| Author |

Topic Search Topic Search  Topic Options Topic Options

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: WD hydraulics problem Topic: WD hydraulics problem

Posted: 18 May 2020 at 2:01pm |

Hi gang,

I have an Allis WD that developed a hydraulic problem, I'm hoping somebody here can let me know that I missed something obvious?

It came to me with a 3rd-party loader, and I've used it for snow removal and dragging my driveway & trails for 7 years now, so I'm pretty familiar with it. The lack of power steering combined with heavy snow in a trip-bucket over a tricycle front made me wanting a better snow solution, so I picked up a rear blower and a 3-point add-on kit from OK Tractor.

After I installed the 3-point add-on hardware, I had no hydraulics. I hadn't touched anything hydro yet, the tractor was backed into the shed & I was planning to nose it in, remove the loader, then tweak the hydro so it would run the rear 3pt instead of the bucket, but the bucket wouldn't raise.

So I took apart the pump. I ordered new springs & gaskets before I took it apart, just assuming a spring had broken. When I got it broke down, the springs were fine (replaced them anyways), the only thing I noticed was a bunch of gunk. Hoping that it was just clogged, I scrubbed everything & put it back together. Since I was at it, I also replaced the lines going to the rear cylinders.

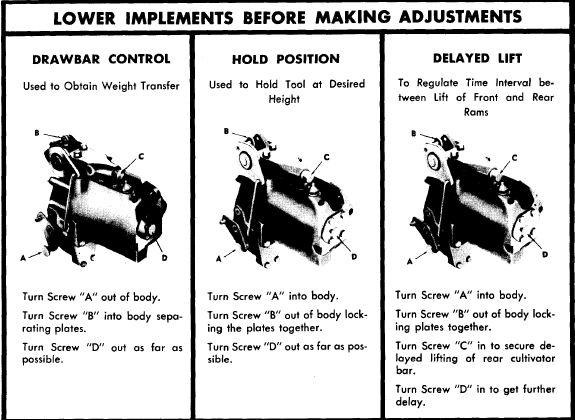

I have the Service Manual, Operating Instructions, & Dealer Parts Catalog, I went though all 3 looking for any clue. I have tried every combination of screws A/B/C/D, plates locked, plates unlocked, etc, etc, etc, to no avail. I even took off the line to one of the rear cylinders, no fluid comes out. It's obviously bypassing or clogged somewhere, but I'm at a loss on what to try next. Any and all advice is greatly appreciated!

|

|

|

Sponsored Links

|

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 800

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 May 2020 at 3:27pm Posted: 18 May 2020 at 3:27pm |

|

I Just Did One That Somebody Had A Part The Ball Was Missing In The Unloading Value

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87703

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 May 2020 at 4:12pm Posted: 18 May 2020 at 4:12pm |

|

It worked until you added the 3 point, then stopped ? I would look at WHAT CHANGED... Did you change the oil ? Is it full and Hydraulic ? .... The pump has a HOSE coming off of it that runs your loader... How did you tie the 3 point into the system ? Take the hose off the pump and see it if has out put... Does the loader work ? What was replumbed ?

|

|

Like them all, but love the "B"s.

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2020 at 8:47pm Posted: 18 May 2020 at 8:47pm |

|

Great questions, Steve.

Before I touched anything, the rear arms would drift up and down with the loader, they're tied together with a T, I did not re-plumb anything before it broke. The only thing I did was add mechanical weight off the rear arms.

Nothing moves now, the loader does not lift, the rear arms do not lift. I took a hose off and if the rear arm cylinders, no fluid comes out. The fluid level was fine when it initially broke, and I made sure to put it to the high side of the fill mark after I put everything back together.

I was sure that there was going to be a broken spring causing fluid bypass, but like I said initially, all the springs were good. I replaced them anyways just because I had new ones, but nothing has changed, so that wasn't it. What else could cause complete fluid bypass?

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2020 at 8:55pm Posted: 18 May 2020 at 8:55pm |

|

Is your TB linkage hooked up? Is linkage to hand lever adjusted properly? MACK

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87703

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2020 at 10:00pm Posted: 18 May 2020 at 10:00pm |

|

Eric, i just seems like too much of a coincidence that the hydraulics STOPPED right after you put on the 3 point. Are you sure that the hoses are OK.. not possible that the pressure hose is routed back to the oil sump ? Just seems odd that it happened right then..... I guess the pump is engaged and running ? No change to make you think the pump drive is not rotating ?

|

|

Like them all, but love the "B"s.

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 10:45am Posted: 19 May 2020 at 10:45am |

Hi Mack,

I'm not sure what exactly you mean by "TB linkage"? I would read that as "throttle body"  , which wouldn't apply. You surely are talking about something else?

Regardless, I've triple-checked all the linkages, and re-adjusted most of them twice, just in case.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8617

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 10:58am Posted: 19 May 2020 at 10:58am |

|

Traction Booster TB it's all in the books you say you have

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 11:01am Posted: 19 May 2020 at 11:01am |

I agree copmpletely Steve. I didn't touch a hose, I did not touch a single adjustment on the pump. The only thing I did was pull the drawbar out of the snap coupling, bolt a bunch of stuff to it, then hang it all back up.

My best guess was that there was residual gunk in the rear arm cylinders, and hanging the extra weight broke it free, then it migrated into the pump valves. That's why I pulled the pump off & rebuilt it. It *was* really gunky, but it's clean now, and I didn't improve anything.

I'm baffled.

This afternoon I'm going to get fittings so I can plug a pressure gauge directly into the pump...but I already took off the far end of a new line & no fluid came through, so I assume it to be zero-pressure.

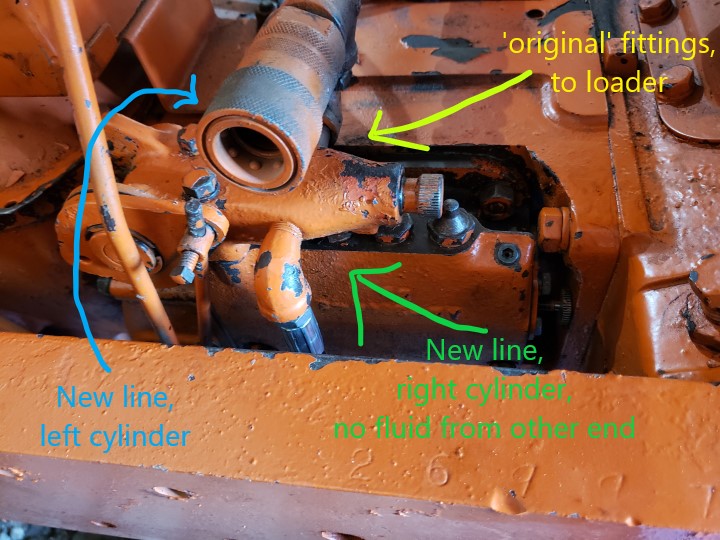

Is there any difference between the 3 ports? Here's what I am working with:

|

|

farmtoybuilder

Orange Level

Joined: 11 Sep 2009

Location: Dresden,Ohio

Points: 1457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 11:34am Posted: 19 May 2020 at 11:34am |

|

both cylinders would use same pressure line from pump with a tee and separate hoses to them.

|

|

5 different TT-10's,5 TT-18's Terra Tigers,B-10,2 B-207's,B-110,2 B-112's,HB-112,B-210,B-212,HB212,2 Scamp's & Homilite T-10. Still hunting NICE HB-112 & anything Terra Tiger & Trailers for them.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87703

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 12:21pm Posted: 19 May 2020 at 12:21pm |

i would unscrew the quick disconnect that use to supply oil to the loader. ( i have seen those fail and not couple up correctly).... Then see if oil comes out of that hole... If so, you should have a TEE on it and go to both 3 pt cylinders... Im not sure what the small hose that says RIGHT CYL is... im not that experienced on the WD hyd valve.

again, look at the lever on the pump ... is it moving properly when you move hand lever ? Can you hear anything DIFFERENT when you pull the lever ... and there is mechanical power to the pump so it is rotating ?

Edited by steve(ill) - 19 May 2020 at 12:40pm

|

|

Like them all, but love the "B"s.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8617

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 2:13pm Posted: 19 May 2020 at 2:13pm |

|

You filled it with fluid...did you double check it for full? No priming required on these. They are self priming. Can't imagine it won't push fluid out a loose line even if it's not up to snuff. Everything you are saying makes no sense so it's hard to help.....The foot clutch isn't locked out is it? Tractor won't travel if it is and pump won't run.

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 3:15pm Posted: 19 May 2020 at 3:15pm |

SteveM C/IL wrote: SteveM C/IL wrote:

....The foot clutch isn't locked out is it? Tractor won't travel if it is and pump won't run. |

Oh sh*t. Before I pulled the hyd pump, I was pulling the sump plugs & accidentally pulled the one for the transmission....I locked out the foot clutch so I could get to the refill plug!

That's the first thing I check, I guess. I hope it's just that stupid....

Regarding the plumbing, this came to me with separate lines from each rear cylinder, there was no T fitting. So...does it matter? If so, which port should the T'd line plug into? I might as well put it right while I'm working on it. I thought all 3 ports had the same pressure.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87703

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 3:40pm Posted: 19 May 2020 at 3:40pm |

|

I dont know what all the ports do, but the one with the COUPLER that use to feed the loader is a good one to use.. You run a hose back, then TEE to each rear cylinder.. They should work TOGETHER and tied TOGETHER.. and SteveM is right... if there is no mechanical power to the PUMP , then it is not rotating. Thats what the CLUTCH pedal does.

|

|

Like them all, but love the "B"s.

|

|

Dave H (NE)

Silver Level

Joined: 11 Sep 2009

Location: Western NE

Points: 288

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 7:00pm Posted: 19 May 2020 at 7:00pm |

|

you have the cylinders hooked up correctly.

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 7:32pm Posted: 19 May 2020 at 7:32pm |

OK, turns out that I was a little dumb, and did have the foot clutch locked forward. I did that after I reinstalled the hydro pump, while I was topping up fluids. Also turns out that isn't the core problem. I popped the clutch off, & fluid started dripping from a hand-tight fitting, so I got pretty excited...but...

Mack had me chasing TB linkage, but best I can tell from my books, that only applies to WD-45's? Mine is straight WD, nothing in any of the books except in the parts diagram, and it specs it as 45-only. SteveM C/IL, if you don't believe me, I can send you pictures.

I had limited fittings on-hand, but I wanted to get those quick disconnects out after steve(ill) rightfully pointing out that they fail, so I mishmashed together a system without any: rear left port: gauge front left port: loader right-side port: right rear cylinder (I didn't have a tee or a plug, just wanted to test the system)

So with it plumbed like that, I fired it back up, and *NOTHING*. The needle on the gauge never even lifted off the peg. Like I said earlier, fluid seeped out of a hand-tight fitting, so *SOMETHING* is happening, but I'm completely at a loss.

All the rods and linkage are adjusted per the manual. Fluid is full, topped off a couple times just to keep the level at the top of the range.

When I move the hydro lever on the throttle quad up, I think that I might hear a faint change in the pitch, but it might be my imagination.

When I had the pump off, the cam looked fine. What's the mechanism that stops the pump when the foot clutch is pressed? Anybody know?

Also, the book calls for a spring on this nub for later year tractors, I just have the plate pinned to the body with the screw. Should there be something connected to that nub?

I forget what screw letter that is (C?), but it's the lowest/rear plate & screw.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 9:43pm Posted: 19 May 2020 at 9:43pm |

|

The TB linkage I ask about, hooks to pin with green dots around it and ? mark. MACK

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 8:30am Posted: 20 May 2020 at 8:30am |

"What's the mechanism that stops the pump when the foot clutch is pressed? Anybody know?"

The hydraulic pump is driven off a cam , which is ON the transmission input shaft. If you disengage the foot clutch, that shaft with the cams, stops turning, and the pump will not work.

ALL WD's and WD45's have the same hydraulic set up with the traction boost system.

Edited by CTuckerNWIL - 20 May 2020 at 8:30am

|

|

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 10:29am Posted: 20 May 2020 at 10:29am |

I feel like we're just talking past each other on this Traction Boost topic. I believe that on tractors that have TB equipped, it needs to be there. I'm not convinced my tractor has it, and any explanation I'm getting from you guys is not sinking in...I don't undersatand what it is, what should be there, or what I should look for.

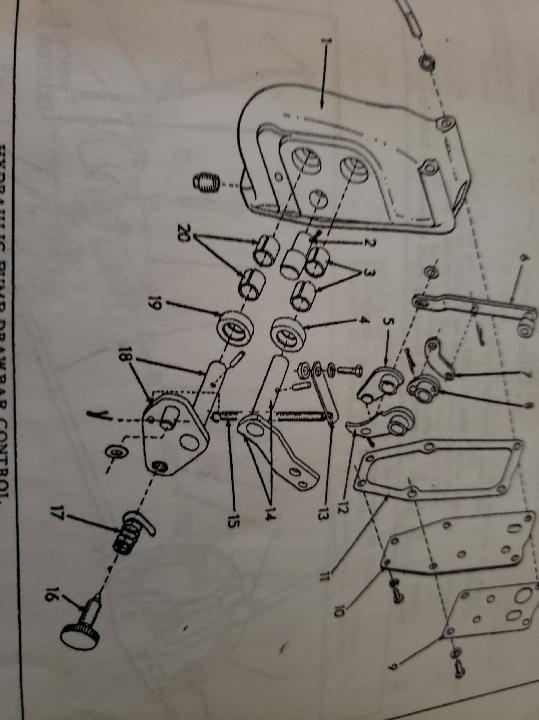

That nub I highlighted earlier is on plate #18, the book shows a spring (#13) going to an arm.

#13:

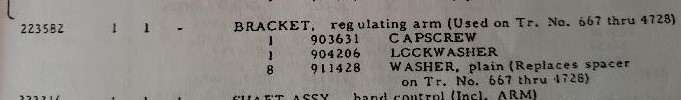

My tractor is No. 55,681, and that arm/spring is specifically listed as No's 667 thru 4728. There is no alternate arm/spring/bracket/rod/linkage/etc listed for my tractor.

I'm fairly confident that I took nothing off that nub, and certain that I have no leftover parts. I'm leaving open the possibility that something broke, fell off, and I never saw it....but I don't know what that would look like, what it would be, where it would connect, and it's not in the book. If any of you could help me with that, I would appreciate it. If you're just going to keep throwing "TB linkage" at me, that doesn't help.

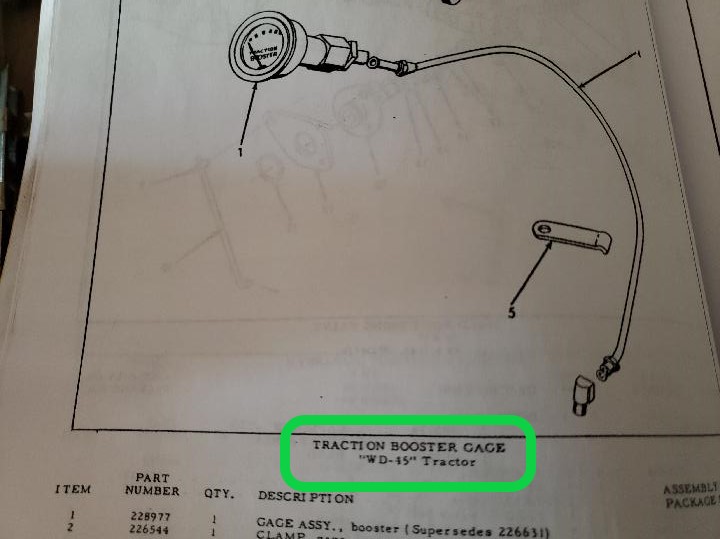

p.s. The next page shows a TB gage (sic), listed as 45-only. FWIW. I don't know better, that's why I bought the book.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8617

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 10:48am Posted: 20 May 2020 at 10:48am |

The nub on 18 has a slotted piece (similar to a generator adjustment slide) which hooks the nub and goes rearward to the drawbar anchor. It has an adjustable end held to anchor by a bolt. The spring hooks the nub and goes "up" and hooks to the ear on hand clutch cover. When the thumb screw is screwed into pump body it locks TB function "out". That is how you want it for everything but plowing so you only need that to work TB function when drawbar drafting is used. I'll go look in agcopartsbooks.com and see if I can find it. WD's and 45's had it.

