| Author |

Topic Search Topic Search  Topic Options Topic Options

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2876

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 160 3 point won’t raise Topic: 160 3 point won’t raise

Posted: 14 Jun 2021 at 10:12am |

|

I lowered my lift arms for something and now they won go back up. I added oil but without a good dipstick it’s just a guess.

What to look at next?

Edited by victoryallis - 14 Jun 2021 at 10:12am

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

|

Sponsored Links

|

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2021 at 10:59am Posted: 14 Jun 2021 at 10:59am |

|

I will look at my manuals when I get home from work.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 7:36am Posted: 15 Jun 2021 at 7:36am |

My user manual shows to remove the hydraulic/transmission screen to clean every 200 hours. Oil Filter at the right front of the tractor should be replaced along with the oil every 300 hours. Takes 29 quarts of AC 106 transmission/hydraulic oil. I would do that service first and see if that resolves you issue, if not let me know. Drain plugs are at the rear of the tractor underneath the transmission and hydraulic systems.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 7:38am Posted: 15 Jun 2021 at 7:38am |

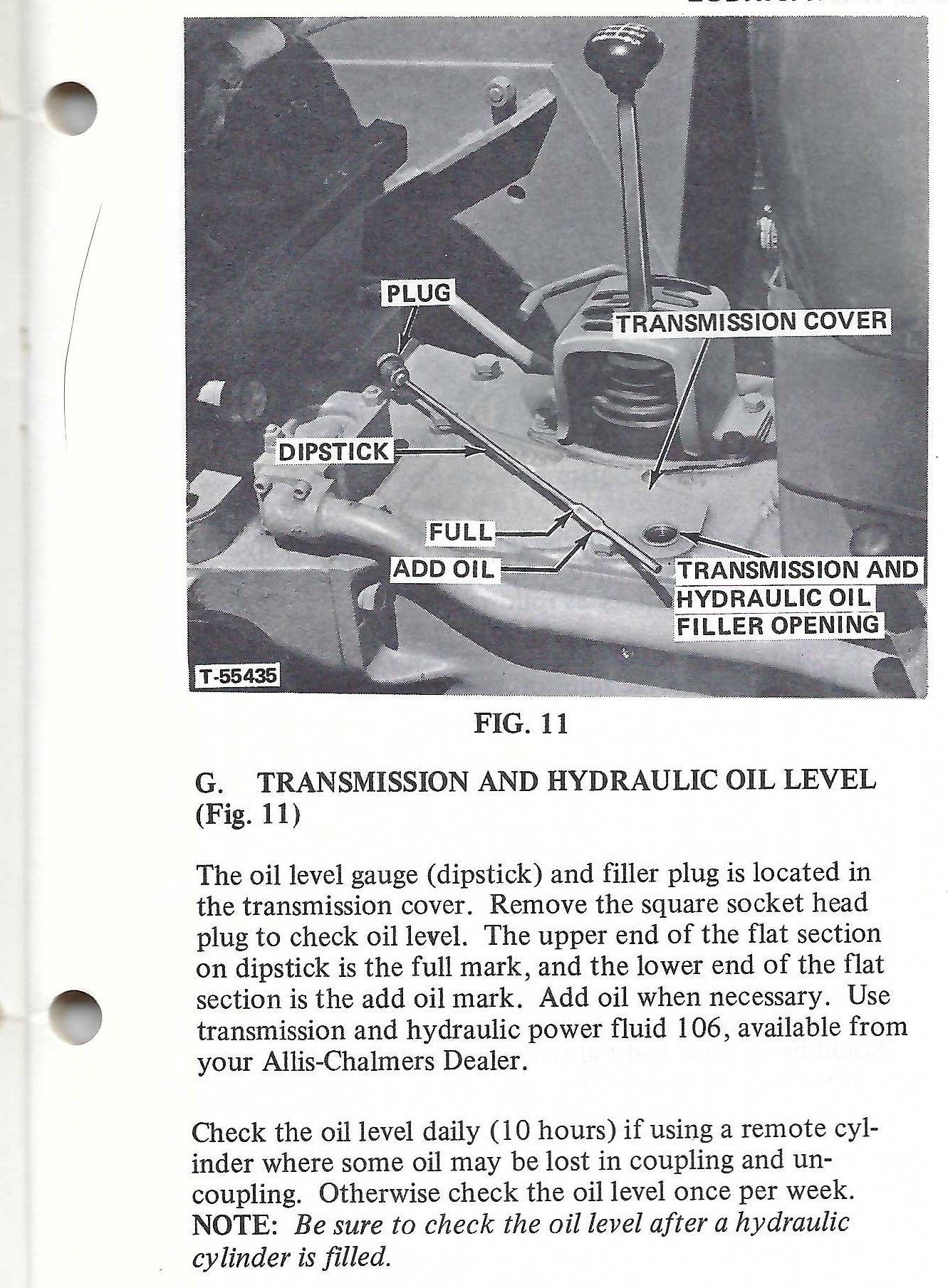

I’m sorry, the pic turned sideways

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 6:37pm Posted: 15 Jun 2021 at 6:37pm |

|

The dip stick is to the right of the gear shift, I’m sure you may already know that. 3/8” wrachet fits it.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 8:52pm Posted: 15 Jun 2021 at 8:52pm |

|

You said without a good dipstick? What do you mean by that? The dip stick is attached to the filler plug? If you don’t have a dipstick attached to it then good chance its in your trans tearing stuff up.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2876

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 9:46pm Posted: 15 Jun 2021 at 9:46pm |

|

I checked by the large hex head plug on top. Did I do it wrong?

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 10:01pm Posted: 15 Jun 2021 at 10:01pm |

|

The plug you want has a square inward head, my 3/8 ratchet wrench fits right into it so you can loosen it and tighten it with it. When you unscrew it the dip stick is attached to it. Dipstick is probably 10” long I’m guessing. If its low, your pump may have lost its prime. I would change fluids and filters first if it has been over 300 hours. There is also a hydraulic/transmission screen that needs to be cleaned. It is in front of the seat to the right. Remove 4 nuts that hold the cap and remove it. Gently pull the screen out and clean it in solvent. Also a magnet attached to the cap, clean any metal fragments from it. These small things to do will most likely have you working again.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2021 at 10:03pm Posted: 15 Jun 2021 at 10:03pm |

|

The sideways pic I posted earlier is the screen that I am referring to

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 4665

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 6:06am Posted: 16 Jun 2021 at 6:06am |

|

My cousin has a 160. Hydraulics seem to be one of the weak points. When the hydraulic pump gets worn, they have to prime the system often. They have replaced the hydraulic pump several times.

|

|

BrianC

Orange Level

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 6:56am Posted: 16 Jun 2021 at 6:56am |

|

|

|

BrianC

Orange Level

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 7:44am Posted: 16 Jun 2021 at 7:44am |

The high mark on the stick is 9.25 from the head on the plug, low mark 10.25. If you have a hex head plug of some sort, then the original got lost. I think there was the Basic model 160 that didn't have this dipstick, but instead had a horizontal plug, perhaps under the right foot board. That cap with magnet has a gasket and 4 studs & nuts. This is an air seal, if the gasket is not good, it can suck air and loose prime.

Follow the large diameter suction pipe to the pump, it is split near the middle. They use a rubber connector hose with wire clamps. This was the reason mine was losing prime. I cleaned it, and tightened the clamps. This has been good for many years now. Prior to that I was looking up prices on new pumps, so whew, a zero dollar fix. Also, when it did lose prime, before I fixed the air leak, I had to remove the plug at the pumps high pressure output to bleed out the air. This got me going until I shut down for some time. High pressure hydraulic fluid is dangerous. Will shoot out 10 feet, and it happens guickly.

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6358

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 8:19am Posted: 16 Jun 2021 at 8:19am |

Not sure if this helps any

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

BrianC

Orange Level

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 8:50am Posted: 16 Jun 2021 at 8:50am |

Thanks Charlie for the video link. In typical Allis fashion, they had numerous One-Sixty/160 hydraulic configurations. So there is a large hex plug for filling only on some models.

Also I mentioned a gasket on that metal cap with the magnet. You can see it is really an o-ring. Not talking about the o-ring in the top end of the plastic strainer.

With my tractor, cleaning the plastic strainer and filling properly with oil did not fix my issues.

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6358

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 9:16am Posted: 16 Jun 2021 at 9:16am |

|

His strainer was junky!

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

bozrae

Bronze Level

Joined: 02 Jul 2012

Location: Michigan

Points: 160

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 9:30am Posted: 16 Jun 2021 at 9:30am |

Did you lose all hydraulics or just the 3 point won't lift? Had a 160 for about 20 years, never had a problem with the 3 point lift system, but did have the main hydraulic filter mostly plug up. The filter is located in a metal housing laying horizontal underneath the fuel tank on the right side of tractor. I believe you have to remove a side panel to access. Should be a hex head on the filter housing cap that you need to remove. I not longer have the 160 so I can't go out and check. I think they made a couple variations of the filter, but the one I had was made out of thin metal fins and was washable. I used mineral spirits and compressed air to clean. Hydraulics worked fine for many years after that.

|

|

D15D, D17G, 170G, 175D, and two 5050FWA

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 10:50am Posted: 16 Jun 2021 at 10:50am |

|

Good job finding a video Charlie. Differences in the location of checking the oil on a One Sixty and 160 series is surprising. Never would have thought it originally did not have a dip stick. Being new to this model, I am enjoying this thread to learn more about it. Some good advice handed out. Video shows what happens when poor maintenance practices catch up with ya.

Edited by AC720Man - 16 Jun 2021 at 10:51am

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6358

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 11:07am Posted: 16 Jun 2021 at 11:07am |

|

What Renault model was the 160 based on? 56?

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 7:44pm Posted: 16 Jun 2021 at 7:44pm |

Have to do some research on that. AC had very little info on these tractors as they were only from 1970-75. Production stopped because of the price increases from France. So I came home and wanted to check my screen and it was very clean which did not surprise me because of the previous owners maintenance schedule. Some tiny metal shavings which stuck to the magnetic and little bit on the screen. No other foreign matter.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 7:46pm Posted: 16 Jun 2021 at 7:46pm |

|

That is what appears to be some paint flakes in the bottom, guessing. Cleaned right up.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

BrianC

Orange Level

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2021 at 8:33pm Posted: 16 Jun 2021 at 8:33pm |

I think it was based off the Renault R56 (Renault code 7251). Not 100% on that 7251, there were a series of R5x tractors.

The One Sixty tractor was Renault code 7301. You can look through tractor websites in Europe for info on R56. Google can translate somewhat. Talk of 3pt issues.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4924

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Jun 2021 at 6:43pm Posted: 18 Jun 2021 at 6:43pm |

|

Victoryallis, have you found the problem yet?

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Tswarner67

Bronze Level

Joined: 21 Oct 2024

Location: Ohio

Points: 3

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2024 at 1:08pm Posted: 21 Oct 2024 at 1:08pm |

|

Also curious, just got a one-sixty .. had been sitting almost a decade under a tent . Lady wanted it out of her yard, changed all the fluids and cleaned all filters. Got it running , driving , stopping, bucket working, and remote hydraulics working. Just can’t get the darn 3 point to move it’s stuck up.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)