| Author |

Topic Search Topic Search  Topic Options Topic Options

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7060 Pto seals replacement again. Topic: 7060 Pto seals replacement again.

Posted: 14 Dec 2019 at 9:03pm |

|

Got a couple of questions on replacing the seals on my PTO, how much torque should I put on the big nut of the shaft? first time I replaced it I had a Issue where the 1000 shaft actually rubbed on the output shaft when using the pto on 540 and got hot enough to actually damage the front seal and cause a leak again before the problem was noticed, which made me wonder if this problem could have been caused by not having enough torque on the nut? or any other idea as to why this would happen? taking it apart all the bearings and gears look to be fine and did not have any unusual wear or other signs of improper install.

|

|

|

Sponsored Links

|

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Dec 2019 at 10:36pm Posted: 14 Dec 2019 at 10:36pm |

Here is a picture from previous post I did on a dual pto install. Manual says to tighten that nut 20 inch pounds more than turning torque. Mine checked out at 185 inch pounds turning, so I tightened it down until it went to 205 to 210 inch pounds. Make sure you install the lock pin with new wire also. I would not over tighten it.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Dec 2019 at 10:37pm Posted: 14 Dec 2019 at 10:37pm |

|

It's been in there for about 200 hours. So far works great, no leaks no noise.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2019 at 8:00am Posted: 15 Dec 2019 at 8:00am |

|

Sounds like front bearing or race is the problem. Are you sure the front race is not missing? MACK

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2019 at 5:57pm Posted: 15 Dec 2019 at 5:57pm |

MACK wrote: MACK wrote:

Sounds like front bearing or race is the problem. Are you sure the front race is not missing? MACK |

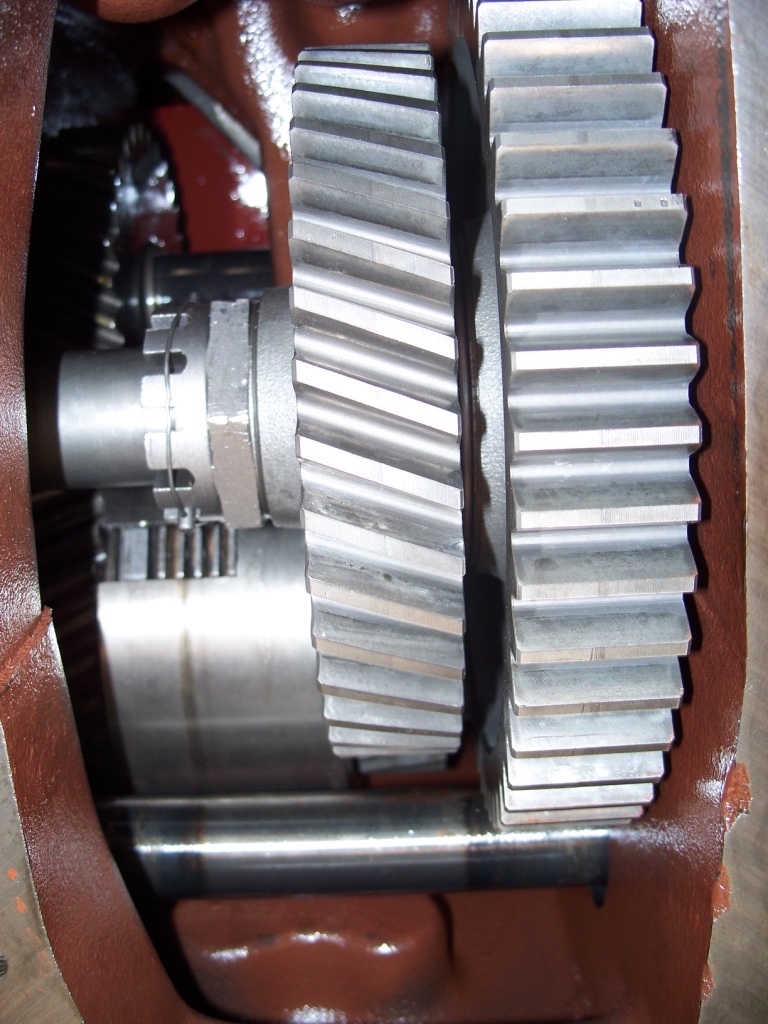

Here is a look at the hub Mack, Everything looks normal to me.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2019 at 7:36pm Posted: 15 Dec 2019 at 7:36pm |

