| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: AC 175XTD is SOLD !! Topic: AC 175XTD is SOLD !!

Posted: 03 Sep 2023 at 7:11pm |

Edited by DrAllis - 01 Oct 2024 at 7:14pm

|

|

|

Sponsored Links

|

|

|

captaindana

Orange Level

Joined: 14 Sep 2009

Location: Fort Plain, NY

Points: 2558

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2023 at 7:35pm Posted: 03 Sep 2023 at 7:35pm |

|

Can’t wait to hear….!

|

|

Blue Skies and Tail Winds

Dana

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2023 at 7:52pm Posted: 03 Sep 2023 at 7:52pm |

|

The plan is to transplant this 95 flywheel HP Gleaner 4 cylinder 433-TI turbocharged engine into this 1974 model 175 gas chassis. It will have a new 12 inch foot clutch from a 100+ HP 7000 tractor. Injection pump will be freshened up. Brakes will be new. Seat suspension will be reconditioned and new seat cushions installed. This will make someone a pretty nice 67 HP (at 540 PTO speed) or 83 HP (at full throttle) modern and fuel efficient tractor. Hope to be done by early Spring. Stay tuned. Will be for sale as soon as it is completed. Thanks for watching.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7489

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2023 at 8:12pm Posted: 03 Sep 2023 at 8:12pm |

|

Awesome! That will really wake up that 175! How are you going to run the hydraulic pump? That tractor has the front pump. Should be interesting to see!

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2023 at 8:22pm Posted: 03 Sep 2023 at 8:22pm |

|

Front hydraulic pump under the radiator, yes. Just have to drill four holes in the crankshaft pulley to use the adapter from the gas engine. And, maybe the holes will already be there. Haven't got that far yet.

|

|

Don Jr NY

Silver Level

Joined: 11 Sep 2009

Location: Waterloo NY

Points: 357

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 4:59am Posted: 04 Sep 2023 at 4:59am |

|

Hi Doc. I always wondered why they didn't do this instead of using the perkins engines in the 170 and 175 tractors. I'm not trying to be a pessamist or anything but shouldn't you use a 170 chassis instead of a 175? I only ask this because the 175 is the last gas model they built and according to Norm's bible there were only about 1009 gas models made. I would think that would make it a more collectable model than a 170 would be. I would like to add one to my collection someday but here on the east coast they seem to be scarce. Just my humble opinion and not meant as any criticism toward your project. Don Jr.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4057

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 5:23am Posted: 04 Sep 2023 at 5:23am |

|

Friend of mine has a D-17 with the 433 TI in it. Runs good! He also has a Farmall M with the same engine.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 7:01am Posted: 04 Sep 2023 at 7:01am |

|

Finding any 170 or 175 seems to be a challenge these days, and for a reasonable price makes it even more difficult. This particular tractor badly needs an engine overhaul, so instead of spending $$$$ rebuilding the gas engine, why not resurrect it with a turbo-diesel transplant ? Also, to do an early 170/175 with the side hydraulic pump simply cannot be done, or if you got it done it wouldn't be nice. The power steering ram along the right front corner of the engine is in the way. The Perkins engine is shorter than the Allis engine making it possible. Also, the 175 tractors have 180/185 final drives, making it more rugged in the rear end if it gets used more heavily. Several reasons to use this tractor and the diesel engine install won't be a butcher job. It will look like it maybe could have been factory. The Harvey engine division had this 4 cylinder engine since 1964 (non-turbo) when they came out with the One-Ninety and in 1965 with the XT. Problem was, they never considered using a turbocharger on it until the late 1970's with the 78 model K2/F2 Gleaner combines. Without a turbo it was only 50 flywheel HP. Harvey needed to have 63 to 73 flywheel HP for a 170/175 tractor and without a turbo, that means 230 to 250 cubic inches instead of 200 cubes. They didn't allow for that many cubes in the engines design platform.

|

|

Tom59

Bronze Level

Joined: 27 Feb 2021

Location: Lebanon Tenness

Points: 155

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 8:12am Posted: 04 Sep 2023 at 8:12am |

|

Thanks for sharing your AC 175 tractor engine swap project. Look forward seeing it completed and pictures. Interesting story about the 433 engine and using a turbo on that engine to boost the horsepower, l really enjoy learning stuff like that, thanks for sharing.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4057

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 7:39am Posted: 05 Sep 2023 at 7:39am |

|

Doc, there seem to be a fair number that go through Colfax. Not too many 175 gas models but I see a diesel on the lot once in awhile and 170's seem more common.

|

|

captaindana

Orange Level

Joined: 14 Sep 2009

Location: Fort Plain, NY

Points: 2558

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 11:25am Posted: 05 Sep 2023 at 11:25am |

|

Oh man this is going to be a thriller in the making !!!

|

|

Blue Skies and Tail Winds

Dana

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1861

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2023 at 11:21am Posted: 11 Oct 2023 at 11:21am |

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2023 at 12:10pm Posted: 11 Oct 2023 at 12:10pm |

|

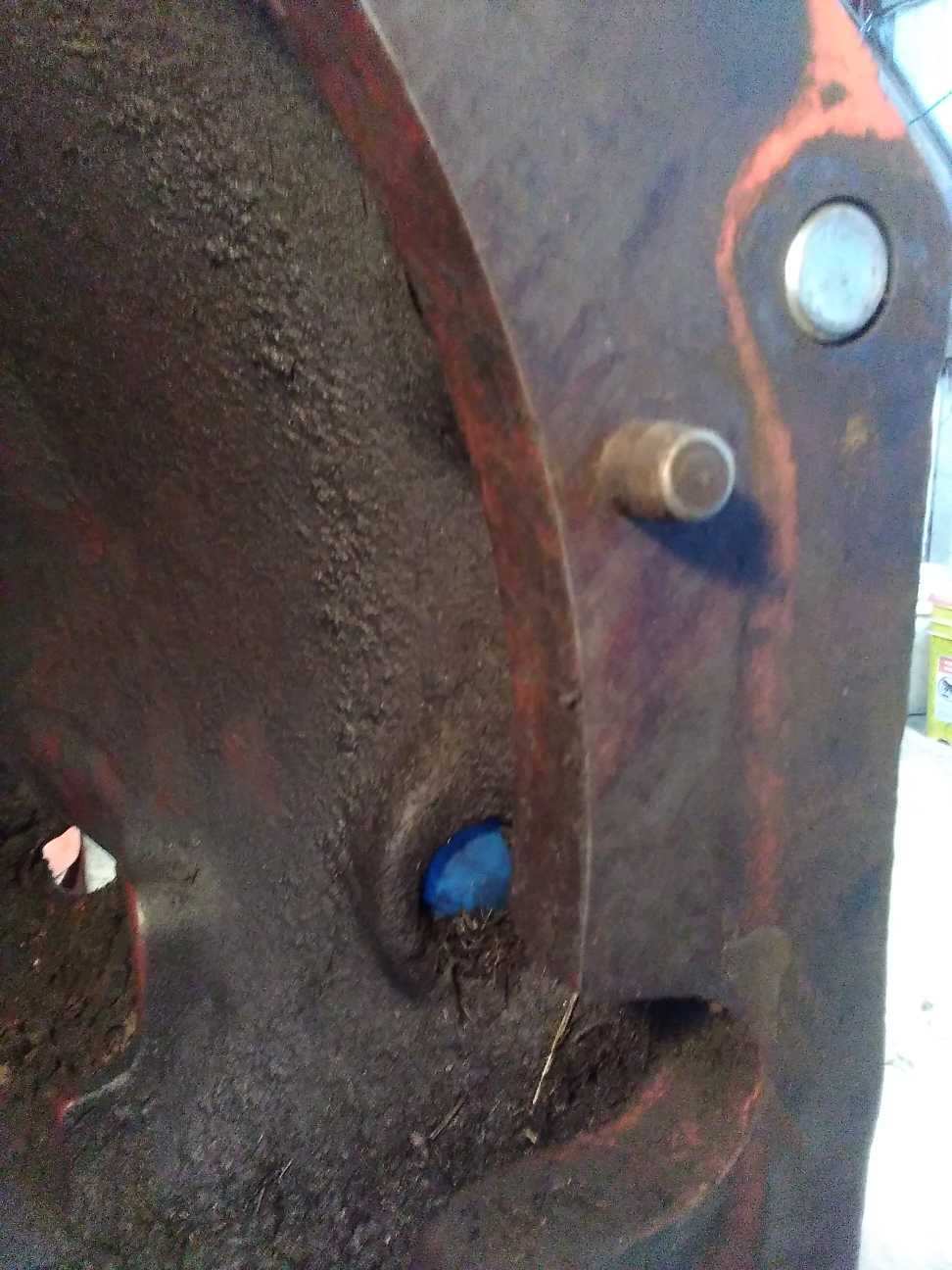

Just some recent progress pictures. I'm using a maroon 7000 flywheel, pressure plate, and clutch disc assembly, which is 12 inches in diameter, instead of the original 11 inch clutch. To make this work, I have to space the engine forward, which requires a homemade spacer plate to go in between the engines backplate and the bell housing. The actual spacer dimension needed is 1.312" to 1.375" for the clutch shaft nose to connect to the pilot bearing. I have chosen to make my own relatively inexpensive spacer, by using two 1/2" thick engine backplates, sandwiching them together, and cutting them open in the center to slip over the flywheel and then attaching them to the backplate on the engine. To do this, I had to deepen the pilot bearing pocket into the flywheel .320", and move the throw out bearing and shifter rearward one full inch. This should work fine and won't cost much as compared to a custom made 1.375" thick plate with the center removed. Pics show all this I think except the T.O. bearing rework. In the lower right corner of the bellhousing is an alignment dowel hole that is never used on a gasoline powered D-17/170/175 tractor. I made a 1/2" diameter dowel pin to go in this hole and the engine backplates are already drilled to accept this dowel pin, which insures the engine and clutch shaft will be in perfect alignment. One 1/2" hole has to be drilled/tapped to clamp the engine to the bellhousing, but that was an easy job. Hope to have the engine and clutch assembled in a couple weeks. Picture of engine with 1 inch spacers to mock up what I wanted to do. Cardboard template shows how much has to be removed to fit over the flywheel.

Edited by DrAllis - 11 Oct 2023 at 6:06pm

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3518

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2023 at 12:14pm Posted: 11 Oct 2023 at 12:14pm |

|

Thanks for sharing DrAllis & Coggonobrien. Nothing against the Perkins diesel, but IMO the AC 433 is how the One-Seventy & 175 diesels should have been built at Milwaukee's AC factory.

|

|

captaindana

Orange Level

Joined: 14 Sep 2009

Location: Fort Plain, NY

Points: 2558

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2023 at 2:16pm Posted: 11 Oct 2023 at 2:16pm |

|

Marvelous!

|

|

Blue Skies and Tail Winds

Dana

|

|

Jason n

Bronze Level

Joined: 05 Feb 2018

Location: Pa

Points: 44

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2023 at 8:34pm Posted: 11 Oct 2023 at 8:34pm |

|

Is the original 175 radiator enough to cool the extra horsepower? I suppose so being that the new motor is less cubic inches

|

|

Ted J

Orange Level

Joined: 05 Jul 2010

Location: La Crosse, WI

Points: 18943

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2023 at 11:11pm Posted: 11 Oct 2023 at 11:11pm |

Very interesting thread Doc. I'll be awaiting the next update.

|

|

"Allis-Express"

19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2023 at 5:51am Posted: 12 Oct 2023 at 5:51am |

|

As with any engine transplant that has more HP, the heat rejection capacity of the radiator could be challenged in some conditions. I intend on removing the intercooler on this engine to make things fit under the hood without modifications to the hood. This will help reduce the load on the radiator. I know in the 7000 tractor series days, the cooling systems were generally designed to maintain 100 degrees F over whatever the ambient temps of the day were. So, on a 100 degree F day, with the engine at 100% full rated load, one could expect to see 200 degrees F on the instrument panel temp gauge. I did actually dyno test my D-17 XT project tractor on an 80 to 85 degree summer day and at full load I saw 195 to 200 degrees temp at full load. That was with a clean radiator, tight fan belt and a properly positioned fan to move maximum air flow thru the radiator. I also had a Fall plow day with a 4 x 14's plow and the temps that day were in the low 40's when we started and probably near 50 degrees when we finished and had no issues whatsoever. So always remember the amibient temp makes the end result number. I'm not concerned about this 175 XTD cooling system keeping up for how the tractor should be used. I expect it to be just like the D-17 XT tractor with the same engine.

Edited by DrAllis - 12 Oct 2023 at 7:21am

|

|

acken

Bronze Level

Joined: 02 Jan 2014

Location: Minnesota

Points: 101

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2023 at 8:40pm Posted: 12 Oct 2023 at 8:40pm |

|

As usual your projects, and posts are very educational regardless of my own AC background. A few years back I spoke with an AGCO Service Tech about hydraulic oil temp concerns. He made the same comment about oil temp being acceptable at 100 degrees over ambient.

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1861

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 8:04am Posted: 13 Nov 2023 at 8:04am |

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 8:15am Posted: 13 Nov 2023 at 8:15am |

|

Engine and clutch assembly are now installed. Trying to document this as I go, so anyone who might be thinking of doing the same thing can use this information. Using two OEM engine backplates made this a very inexpensive and accurately centered installation. I can't imagine what I would have spent having this 1 inch adapter made from scratch. I had to sink the pilot bearing into the flywheel a little deeper (.320" to .325") but that cost was minimal. The throwout bearing shifter was machined .900" farther back to move the throwout bearing away from the flywheel. Both of these procedures cost me less than $100 bucks. The lower right hand alignment dowel is just a 1/2" bolt shank driven in the existing hole. One 1/2" hole was drilled and tapped 1/2" x 13 NC into the bellhousing above the starter area, so there are four 1/2" bolts securing the engine to the tractor, plus the side frame bolts. The rearmost backplate is machined so if the tractor ever needs a foot clutch, a long dowel bolt can be used on each side to hold the back of the engine up while splitting it. Anyone could make this 1 inch adapter plate. I did have access to a plasma cutter, which allowed me (in about 3 minutes) to open up the centers of each adapter plate to go over the flywheel. All three plates are bolted and stitch welded together so they can't move. Now on to the injection pump OH and turbocharger reconfiguration !!! Then, a quick fire-up without a hydraulic pump or its drive and keep moving towards the finish line. I am going to have the fuel tank narrowed up about 2 inches front to back to get everything to fit with a 1000 CCA battery in the tray.

Edited by DrAllis - 13 Nov 2023 at 8:22am

|

|

gleaner1

Silver Level

Joined: 17 Dec 2009

Points: 225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 12:03pm Posted: 13 Nov 2023 at 12:03pm |

|

A gas 175 is way too rare to be butchered up.

Heck most tractor books don’t even acknowledge there was even that model produced.

|

|

ALLIS CHALMERS "The color is orange"

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1861

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 12:20pm Posted: 13 Nov 2023 at 12:20pm |

|

Outside of the fuel tank modification, there's been nothing done that can't be undone......

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 12:34pm Posted: 13 Nov 2023 at 12:34pm |

|

The gas engine in this tractor needs to be overhauled, as it uses oil badly. That would have cost me close to 3 grand when all finished, including the foot clutch. Each to his own, but 3K spent converting to this to an A-C turbo diesel is a very good upgrade. If you've never ran one of these engines, you don't know what you're missing. A couple of gallons less in the fuel tank (under the hood) is nothing with the fuel efficiency of the diesel powerplant. The gas engine is for sale if someone wants a running gas engine that uses oil. Make me an offer.

|

|

Pat the Plumber CIL

Orange Level

Joined: 11 Sep 2009

Location: Springfield,Il

Points: 4929

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 1:41pm Posted: 13 Nov 2023 at 1:41pm |

|

Thanks for posting this project

Sometimes you have to dismantle, reconfigure something nice to make something even more special. I know there weren't a lot of these but I say carry on . Sounds like AC should have been using these engines in the 175s. Can't wait to see how it turns out.

|

|

You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails

1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 2:06pm Posted: 13 Nov 2023 at 2:06pm |

|

The only "butchering" might be a new hole in the hood for the exhaust pipe. And the only reason for that is there's a pre-cleaner stack on the right half of the hood and the OEM exhaust hole is on the left half. Makes sense to have the exhaust pipe in-line with the air cleaner stack for best visibility. I can make the exhaust come out the left side, but for now, don't think I'm going to do it that way. Nothing else is or will be butchered. The backplates to the engine are an engine part, not a chassis part. I've seen a real butcher job on a D-19 with one of these engines installed in it on the internet. It ain't pretty.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7489

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 3:54pm Posted: 13 Nov 2023 at 3:54pm |

gleaner1 wrote: gleaner1 wrote:

A gas 175 is way too rare to be butchered up.

Heck most tractor books don’t even acknowledge there was even that model produced.

|

I would not be worried about ditching the gas engine for the 433. Yes,

175 gassers are rare, but that does not make them desirable. The 433

diesel is a beautiful engine to run and can generate far more power

while using much less fuel than the 226. The 226 is my favorite gas engine and they have their place in the WD45s and D17s. But in the mid 70s, diesel was the way to go. As others have said, Allis should have used the 433 in the 175 from the get go.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3518

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 4:28pm Posted: 13 Nov 2023 at 4:28pm |

|

DrAllis, good thinking on the 3 engine plates. Thanks for sharing and please keep updating as it goes.

How’s the song go?

“Ya can’t always get what you want……..

But if ya try sometimes,,,,

ya might just get what you need…….. Ooooh ooh oooh yeah!”

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 5:46pm Posted: 13 Nov 2023 at 5:46pm |

A little more info on grafting this engine into D-17's and D-19's for anyone contemplating doing so. If the donor chassis is any D-17 diesel, or any D-19, the flywheel from the D-262 or G-262 fits the 433-T or 433-TI engine crankshaft !! So, right off the bat, you are in business with flywheel and 11 inch clutch assemblies. When it comes to D-17 gassers and all 170/175 chassis (G or D), the clutch shaft is longer, approx 1 3/8" if I remember right. I was able to fudge this number down to an inch by moving the pilot bearing forward a little and using a different clutch disc on this 175 project. In my two engine swaps (D-17 III gas and now this 175) both had the long clutch shafts, but even they were different from each other !! The Pre series 4 gas clutch shaft has more spline length, allowing the clutch disc to slide on farther, which allows the engine to be made to fit flush to the bellhousing with no spacers, which in the end, helps you with the possibility of having hydrostatic power steering. A series-4 gas or early 170/175 chassis it will be impossible to do one of these 433 engine installs because of lack of room for the OEM power steering ram at the right front corner of the engine bay. If you're OK with manual steering, then have at it. The 175 I'm using is the later chassis with the front axle external steering ram cross-ways on the tie rod. A series 4 D-17 chassis and all 170/175 chassis use the larger diameter throwout bearing. This will then require the use of a maroon 7000 12 inch clutch disc and pressure plate and a 180 thru 7000 flywheel, like I'm doing on my 175. The trouble with any series 4 gas and all 170-175's is the 1 inch minimum spacer plate will be required to make this work. This is because the clutch shaft spline depth is shallow compared to pre series 4 models. On my series 3 gasser, I used a 180-200 flywheel and 12 inch clutch assembly which uses the smaller diameter throwout bearing and also required some grinding inside the bellhousing, but not a lot. Confused ?? That's why I've done this, to try and keep my mind straight on all the nuances between the different models. The power steering thing is a bugger on some of these. I cannot imagine manual steering with such a wonderful engine providing the power !!!

Edited by DrAllis - 13 Nov 2023 at 5:53pm

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3518

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2023 at 6:06pm Posted: 13 Nov 2023 at 6:06pm |

|

Good information. This thread should probably be transferred to the knowledge base section?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

gleaner1 wrote:

gleaner1 wrote: