| Author |

Topic Search Topic Search  Topic Options Topic Options

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 615 industrial lower link arms Topic: 615 industrial lower link arms

Posted: 07 Jun 2022 at 9:29pm |

Hello All;

I searched forums for this question but did not find a topic on it. Please direct me if this topic already exists.

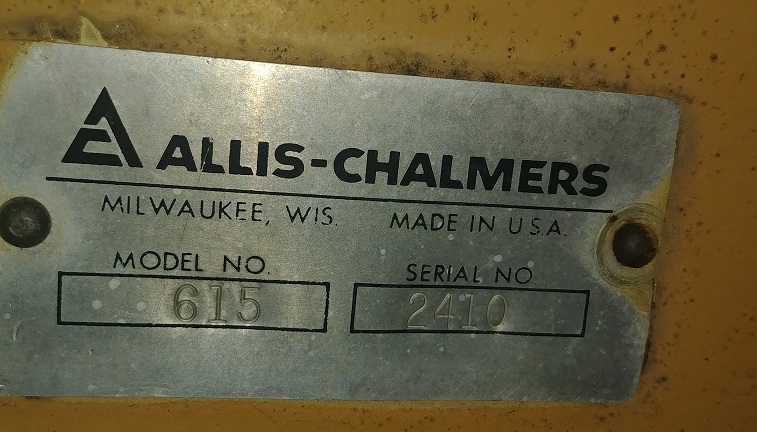

I have an AC 615. I thought it was a '61 until I found out that they started in '65 (give or take). Serial #2410. I have a very heavy duty box grader attachment on the back with hydraulic controls. Both of the lower link arms on that box grader had been bent and repaired before she was mine. They finally gave out.

Are these lower link arms specific to AC or specific a 615 or can I use any over the counter link arms of the same length? Any thoughts or assistance is greatly appreciated.

|

|

|

Sponsored Links

|

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54959

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 4:28am Posted: 08 Jun 2022 at 4:28am |

|

First off, welcome to the forum! Just out of curiosity, can you post pictures of the arms? I believe the arms are a simple straight arm, and will interchange with off the shelf parts, that tractor stores can get. But having the picture here will spur discussion...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 6:05am Posted: 08 Jun 2022 at 6:05am |

|

I wonder if the 615 had the same worthless 3pt as the D15 farm tractor?

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 8:58am Posted: 08 Jun 2022 at 8:58am |

Thank you for the warm welcome DiyDave. I'll post a couple pictures. This tractor was literally the only thing I owned that survived a terrible forest fire 9 years ago that wiped out my property. The tires and hoses all burned off and she is scorched on the opposite side from the picture. new tires, hoses, oils, and bam! she fired right up!

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 9:00am Posted: 08 Jun 2022 at 9:00am |

not sure I understand the picture posting yet...

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 9:01am Posted: 08 Jun 2022 at 9:01am |

|

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 3:52pm Posted: 08 Jun 2022 at 3:52pm |

|

Yep, looks just like the AG tractor 3pt. Not one of Allis Chalmers better engineered items. You'll be better off if you take the center to center measurement and try to find a generic pull arm. If AGCO would have a new part available you'll need a loan to buy a pair. That hitch will NOT tolerate turning with the implement engaging the ground.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54959

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 5:17pm Posted: 08 Jun 2022 at 5:17pm |

As Paul said, measure the length of the arms, C to C, and where the lifting hole is. Also make sure the replacement arm is not thicker than the lift screw ears allows to fit. Also, crawl under, and look for 3 bolts that screw into the transmission housing, vertically, from underneath. These 3 bolts (or studs or a combo) hold the whole shebang together, and have a nasty reputation of backing themselves out, when you least expect it! Be careful if you remove them for replacement, you may be in for an oil bath, I can't remember if any drain the compartment above...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 5:46pm Posted: 08 Jun 2022 at 5:46pm |

Thanks very much gents - greatly appreciate the help. I managed to find a parts manual and found the arms and original AC part numbers (left and right) - a lot of good that did me! (sarcasm...)

Any thoughts about what year it might be? I've searched for a serial number listing but apparently that information is very elusive. Even a guess?

Thanks again.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89929

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 6:02pm Posted: 08 Jun 2022 at 6:02pm |

|

the strength of any BEAM is dependent on the WIDTH and the HEIGHT of the beam ( 3 point arm).... A little extra WIDTH will help, but an inch TALLER on the HEIGHT would add a lot of strength.... You can fudge a little on the total length, but you do need a HOLE close to the present one for the lift arms.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89929

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 6:06pm Posted: 08 Jun 2022 at 6:06pm |

A 4600 FORD tractor is over 50 HP, so larger than the 615..... you might ask this guy some questions to verify fit. ( type "3 point hitch lift arm" into E-bay.)

Edited by steve(ill) - 08 Jun 2022 at 6:08pm

|

|

Like them all, but love the "B"s.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54959

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 7:46pm Posted: 08 Jun 2022 at 7:46pm |

craigmcderm wrote: craigmcderm wrote:

Thanks very much gents - greatly appreciate the help. I managed to find a parts manual and found the arms and original AC part numbers (left and right) - a lot of good that did me! (sarcasm...)

Any thoughts about what year it might be? I've searched for a serial number listing but apparently that information is very elusive. Even a guess?

Thanks again. |

If I had to guess, I'd say 1973+ C. H. Wendel's book has listings of serial #'s for 600, and 630's, but not 615's...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2022 at 9:48pm Posted: 08 Jun 2022 at 9:48pm |

Both great tips Steve - I see a wide array of them on ebay. My measurements appear to be 32" overall center to center and 19" center (tractor side) to the lift arm hole. And I do understand the physics of the wider arm vs. a thicker arm that you pointed out, but I hadn't thought of that! DiyDave - that sounds about right on the year. But I'm kinda disappointed it isn't 1961 as I had thought since that's also the year I was manufactured...  But younger is better!

Good day all.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jun 2022 at 8:20am Posted: 09 Jun 2022 at 8:20am |

Did Allis keep the traction (draft) control on the 615? Those big brackets are they for a backhoe?

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jun 2022 at 9:09am Posted: 09 Jun 2022 at 9:09am |

Hello BrianC. Being a weekend type user of my tractor, I'm not all that familiar with draft control. I *think* one of my control levers will control/limit the height of the box grader (with separate control for the tines inside the box grader), but I don't believe it has a control that will control/limit the depth of the box grader. I'm sort of guessing here so I could be completely wrong about that.

As for the brackets, the 615 did have a backhoe attachment available and I believe those brackets are for that mount. I don't have the backhoe on mine (obviously).

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jun 2022 at 8:26am Posted: 10 Jun 2022 at 8:26am |

steve(ill) wrote: steve(ill) wrote:

the strength of any BEAM is dependent on the WIDTH and the HEIGHT of the beam ( 3 point arm).... A little extra WIDTH will help, but an inch TALLER on the HEIGHT would add a lot of strength.... You can fudge a little on the total length, but you do need a HOLE close to the present one for the lift arms. |

Hey Steve; In your opinion, how close is "close enough" for the lift arm hole? Give or take maybe 2" or is that too much? Thx.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89929

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jun 2022 at 9:10am Posted: 10 Jun 2022 at 9:10am |

as you move the hole CLOSER to the tractor, the lift arms have to lift with MORE FORCE to raise the blade... as you move the holes FURTHER OUT toward the blade, it is EASIER and LESS FORCE for the cylinder to raise the blade...

If your holes are moving OUT , then you have no problem at all... If your holes are moving IN TOWARD THE TRACTOR, the cylinder ( hydraulic pressure) will go up.. AS long as your not running over relief now, you should be OK.

another example is if the ARM LENGTH is 2 inches longer on the NEW arm, and the LIFT HOLE is 1 inch LONGER compared to the Old arm.... Then your RATIO of LIFT HOLE to TOTAL LENGTH has not changed and there will be NO DIFFERENCE in lift capacity........... as you move the HOLE OUT toward the blade, you will reduce your TOTAL LIFT HEIGHT maybe an inch... again, not a big deal.

Edited by steve(ill) - 10 Jun 2022 at 9:15am

|

|

Like them all, but love the "B"s.

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jun 2022 at 10:09am Posted: 10 Jun 2022 at 10:09am |

That is an amazingly clear and concise explanation Steve. I get it.

Thank you very much for taking the time to help me. I'll buy you a few cold beers next time I see you!

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2023 at 1:28pm Posted: 09 May 2023 at 1:28pm |

Hello again gentlemen. I'm back with a new twist on my AC 615 in this forum. Thanks to you and a lot of searching, I found and installed new lower link arms this winter. That said, I am ready to reattach the large box grader on the back of my tractor.

The tractor received a lot of use since the box grader came off. The rear hydraulics are no longer very responsive. It takes 10 minutes or so for them to raise from all the way down to their highest position and it's worse when cold. I thought I was low on hydraulic fluid so filled that - overfilled it actually (embarrassed).

The hydraulic fluid appears to be almost a touch foamy. It has a lot of tiny air bubbles. I thought that might be the issue so spent a lot of time raising and lowering the arms hoping to drive any air out. Didn't work. I'm hoping it isn't the pump going bad b/c that feels like it would be an overwhelming job for me.

Any thoughts or ideas about sluggish rear hydraulics in an old AC 615? Thanks in advance!

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54959

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2023 at 4:43pm Posted: 09 May 2023 at 4:43pm |

Air bubbles aren't good. check the strainers/filters for the hyd system...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2023 at 7:31pm Posted: 09 May 2023 at 7:31pm |

|

Do you have a front pump for the loader, or run it all off the tractor sump pump? My old Massey 65 with loader sometimes gets funny in the valves that switch the sump pump pressure from loader back to the three point. I have to cycle them a little and then everything is back to normal. Sticky 'floater' valve in there some where.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89929

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2023 at 7:59pm Posted: 09 May 2023 at 7:59pm |

as Corey asked.. does the loader and rear lift use the same hydraulic tank and pump ? Does the rear hydraulics have a quick coupler hose or all internal ( appears to be factory internal cylinder )? .... if you blow a hose on the internal cylinder, you will get air and loss of lift PSI.

Air bubbles in the oil are cavatation... Too thick of oil, restriction in the suction line, hose ruptured, cylinder packing leak ( internal cyl) etc.

Edited by steve(ill) - 09 May 2023 at 8:04pm

|

|

Like them all, but love the "B"s.

|

|

craigmcderm

Bronze Level

Joined: 07 Jun 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 May 2023 at 11:06am Posted: 10 May 2023 at 11:06am |

Thanks for thoughts gents. Hi again DIYDave.

The hydraulics for the front (loader bucket) is mounted in the front of the engine. Rear attachments (box grader, backhoe, etc.) are a separate pump. Controls are completely separate as well. The rear pump is inside the cavity of the body of the tractor below the seat area. That pump does not operate if the clutch is engaged (foot or shuttle). The engine has to be turning and passing power to the rear for that pump to run.

Do you think that pump would be totally immersed in fluid in the inside the tractor body? I over filled it but the problem was there before I did that. Not sure of the overfill could be causig additional problems.

Cavitation of the fluid seems like the most likely scenario and could easily be causing what I am seeing. I don't know where to find strainers or filters for the hydraulics but I will look for those. Thank you!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

craigmcderm wrote:

craigmcderm wrote: But younger is better!

But younger is better!