|

It would have to be on solid shaft, not hallow shaft. MACK

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2019 at 9:04pm Posted: 15 Dec 2019 at 9:04pm |

MACK wrote: MACK wrote:

It would have to be on solid shaft, not hallow shaft. MACK |

Are you talking about the small signal bearing and race that the shaft rides on?

|

|

Dave H (NE)

Silver Level

Joined: 11 Sep 2009

Location: Western NE

Points: 288

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2019 at 9:16pm Posted: 15 Dec 2019 at 9:16pm |

|

yes that is the one Mack is talking about

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Dec 2019 at 7:15am Posted: 16 Dec 2019 at 7:15am |

|

Yes, the bearing on the front end of the longest shaft. MACk

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Dec 2019 at 7:42pm Posted: 16 Dec 2019 at 7:42pm |

MACK wrote: MACK wrote:

Yes, the bearing on the front end of the longest shaft. MACk |

Bearing looks fine and race looks to be correct.

Was wondering if it would be wise to re use the old big seal that I just installed this spring? Or should I just bite the bullet and replace it again? looks fine, but it is $50 through Agco.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Dec 2019 at 10:31pm Posted: 16 Dec 2019 at 10:31pm |

|

There is a torrington bearing between the 2 gears, is that still good and the washer also?

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Dec 2019 at 8:57am Posted: 17 Dec 2019 at 8:57am |

LB0442 wrote: LB0442 wrote:

There is a torrington bearing between the 2 gears, is that still good and the washer also? |

Appreciate the pictures and yes they are both there and in good condition.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Dec 2019 at 9:22am Posted: 17 Dec 2019 at 9:22am |

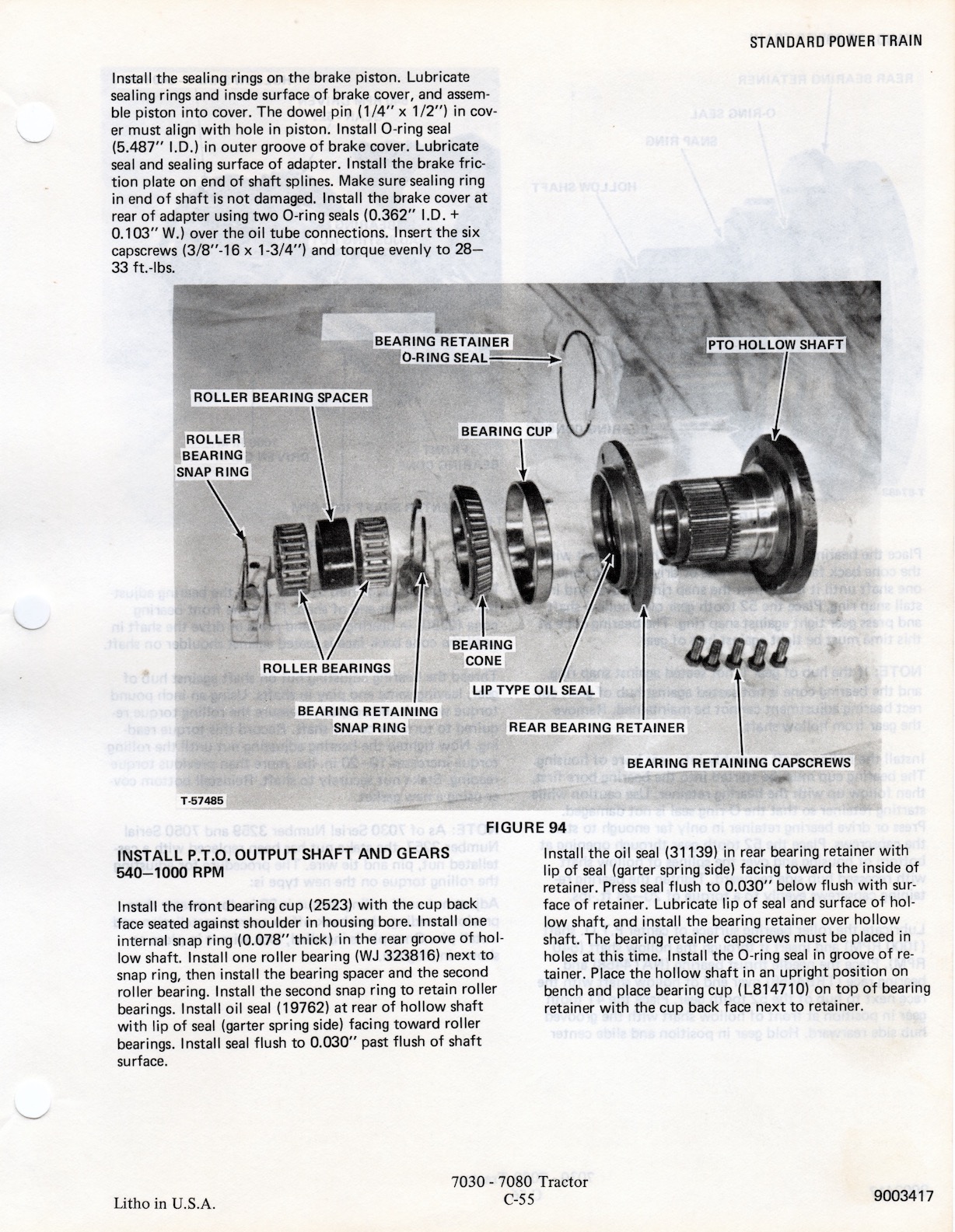

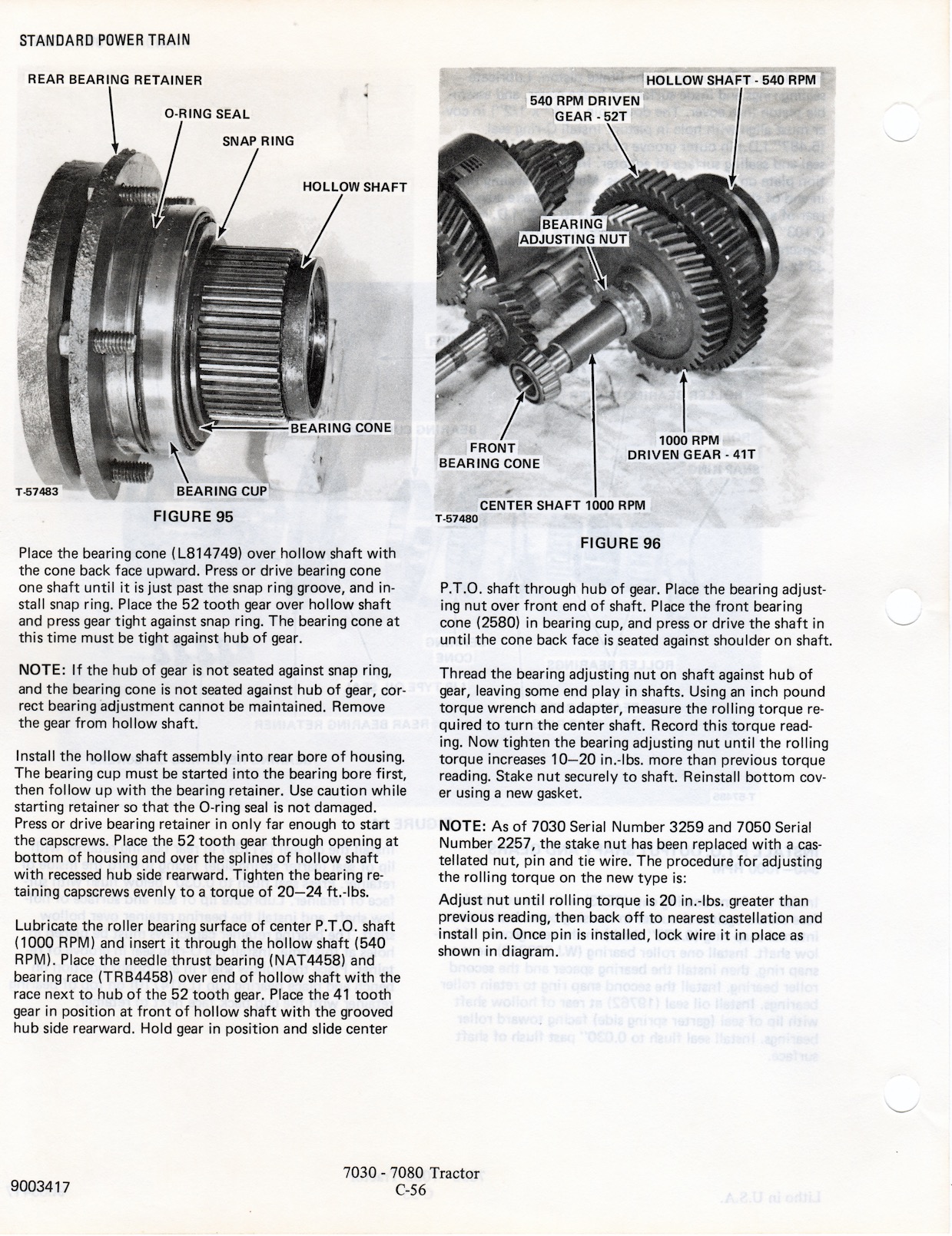

Well here are the install pages from the manual possibly that will help.

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Dec 2019 at 8:02pm Posted: 17 Dec 2019 at 8:02pm |

LB0442 wrote: LB0442 wrote:

There is a torrington bearing between the 2 gears, is that still good and the washer also? |

appreciate your time in posting this, very helpful, way better then my shop manual for some reason, I think my issue was that I might not have got the shaft in far enough in on the front bearing, going to be very mindful of the shaft protrusion this time.

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2019 at 7:39pm Posted: 18 Dec 2019 at 7:39pm |

LB0442 wrote: LB0442 wrote:

It's been in there for about 200 hours. So far works great, no leaks no noise. |

How exactly did you measure the torque on the nut? PTO output shaft with a socket?

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2019 at 8:46pm Posted: 18 Dec 2019 at 8:46pm |

|

Yes, I can't remember what size socket but one fit on the PTO shaft. I have a couple of different torque wrenches but the dial type ones work best for that. Similar procedure to installing differential pinion bearings.

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2019 at 9:27pm Posted: 18 Dec 2019 at 9:27pm |

LB0442 wrote: LB0442 wrote:

Yes, I can't remember what size socket but one fit on the PTO shaft. I have a couple of different torque wrenches but the dial type ones work best for that. Similar procedure to installing differential pinion bearings. |

I think my issue may have been improper torque on the nut, as I tightened the nut the 1000 shaft became flush with the hollow shaft as it should.

|

|

AC 426 power

Orange Level Access

Joined: 01 May 2012

Location: Ohio

Points: 530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Dec 2019 at 12:28am Posted: 21 Dec 2019 at 12:28am |

|

Success! Got it all back together and no leaks or notices and most importantly no contact with the 1000 shaft, ran the grain cart all day with no issues.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

MACK wrote:

MACK wrote: