| Author |

Topic Search Topic Search  Topic Options Topic Options

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: How to bend exhaust tubing? Topic: How to bend exhaust tubing?

Posted: 03 May 2017 at 11:46am |

I have an old undershot muffler off the 8N, and I want to put a bend in it so I can convert it to vertical (so I can run a All-Crop with it). How do I go about doing this? I tried it once before, and even while being very careful with low heat, it developed a hole in the pipe. Anyone ever bend exhaust tubing and have a good method?

Thanks!

|

|

|

Sponsored Links

|

|

|

Dans 7080

Orange Level

Joined: 05 Feb 2010

Points: 1146

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 12:05pm Posted: 03 May 2017 at 12:05pm |

|

Exhaust pipe bender I the only way. It would be easier to buy the bends and weld or clamp them together.

|

|

When someone tells you Nothings Impossible, Tell them to slam a revolving door

|

|

farmboy520

Orange Level Access

Joined: 22 Jun 2016

Location: Beason, IL

Points: 553

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 12:09pm Posted: 03 May 2017 at 12:09pm |

|

I would go to your local exhaust shop and ask them how much they would charge for them to make the bends for you.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87905

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 12:10pm Posted: 03 May 2017 at 12:10pm |

|

that's what I do.. buy a 90 degree elbow and wire feed weld it as needed.

|

|

Like them all, but love the "B"s.

|

|

Michael V (NM)

Orange Level Access

Joined: 12 Sep 2009

Location: NM

Points: 2472

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 12:40pm Posted: 03 May 2017 at 12:40pm |

|

$33.00 from ASAP, PN 100567 ....

really ought to find ya a WD,,theres lots of them around and usually don't go for much...

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 1:29pm Posted: 03 May 2017 at 1:29pm |

easier to get a orange tractor and be done with the N

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 1:42pm Posted: 03 May 2017 at 1:42pm |

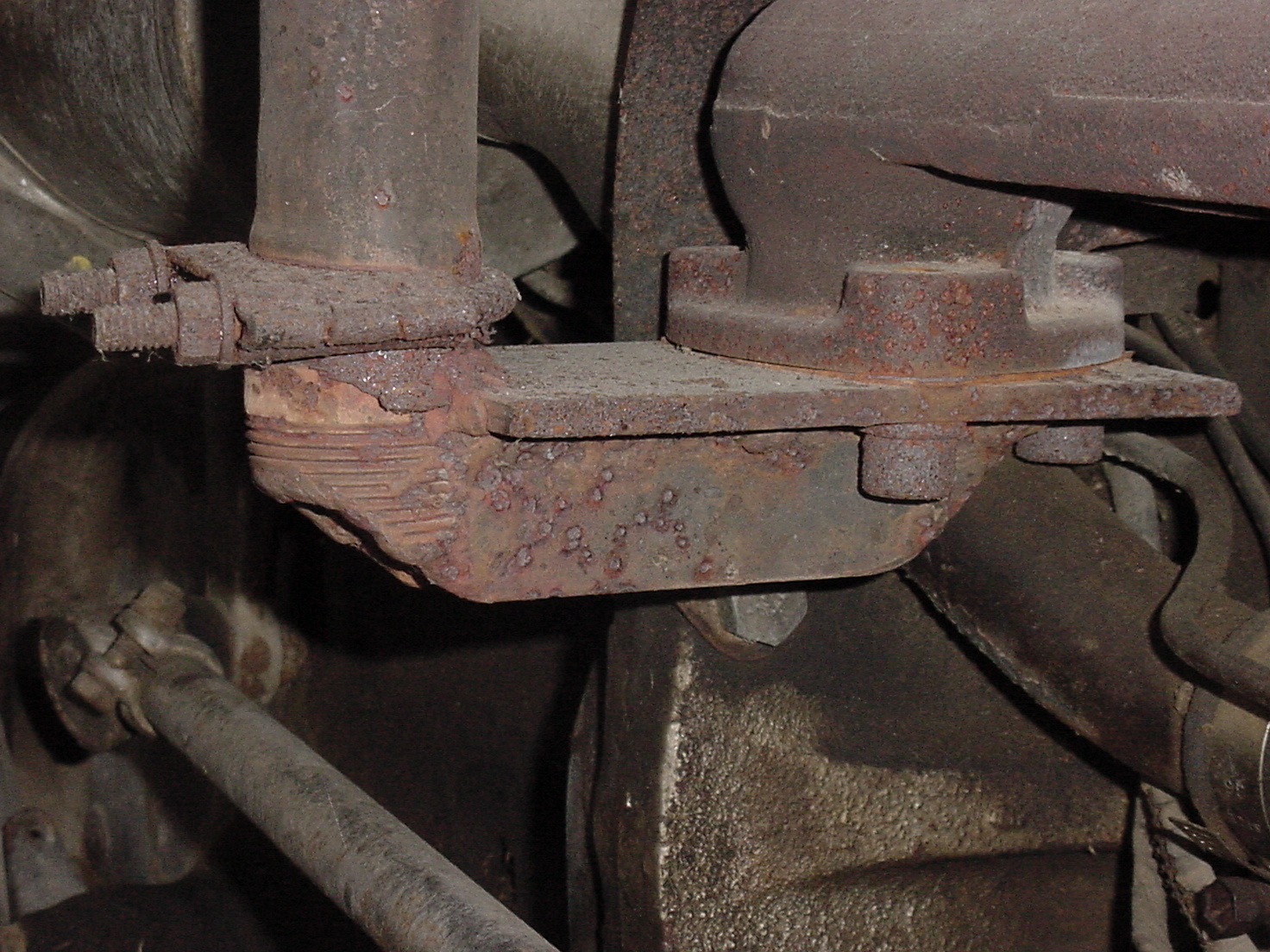

In my 2015 ASAP catalog there are several options including 100567 which is the bent pipe, a brace, and the muffler. or really a muffler with bent pipe. I'm not sure the bent pipe is strong enough, from my experience the pipe and the upright muffler will get bent hitting tree limbs and maybe tall corn. I made an assembly for my MF-135 decades ago because I didn't think it was a good idea for the low mounted muffler to be leaving corn stalks glowing while plowing standing stalks. Looks plenty rusty from being on the tractor probably 20 years or more. I have bent the pipe and the muffler hitting things up top.  Gerald J.

|

|

TimNearFortWorth

Orange Level

Joined: 12 Dec 2009

Points: 2014

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 3:15pm Posted: 03 May 2017 at 3:15pm |

|

Muffler shop would make short order of that and could make you 2 or 3 pieces as a variant so you don't have to go back. We installed 60+ new tie stalls when we took out the original cement in a early 1900's built dairy barn with wooden stanchions growing up. Dad did not like the gauge of ready made stanchion materials at the time and with a little research, bought the pipe to his liking and had the local muffler shop bend them to form pretty quick.

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 4:20pm Posted: 03 May 2017 at 4:20pm |

|

On my IH 464 I took off the piece that bolted to the manifold and got a machine shop to weld a pipe nipple to it and then used black pipe to route the exhaust and put on a muffler.

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 4:31pm Posted: 03 May 2017 at 4:31pm |

|

Creston, you can fill the pipe with sand, then heat and bend it around a round object. You'll only have moderate success doing it this way though.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 4:43pm Posted: 03 May 2017 at 4:43pm |

CAL(KS) wrote: CAL(KS) wrote:

easier to get a orange tractor and be done with the N  |

Nah  An 860 is what I need!

|

|

shameless dude

Orange Level

Joined: 10 Apr 2017

Location: east NE

Points: 13607

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 9:04pm Posted: 03 May 2017 at 9:04pm |

|

what you need is a slap up side the.....lol

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 9:09pm Posted: 03 May 2017 at 9:09pm |

|

I'd rather have the "Power to keep my combine humming" Lol

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 9:26pm Posted: 03 May 2017 at 9:26pm |

CrestonM wrote: CrestonM wrote:

CAL(KS) wrote: CAL(KS) wrote:

easier to get a orange tractor and be done with the N  |

Nah  An 860 is what I need! |

Nothing like jumping out the pan into the fire(LOL)

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 9:29pm Posted: 03 May 2017 at 9:29pm |

Lol Speaking of "into the fire", note it has the undershot exhaust (In a wheat field), which seems to worry everyone nowadays lol

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8637

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 10:45pm Posted: 03 May 2017 at 10:45pm |

|

if your after function not form,you can heat inside of bend and make a wrinkle bend

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2017 at 10:52pm Posted: 03 May 2017 at 10:52pm |

SteveM C/IL wrote: SteveM C/IL wrote:

if your after function not form,you can heat inside of bend and make a wrinkle bend |

I'm after function. I might try that. I'll only use the vertical muffler for a couple days, only because the farmer who owns the field where I'm combining doesn't want the undershot muffler in his field. "Fire danger".

Edited by CrestonM - 03 May 2017 at 10:53pm

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 8:16am Posted: 04 May 2017 at 8:16am |

creston, since your moving up you might as well find one with the SOS trans then you can maximize throughput and minimize loss by keeping the combine full at all times

also you can pick up tubing bends at napa or local auto store and weld on for a few $$

Edited by CAL(KS) - 04 May 2017 at 8:17am

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 8:17am Posted: 04 May 2017 at 8:17am |

|

Lol

|

|

Tbone95

Orange Level Access

Joined: 31 Aug 2012

Location: Michigan

Points: 12186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 8:27am Posted: 04 May 2017 at 8:27am |

Correction CAL, that's POS transmission!

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 8:28am Posted: 04 May 2017 at 8:28am |

for sure LOL

At my previous mechanic job, my bosses father who still worked part time, had worked at a Ford dealership for many years and they were kind of our specialty. I usually let the old man work on them as I would do the bigger tractors, heavy equip etc. I didnt mind one bit, but we did have several SOS tractors that we repaired the trans in and he got them fixed!

Edited by CAL(KS) - 04 May 2017 at 8:34am

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24697

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 8:34am Posted: 04 May 2017 at 8:34am |

|

OK.... how about ADDING pipe to the end of the original pipe ? Something bent like a 'J' that slides onto the existing pipe and bolted to the tractor. Maybe a pipe clamp to hold it onto the tail pipe.

This way, after harvest, you can unbolt the 'extension' and hang up in barn until needed. the tractor would become 'normal' again.

Jay

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 9:42am Posted: 04 May 2017 at 9:42am |

|

The first versions of the POS transmission were really POS. Later versions SOS did work and survive. The chief engineer at Ford refused to sign off on the early versions because he thought they were junk. Cost him his job. He moved to Deere at Waterloo and was in charge of their Power Shift transmission for the 3020 and 4020 which have proven to be reliable transmissions. He worked at Deere until retirement many years later.

Gerald J.

|

|

1mathom1

Silver Level

Joined: 01 Oct 2013

Location: Oklahoma

Points: 87

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 9:43am Posted: 04 May 2017 at 9:43am |

|

If I read this right, you are wanting to put vertical exhaust on an 8n. Yesterday's tractors has the whole set up for $36 and change.

If you are wanting to go vertical at the end of the existing pipe....I got nothing. Maybe a piece of flex exhaust pipe? I did that on a yard tractor once...worked fine.

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 9:45am Posted: 04 May 2017 at 9:45am |

|

On second thought, skip the 560 and go straight to the 6000 Commander.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Tbone95

Orange Level Access

Joined: 31 Aug 2012

Location: Michigan

Points: 12186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 10:04am Posted: 04 May 2017 at 10:04am |

Gerald J. wrote: Gerald J. wrote:

The first versions of the POS transmission were really POS. Later versions SOS did work and survive. The chief engineer at Ford refused to sign off on the early versions because he thought they were junk. Cost him his job. He moved to Deere at Waterloo and was in charge of their Power Shift transmission for the 3020 and 4020 which have proven to be reliable transmissions. He worked at Deere until retirement many years later.

Gerald J.

|

Yes, I've heard that before. How new did a Ford have to be to have a good one? We had a Ford 6000 with that miserable POS transmission in it, and yes, it did fail miserably. One of many disasters with that tractor. The hydraulic system were never really right. We weren't the original owners, so I don't know if they were ever right, but assume they were OK as it rolled out the factory door. They were never right for us. The brakes had 2 modes: free and locked! Made the poor SOB on a hay wagon have some serious sea legs. The first time we went to use the 3 point, we lowered the arms, attached the brush hog, and raised the arms. About 1/2 way up, the tractor began to labor and nearly stalled. With the engine shut off for about 4 days, we could finally work the lever back and forth enough to lower the brush hog. Boy, she was a beautiful running thing when it was working ok. Loved to chop corn with it, when the sos worked right, keep the flame coming about 3 inches out of the pipe! Had a bucket seat from a chevy vega bolted onto it because the original had rusted out!

Edited by Tbone95 - 04 May 2017 at 10:05am

|

|

Tbone95

Orange Level Access

Joined: 31 Aug 2012

Location: Michigan

Points: 12186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 10:12am Posted: 04 May 2017 at 10:12am |

|

Looking at pictures, I'm pretty sure ours was the "commander" type, and I remember the 2 different engine RPM with the PTO markings....but I can't say for sure and don't know what year it was.

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3915

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 10:14am Posted: 04 May 2017 at 10:14am |

|

8,9,2, has a bevaled flange on the manifold and you can buy all of the exhaust pipes for them cheap so i think if it was me i would buy a 2 new manifold clamps 1 to repalce the one you cut off and one when you put it back to normal get a new header pipe muffler and tail pipe.then you will have a nice quit tight system when you put it back. now take the old header pipe to the muffler shop or a place that bend hyd.tubing because there benders wont wrinkle the tube, bend a 180 by the flange then weld a piece of 10ga. in center of the radius to keep it from bending then a strap over to a head bolt, muffler on top with a turn out pointed forward

|

|

allischalmerguy

Orange Level

Joined: 11 Sep 2009

Location: Deep River, IA

Points: 2893

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 10:39pm Posted: 04 May 2017 at 10:39pm |

Neat story Gerald. Thanks! Pastor Mike

Gerald J. wrote: Gerald J. wrote:

The first versions of the POS transmission were really POS. Later versions SOS did work and survive. The chief engineer at Ford refused to sign off on the early versions because he thought they were junk. Cost him his job. He moved to Deere at Waterloo and was in charge of their Power Shift transmission for the 3020 and 4020 which have proven to be reliable transmissions. He worked at Deere until retirement many years later.

Gerald J.

|

|

|

It is great being a disciple of Jesus! 1950 WD, 1957 D17...retired in Iowa,

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2017 at 10:45pm Posted: 04 May 2017 at 10:45pm |

1mathom1 wrote: 1mathom1 wrote:

If I read this right, you are wanting to put vertical exhaust on an 8n. Yesterday's tractors has the whole set up for $36 and change.

If you are wanting to go vertical at the end of the existing pipe....I got nothing. Maybe a piece of flex exhaust pipe? I did that on a yard tractor once...worked fine. |

I need something that hooks straight to the manifold, as I'm trying to get away from the undershot muffler to satisfy the farmer who owns the wheat field where I'll be cutting. I might end up just buying a kit. I found a straight pipe kit for twenty something dollars at ASAP, and I figure if I put a 45 degree elbow on top and point it away, it won't bother me too much. It's only for a few days a year, anyway.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

CAL(KS) wrote:

CAL(KS) wrote: