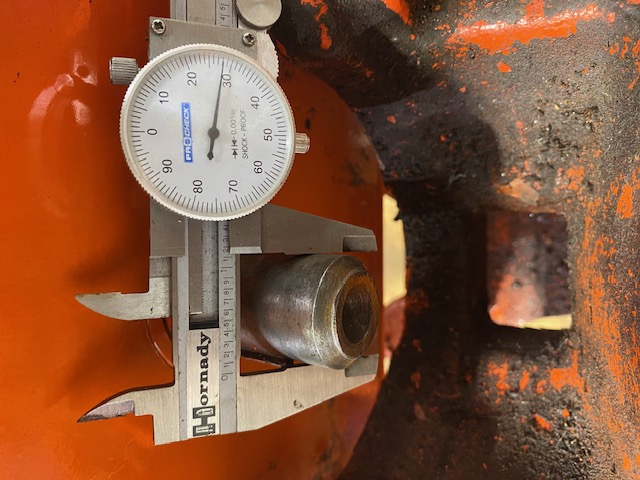

The pulleys on the BE/CE and all the small D series engines are a FRIM press fit. Unlike the 201/226 engines that have a tapered bolt to lock the pulley to the crank, the "small block" engines rely on a tight fit to keep them in place as the small set screw only locks against the key, not into a tapered hole in the crank.

This is why so many of the "small block" pulleys are cracked or broken by uninformed persons using a jaw puller without backup to remove them and also not removing the sometimes second set screw.

The same goes for reinstalling them, just wacking them on cold is a sure way to destroy the "small block" pulleys, Heating them slightly and LIGHT force with a piece of soft metal against the pulley is the way to safely put the pulley back on.

If the pulley slides on easily when cold, it will surely come loose.

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)