| Author |

Topic Search Topic Search  Topic Options Topic Options

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 6080 external thrust bearing Topic: 6080 external thrust bearing

Posted: 25 Nov 2020 at 1:38pm |

|

Hi everybody! I am new to the forum. I have recently undertaken the task of saving a early model 6080 for a friend. It hasn't been ran in roughly 15 years, it does now. The question I have is with the external thrust bearing. How is it shimmed or adjusted? Are there even replacement parts available? I have all the manuals(operators, service and parts) however, that is not even listed. The pto wont engage at all. The tractor runs and drives and brakes all work. Several weekends of fussing with it. But the bearing in the bra has me perplexed... thanks

|

|

|

Sponsored Links

|

|

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2020 at 3:37pm Posted: 25 Nov 2020 at 3:37pm |

Pics of tractor:

|

|

WNYBill

Silver Level

Joined: 04 Jun 2016

Location: WNY

Points: 276

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2020 at 8:36am Posted: 26 Nov 2020 at 8:36am |

Can't help you with the bra. The PTO is an abomination. The 6000 series is a Fiat Tractor with a Allis engine.

Has the tractor been run with the PTO clutch lever pulled back? That is what puts pressure on the crank bearings. There is a good possibility that the PTO clutch is "frozen" or just out of adjustment. It is cable operated. There is a shaft that goes through the torque tube that may be seized, that is what operates the front clutch, the PTO clutch. Try lots of penetrating oil and moving it side to side as well as rotating it. Tractor has a duel clutch, not a 2 stage clutch.

When everything is working the 6000 series is a handy tractor. I see yours has a new seat.

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2020 at 8:50am Posted: 26 Nov 2020 at 8:50am |

The bra as no bearing on the PTO working. That just affects the crank.

The PTO, you pull back on the big stick. Then to the left of seat you pull up on the lever there to engage the PTO gear. Letting the Big stick forward will engage the PTO (Allowing it to run).

Ensure the left lever is moving the PTO engagement arm. It may be stuck

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2020 at 11:28am Posted: 26 Nov 2020 at 11:28am |

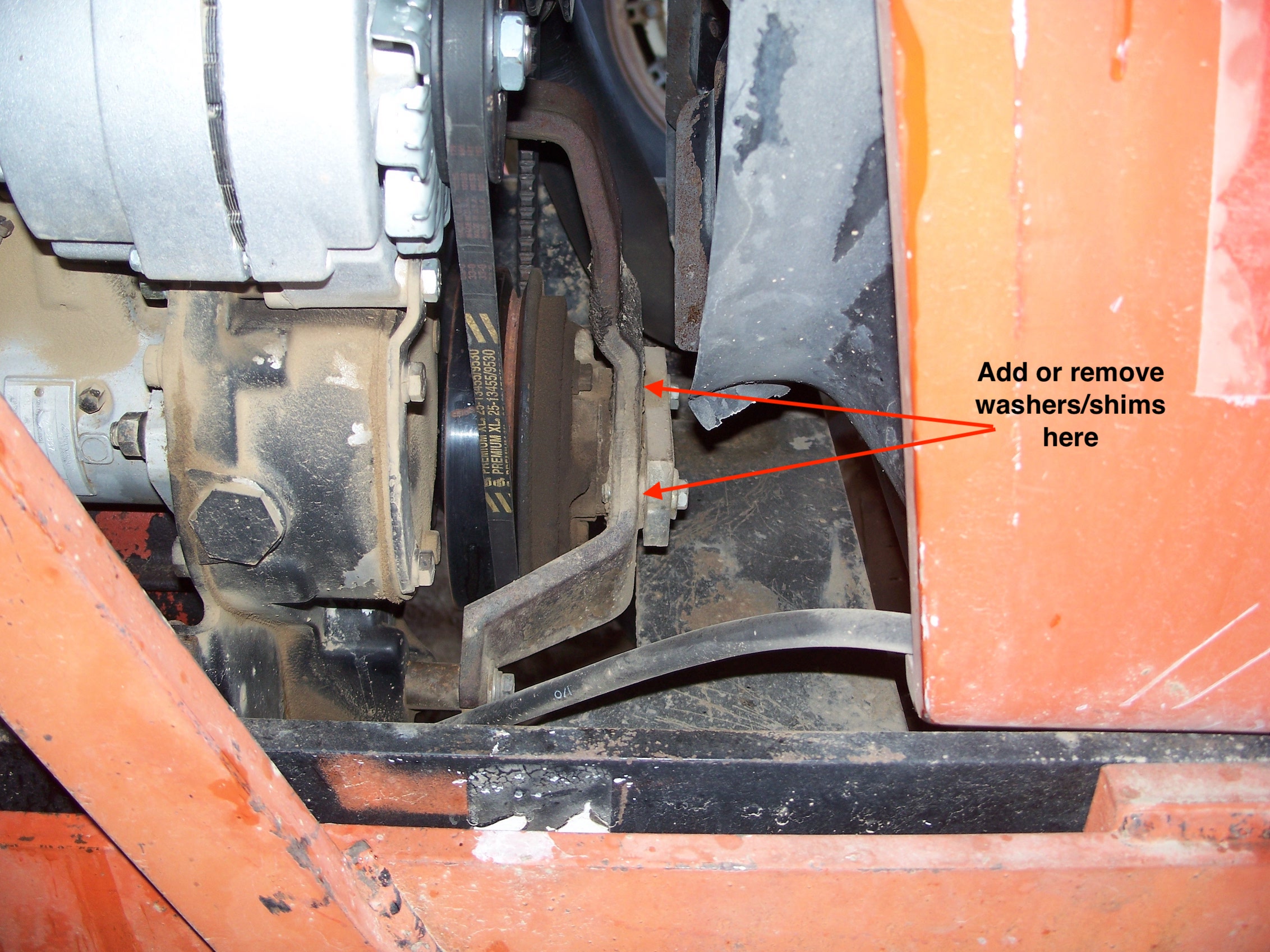

For crank end play you have to use a dial indicator, usually set it on the crank pulley and then bar it back and forth to get a measurement of how far it moves. Do a check first before you take anything apart so you have a baseline measurement. It is also a very good idea to remove that front plate and check total movement of the crank, especially if the tractor is new to you. I set mine at normal crank thrust clearance, around .005"(book shows .003 to .013), but check your total movement first just to make sure you set the thrust plate at least equal to that amount or less. Maybe you have a crank endplay of only .004(very rare) then I would try to set the thrust plate at that. DO NOT set it at zero or preload, you want normal bearing oil clearance to prevent wear. You have to add or subtract shims/washers from the front plate to change clearance. Important that you grease that bearing zerk in there at least every oil change.

|

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2020 at 5:21pm Posted: 26 Nov 2020 at 5:21pm |

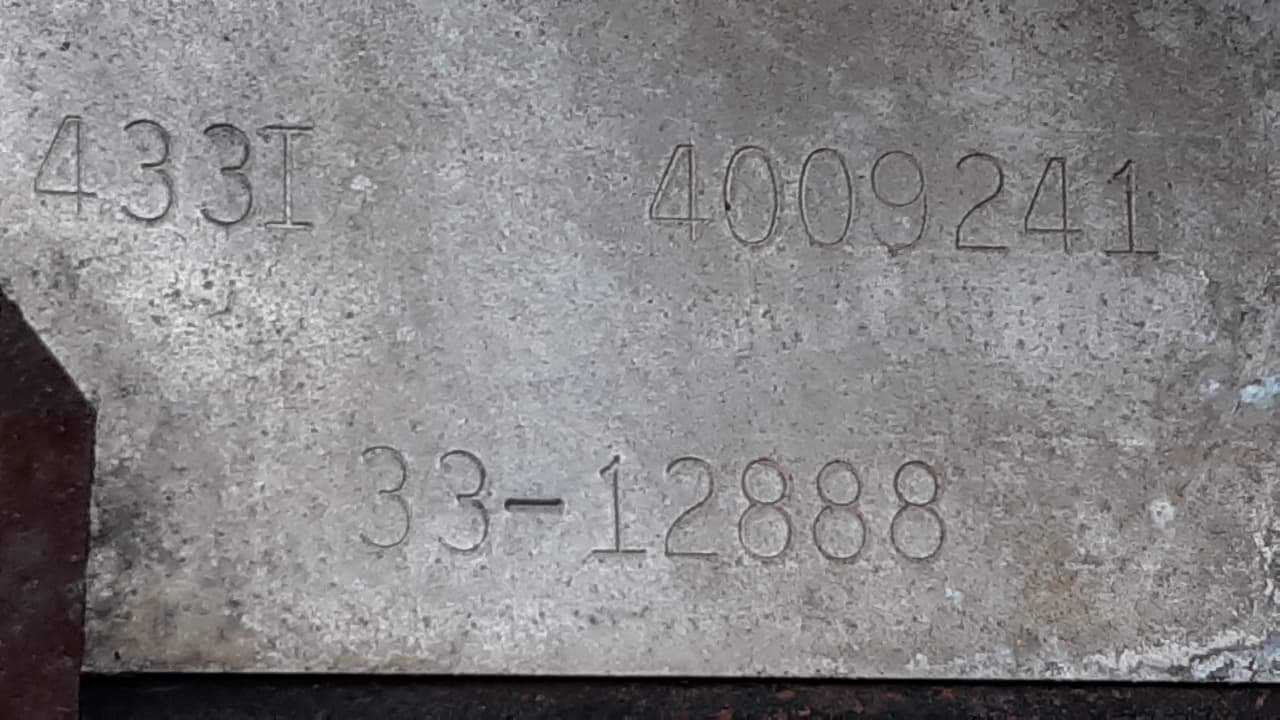

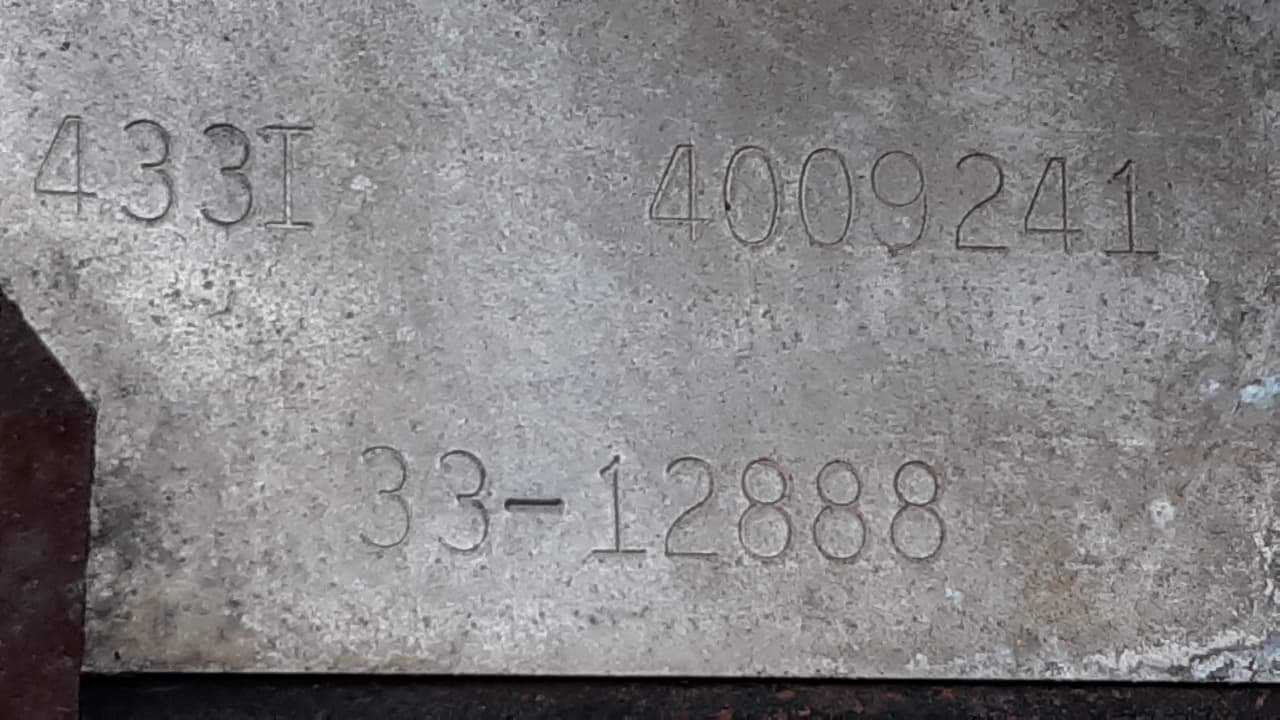

|

|

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2020 at 5:26pm Posted: 26 Nov 2020 at 5:26pm |

|

Picked up a slightly used one on ebay. Pricey but worth it. The pto clutch lever was all the way down. However, the pins going to the clutch arm were missing. New ones made on the metal lathe and installed with bronze bushings. Ordered a new clutch cable from amazon.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2020 at 9:11pm Posted: 26 Nov 2020 at 9:11pm |

|

If you have .018 end play, you need to go inside and check condition of crank and block. MACK

|

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2020 at 6:16am Posted: 27 Nov 2020 at 6:16am |

|

That's what we were thinking as well Mack. We will drop the pan today to see what's going on in there. Ended up machining. 020 off the stub shaft as it was rubbing on the plate. The pin holding the shaft to the plate was broken. Machined a new pin and put weak spot in it as the original must've had. Still fighting with the rear hydraulic cylinder to get that off. To get the PTO housing off to seal up the leak around the welded repair area.

|

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2020 at 11:11am Posted: 28 Nov 2020 at 11:11am |

Removed oil pan inspected crank and block. Did not see any damage checked bearings they looked really good for only having 3500 hrs on them. Reinstalled pan. Reinstalled stub shaft on external thrust bearing with one .030 shim on each bolt and a .042 shim on the front of the shaft to make up for the amount I milled off to reface and flatten the surfaces. Total end play now is .006. PTO still problematic in engaging. Thinking clutch fingers made need adjustment? New pto cable should be here in a few days. PTO housing is leaking at weld site. Thinking drain hydraulic oil, clean surface with oven cleaner and apply JB weld? Looking for body panels and new dash cluster. Owner wants tractor to look new at all costs. It's going to be mainly used for bush hogging and to rin a belsaw sawmill.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2020 at 8:19pm Posted: 28 Nov 2020 at 8:19pm |

|

Where are you engaging pto. Sitting in seat. Left side is a knob sticking up next to seat. That's a seasonal disconnect, which the tractor needs to be shut off to pull up into gear with out grinding. Then you let the hand clutch on right side forward to engage pto. And if your not using pto you leave hand clutch forward and leave the knob on left side down, disengaged.

Edited by Mikez - 28 Nov 2020 at 8:26pm

|

|

McGuire

Bronze Level

Joined: 25 Nov 2020

Location: Alabama

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2020 at 7:30am Posted: 29 Nov 2020 at 7:30am |

|

We are using the rod on the left side and leaving the pto clutch lever all the way forward. Shifting it only when the engine is off, guessing it's going to be a job of adjusting the pto clutch inside the trans...

|

|

WNYBill

Silver Level

Joined: 04 Jun 2016

Location: WNY

Points: 276

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2020 at 7:51am Posted: 29 Nov 2020 at 7:51am |

|

Idle the tractor down, pull the right side handle back, pull up rod on left. If things are adjusted correctly, it should not grind. Move right lever forward to engage the PTO. I have the right lever adjusted so it will not lock back, just pull back to stop PTO temporarily. Right lever forward and left rod down when not actively using PTO.

|

|

Ky.Allis

Orange Level

Joined: 31 Jan 2010

Location: Kentucky

Points: 1036

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2020 at 9:51am Posted: 29 Nov 2020 at 9:51am |

|

This clusterf*** system is exactly why I would never own a 6000 series AC. A hydraulic PTO clutch like my 200 has would have been so simple and reliable. I know they are Fiat built tractors except for the engine and for the most part they are good tractors but the PTO clutch was just poor engineering.

Edited by Ky.Allis - 29 Nov 2020 at 4:48pm

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2879

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2020 at 7:16pm Posted: 29 Nov 2020 at 7:16pm |

Ky.Allis wrote: Ky.Allis wrote:

This clusterf*** system is exactly why I would never own a 6000 series AC. A hydraulic PTO clutch like my 200 has would have been so simple and reliable. I know they are Fiat built tractors except for the engine and for the most part they are good tractors but the PTO clutch was just poor engineering.

|

It’s really a no issue we got one with 11,000 hours, another with 9000+, another that reads 6500 but based on condition compared to the one with 11,000 the 6,500 hour one has 16,500 hours. Ours do a fair amount of PTO work. I’ll take the fuel efficiency and nimbility of 6000 series. New York Bill way over plays the long PTO lever. For YEARS we left the long lever back between fields haying or between loads spreading manure. Even if you do the seasonal disconnect it takes what max 15 seconds?

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

ssefick

Bronze Level

Joined: 09 Feb 2022

Location: South Carolina

Points: 137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2022 at 9:10pm Posted: 10 Mar 2022 at 9:10pm |

|

Hello, I just bought a 6080, and I need to check the bearing play. I do not know how to do this.

Do you mean a wheel bearing dial indicator? When you say bar it back and forth. Do you mean like use a crow bar?

I do not want to break anything trying to fix fix the tractor.

Thank you for all of the help!

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8731

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2022 at 3:19pm Posted: 11 Mar 2022 at 3:19pm |

|

The idea is to pry fore and aft. The pulley is easiest and any bar you come up with to do the job. Without prying pressure and dial indicator you will not know what the true end play is.

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 8390

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2022 at 1:11pm Posted: 12 Mar 2022 at 1:11pm |

|

Thats quite a fix Allis came up with to hold the crank back- combine engines have no pressure against them so kinda the weakness showed up - must have cost AC a bundle in under warranty $$$$$$$$$

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22305

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2022 at 8:06pm Posted: 12 Mar 2022 at 8:06pm |

|

The crankshafts thrust bearing on the 6060-70-80 was/is the same as a 180-185-190-190XT-200-7000. It was plenty for all those models, but when combined with the European designed dual clutch (traction and PTO clutches) it was borderline overloaded. This was especially true when someone has the stage coach handle pulled back and locked and then stepped on the foot clutch to start a cold engine with no oil pressure.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Ky.Allis wrote:

Ky.Allis wrote: