted: 20 Nov 2019 at 10:38pm |

|

berry cam has two different grinds one is allis number 175 (very hot )the one you want is the model 175 gas grind

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Nov 2019 at 11:35pm Posted: 21 Nov 2019 at 11:35pm |

|

Thanks for cam info. Mr Fischer

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2019 at 7:18am Posted: 27 Nov 2019 at 7:18am |

|

Why haven't you ran a cranking compression test on this engine??? You should have 240 psi or more, with the throttle wide open, all spark plugs removed and a battery charger on the battery to keep cranking speed fast and consistent.

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2019 at 7:50pm Posted: 27 Nov 2019 at 7:50pm |

|

I have taken the engine apart and will be doing the stuff to it that you talked about and see what results I will get and yes I should done some more testing.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2019 at 6:06am Posted: 28 Nov 2019 at 6:06am |

|

What exactly did you have your ignition timing set at and what octane of gas were you using ?? With 12 to 1 compression, it will require the timing to be LESS than the OEM timing of 25 degrees BTDC @ 2,000 RPM. More like 18 to 20 degrees BTDC and really should be done on a dyno of some type to achieve max power output. Octane rating needs to be 110 or better for best results.

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3297

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2019 at 10:55am Posted: 28 Nov 2019 at 10:55am |

high compression engines are for high rpms - not 1800 rpm luggers. the peak cylinder pressure , unless controlled with octane and timing - as Doc sez on a dyno - will not be kind to internal components .

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2019 at 9:09pm Posted: 28 Nov 2019 at 9:09pm |

|

I was running 114 then 110 octane gas,do not have pto for dyno and running 3000 rpm maybe not a lugger.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20525

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2019 at 6:06am Posted: 29 Nov 2019 at 6:06am |

|

And what was the timing set at ?????

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2019 at 6:12pm Posted: 29 Nov 2019 at 6:12pm |

|

I do not remember Dr Allis.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8241

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2020 at 1:44pm Posted: 06 Jan 2020 at 1:44pm |

|

We had a 261 Chevy (big brother to 235) and was notorious for cracking pistons when run above 3000 rpm. Don't know if 235 piston is stronger but you may be asking for trouble.Just saying....

|

|

Fullpull

Bronze Level Access

Joined: 02 Jun 2019

Location: Canada

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2020 at 7:22pm Posted: 06 Jan 2020 at 7:22pm |

|

The rpm will be 3000 max. We ran the other setup for 5-6 years at 3000 rpm and pistons look fine.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)