Page 244 #16 link assy,regulating,hyd pump #18 end,adjusting,regulating link go to bottom of page "view books" then type in "WD"...will give option of WD,WD45,power unit,click it then scroll down to page 244,click it. Titled "drawbar"

This should be in the info you have ....you just have to find it

Edited by SteveM C/IL - 20 May 2020 at 11:01am

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87703

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 1:08pm Posted: 20 May 2020 at 1:08pm |

|

Eric, have to tried to move the levers/ arms on the valve by hand instead of using the handle on the dash ? Make sure they go full stroke ?.......... that arm #18 has a roll pin in it... not the same, but i had a pin like that break on my "B" and was not rotating the shaft when i moved the lever... Took a while to find that.

|

|

Like them all, but love the "B"s.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 2:01pm Posted: 20 May 2020 at 2:01pm |

The traction Boost system is Allis Chalmers system for draft control. It is activated by in creased drawbar pull on the lower connection and is controlled by where the operator sets the lever on the left side of the steering post quadrant. All CA's WD's and 45s had it from the factory, whether they had a TB gauge or not. If you have the hydraulics set for hold position (see decal on battery box or in the manual), as you should for loader use, the TB linkage, whether it's connected or not, shouldn't have anything to do with the pump working. Either your pump isn't pumping or your valve isn't letting pressure thru and is dumping back to the reservoir.

Edited by CTuckerNWIL - 20 May 2020 at 2:02pm

|

|

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 2:08pm Posted: 20 May 2020 at 2:08pm |

@ steve(ill), yes, when I had everything off the tractor I rotated all the externals to make sure the internals actuated. When I throw the lever it appears that everything moves full.

@ SteveM C/IL, thank you! Off the top of my head, I have none of that linkage, and now I know what you're referring to. Guarantee it wasn't there when I pulled the hydo pump, and I don't remember anything like that when I was working around the drawbar, but like I said it's possible I just never saw it. I'll look a the tractor & dig through the books tonight to see what I can find. That at least points me in a direction to chase down, it's very much appreciated.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 10:01pm Posted: 20 May 2020 at 10:01pm |

...but as Charlie says,that linkage has no effect on pump working or not. The way it works is you loosen thumb screw form body then when the draft pulls drawbar or snap coupled implement rearward,that linkage follows and pulls nub on #18 which activates internal control in pump causing it to apply pressure to the 3 ports in the hold valve. Simple and works well. When TB is not in use,the thumb screw is to be locked into the body.

Pretty sure the #12 lever was redesigned when the 45's came out to keep implements in the ground.

Edited by SteveM C/IL - 20 May 2020 at 10:08pm

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 10:03pm Posted: 20 May 2020 at 10:03pm |

|

Like CtuckerNWIL said, if adjusted for hold the link does not matter.

I would take pump back apart and recheck ever thing again. There is a pin in TB section that wares off some times.

Hope you find the problem. We'll keep trying to help. MACk

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 10:09pm Posted: 20 May 2020 at 10:09pm |

SteveM C/IL wrote: SteveM C/IL wrote:

...but as Charlie says,that linkage has no effect on pump working or not. |

Well crap, I missed seeing CTuckerNWIL's reply, it must've come in while I was typing. I'm not plowing, so chasing Traction Boost is moot. As much as I don't want to, I'll tear back into the pump. Thanks for all the info, guys.

|

|

john(MI)

Orange Level

Joined: 12 Sep 2009

Location: SE MI

Points: 9262

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 10:27pm Posted: 20 May 2020 at 10:27pm |

|

Nothing to do with your problem, but on my WD I had one line coming from the pump with a quick disconnect fitting. On the 2 cylinders for the rear lift and the 2 on the loader I had them tee'd with a quick disconnect. I would just switch the fitting to whichever one I wanted to use. If I wasn't using the loader I would raise it up and put a couple pieces of angle iron on the cylinders, lower it on to them and then switch the fitting. I have also seen people use a long bar across the front end and lower the loader on to it. I never tried that way.

|

|

D14, D17, 5020, 612H, CASE 446

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2020 at 10:23am Posted: 21 May 2020 at 10:23am |

|

When you get it apart,carefully inspect the pins through the levers in that back housing. It almost sounds like something in there is not connected anymore. There are pins on levers inside there that may have failed as well. Take your time and study it. After a while it starts making sense how it all works.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2020 at 10:49am Posted: 27 May 2020 at 10:49am |

|

Did you ever get this figured out?

|

|

MotoErik

Bronze Level

Joined: 28 Oct 2012

Location: West-Central MN

Points: 11

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Sep 2020 at 6:04pm Posted: 20 Sep 2020 at 6:04pm |

|

Sorry for the delay, I've been having some health issues, the tractor has been sitting untouched. I hope to get it up and running before winter, I really need it for snow removal, so I should be tackling it pretty soon?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

, which wouldn't apply. You surely are talking about something else?

, which wouldn't apply. You surely are talking about something else?

SteveM C/IL wrote:

SteveM C/IL wrote: