| Author |

Topic Search Topic Search  Topic Options Topic Options

|

BLee Mn

Orange Level

Joined: 12 Sep 2009

Location: Montevideo Mn

Points: 680

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 45 puller wheels Topic: 45 puller wheels

Posted: 15 Aug 2023 at 8:18pm |

|

would like to put 34 or 38 inch rubber on my 45 puller was wondering what or how to mount wheels to 8 bolt pattern, seems like all 34 or 38 wheels are 9 bolt

|

|

Cowboy UP

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Aug 2023 at 8:52pm Posted: 15 Aug 2023 at 8:52pm |

|

I've done it three different ways, all of them utilizing the original 8-bolt hole OEM wheel center. One way is to leave the OEM wheel center bolted to the tractor and roll your 9 bolt dual wheel up against it and bolt them together using the four square punched holes that would hold a donut wheel weight. Uses 3/4" bolts and nuts and maybe some thick flat washers. Second way is to cut out the 9 bolt hole circle and cut out the 8 bolt hole circle and overlap them one inch and weld them together with welds on the inside and outside. This takes some time and finesse to get them centered and to roll true without wobble. This is the lightest weight of the three ways. Third way is using that faithful and strong OEM wheel center and make four "spokes" ( 3/8" thick x 6 inches wide flat steel) to weld to its OD and weld to a 34/38 inch wheel blank. Always remember not all 9-bolt dual wheels are created equal. Some will position your tires closer or farther away from the tractor, maybe causing fender interference. Some dual wheels are thicker for use on 100+ HP tractors and some are quite light weight. Going from a 14.9 x 28 to a 15.5 x 38 is usually about a 15% speed increase.

Edited by DrAllis - 16 Aug 2023 at 12:18am

|

|

BLee Mn

Orange Level

Joined: 12 Sep 2009

Location: Montevideo Mn

Points: 680

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Aug 2023 at 9:50pm Posted: 15 Aug 2023 at 9:50pm |

|

currently running 18.4x28s in 3rd gear still have plenty power at end of pull was thinking of going to 18.4x34s

|

|

Cowboy UP

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2023 at 5:37am Posted: 16 Aug 2023 at 5:37am |

I use a 8 to 9 bolt adapter. CAP Brothers makes them. This does add a bit of weight for the adapters, maybe 20 lbs each.

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5192

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2023 at 10:34am Posted: 16 Aug 2023 at 10:34am |

If you look around there are some 8 bolt centers that fit the 38" rims. Lots of people cut the center bolt circle out of the 8 bolt center and weld it onto a 9 bolt center. There are many different options that could work. If you want a taller tire than an 184X28, why not find a pair of 18.4X30 tires with drop center rims that will fit to the same centers as a 28" flat base rim. 38" & 34" tires take surprisingly more power to spin than most people realize.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

cms

Bronze Level

Joined: 29 Nov 2010

Location: collinsville il

Points: 70

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2023 at 11:23am Posted: 21 Aug 2023 at 11:23am |

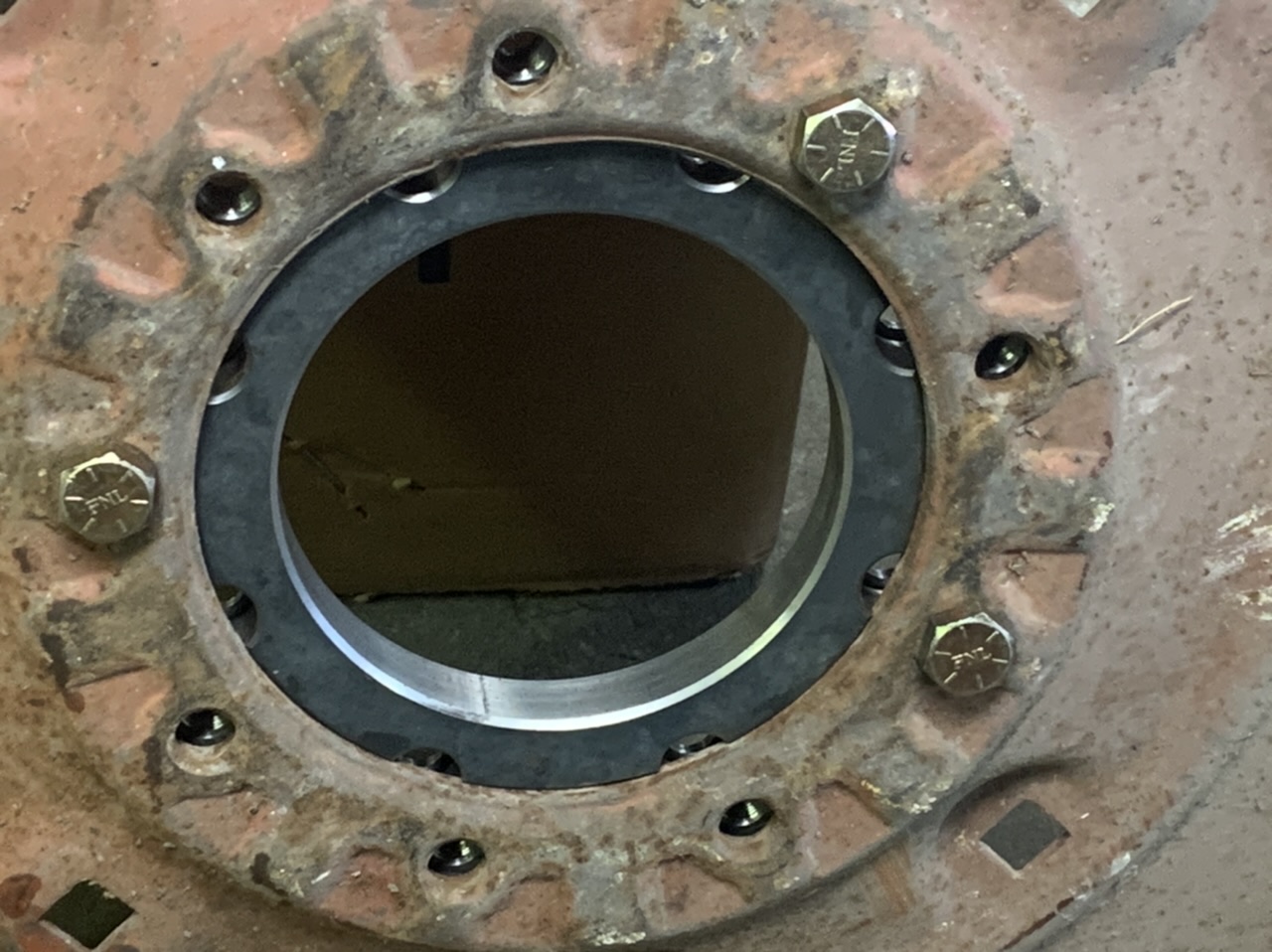

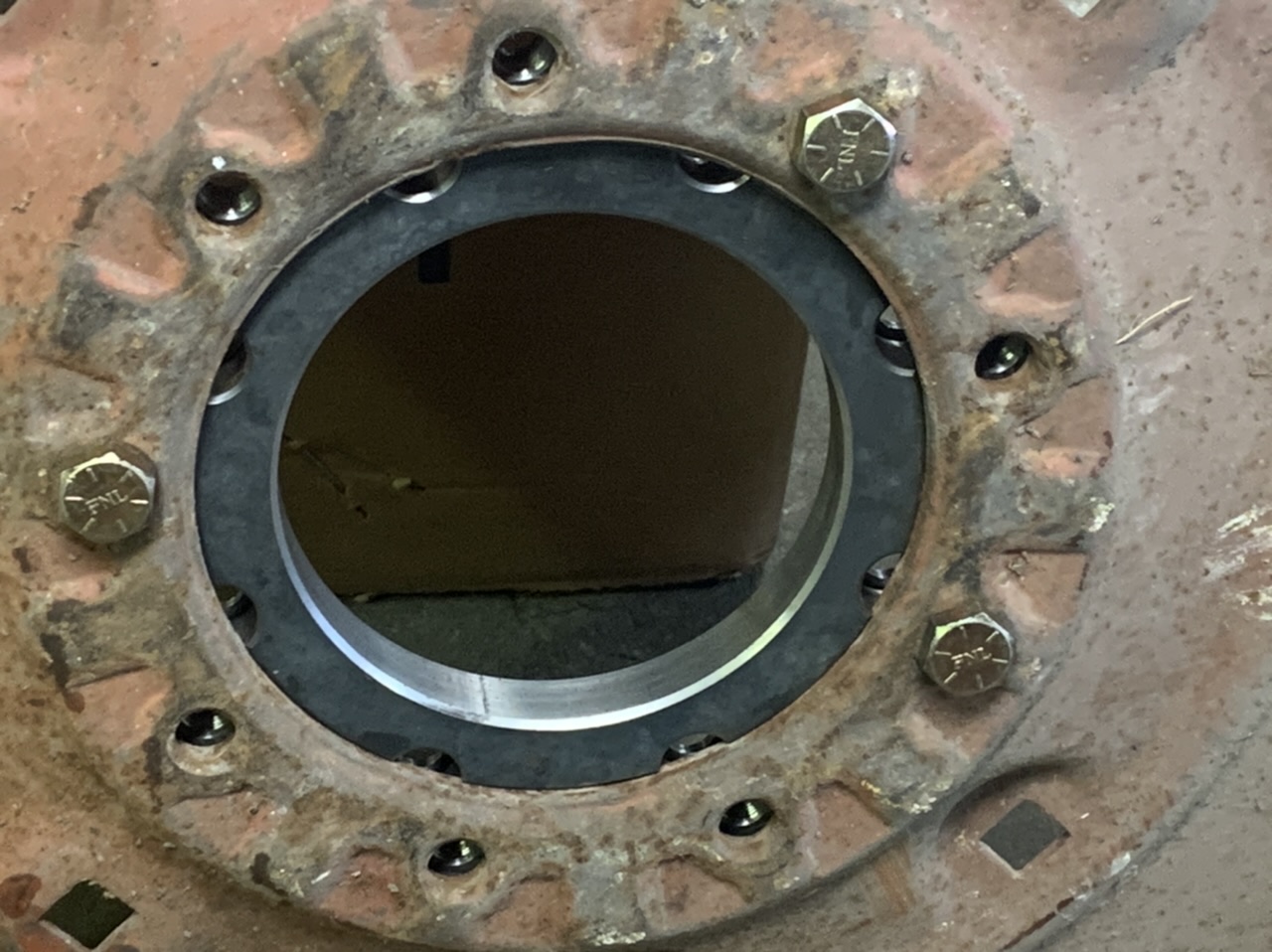

These will work.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2023 at 3:54pm Posted: 21 Aug 2023 at 3:54pm |

|

Weight for each ?? When I had my WD with 8-speed tranny in 3500 lbs I couldn't have used those.

|

|

cms

Bronze Level

Joined: 29 Nov 2010

Location: collinsville il

Points: 70

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2023 at 8:05am Posted: 22 Aug 2023 at 8:05am |

|

Weight is around 20 each with bolts. Made out of 1” material. Probably could lighten up some. Will have to try that on the next run. Have 1 set ready to go.

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Aug 2023 at 7:50am Posted: 23 Aug 2023 at 7:50am |

When i built my UC puller, I had a 1/2 center plate machined to my bolt pattern and welded it into the wheel center after cutting it to fit. While i was working on these, i removed the entire center from the rim and spaced it to allow about 1 inch clearence of the rim to the UC final drive. 34" tires are not tall enough to clear the finals and 38" would be way to fast, this put me narrower that factory stance for hauling but still spaced out for pulling. lighter than adapter but not interchangable now, but i can make 5000 with me on it running max tire size. 16.9x34. Yes that is a locating dowl pin, UC used 5 bolts and a blank hole with a dowel. No threads in #6. if i can ever get a damn engine built, maybe i will be able to turn them.....

Edited by CAL(KS) - 23 Aug 2023 at 7:58am

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)