| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: B Engine Cylinder Head Performance Topic: B Engine Cylinder Head Performance

Posted: 13 Jun 2016 at 5:02pm |

Hello gentlemen, ladies. First I would like to say that I am not pulling with my tractor, but I would like to share and ask questions about performance concerning just the model B (125ci) engine.

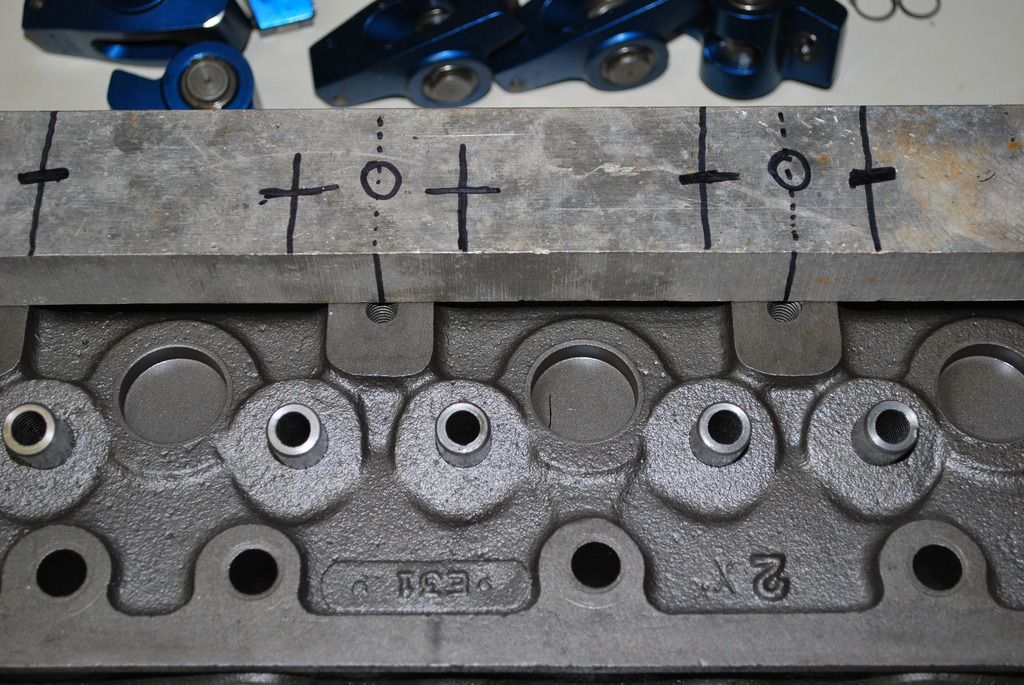

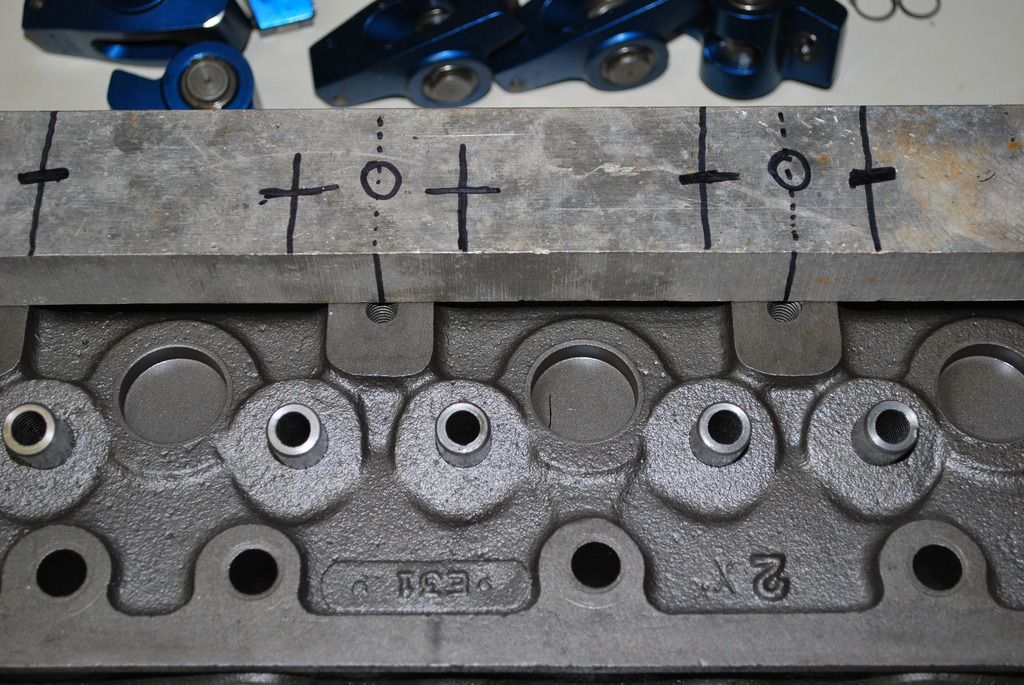

I removed the cylinder head off my engine, removed the valves and guides, pressure washed it and inspected it. There was substantial corrosion in the runners and valve pockets. I spent roughly six hours shaping and blending the runners and pocket areas to both remove the damage and smooth-blend below the valve seats and reduce the radii of the split intake "Y". Before doing a final smoothing/blending I took the head in to have .150 skimmed off the surface.

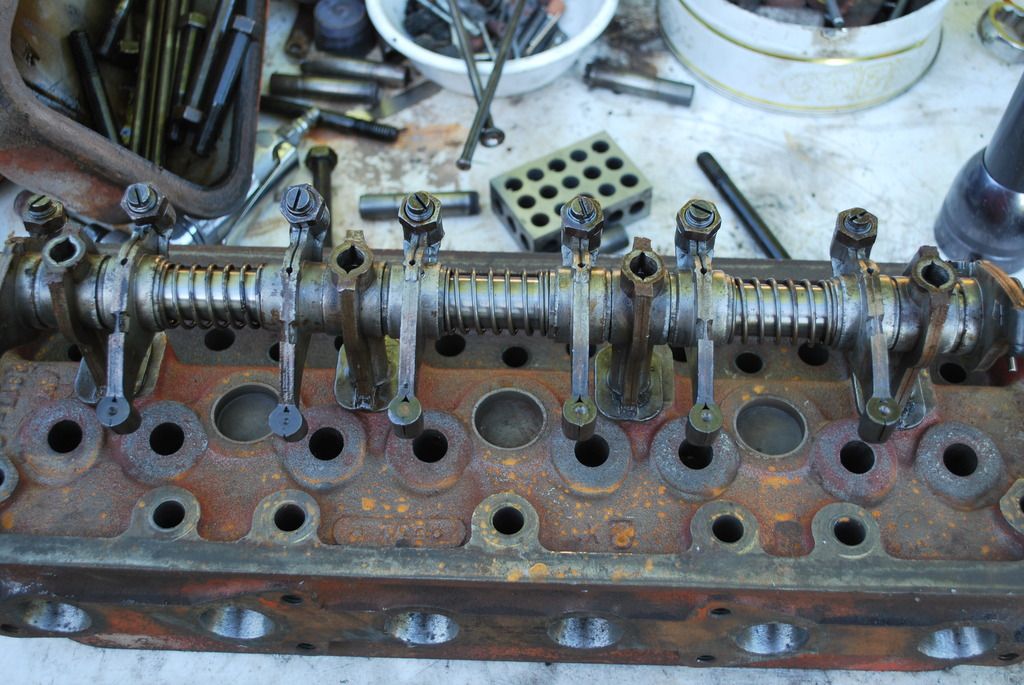

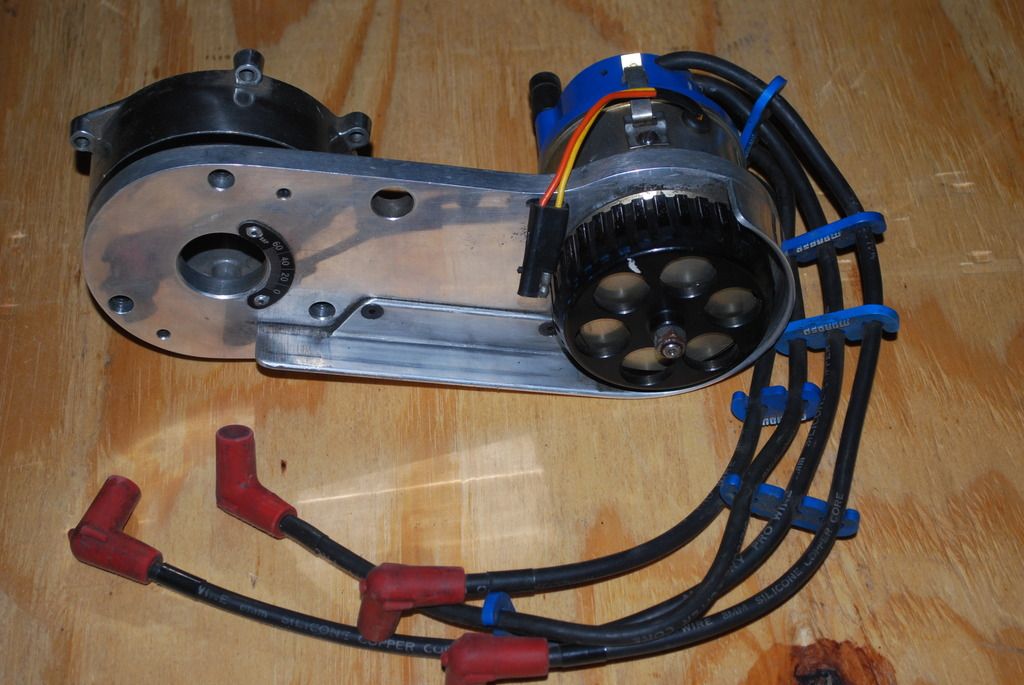

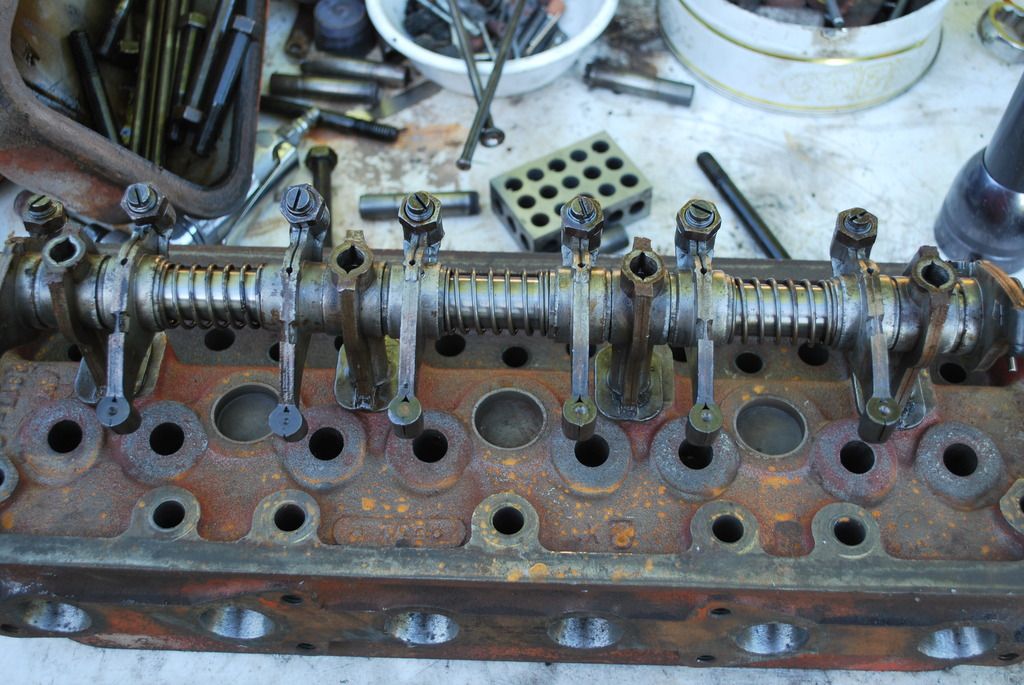

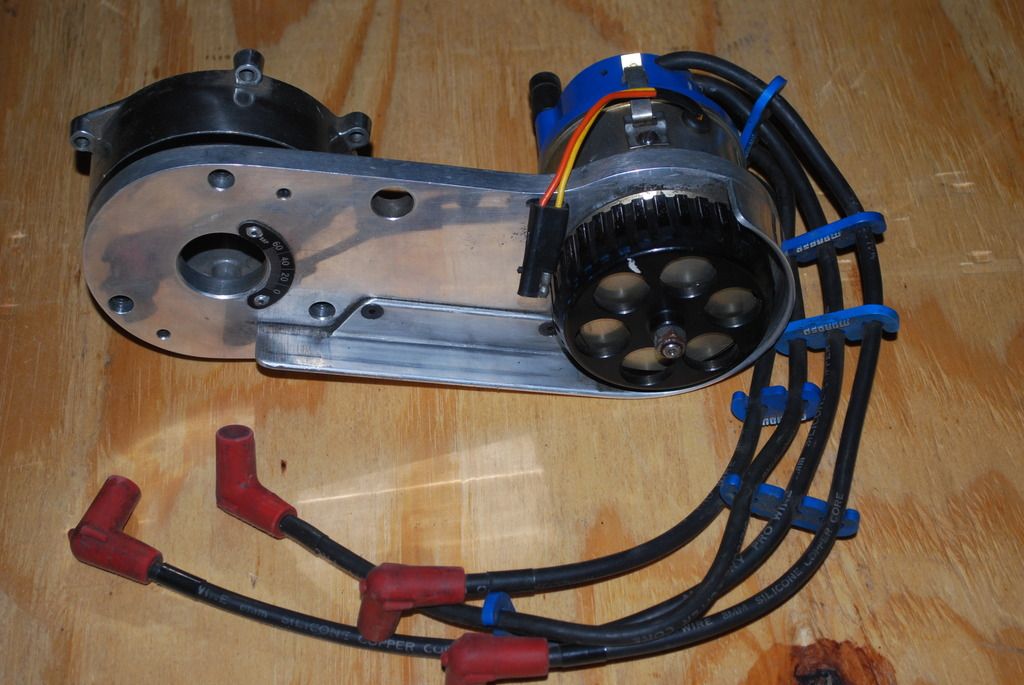

Looking at the factory rocker arm assy I can see room for improvement. First I measured a stock rocker to get an idea of the ratio. Center of shaft to center of valve stem 1.95 and center of shaft to center of pushrod 1.30. Divide 1.95 by 1.30 equals 1.5 ratio. This was just an "eyeball" measurement but it's what I am going to go by.  " border=""> " border="">

|

|

|

Sponsored Links

|

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2016 at 5:07pm Posted: 13 Jun 2016 at 5:07pm |

" border="">

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2016 at 5:09pm Posted: 13 Jun 2016 at 5:09pm |

" border="">

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2016 at 5:11pm Posted: 13 Jun 2016 at 5:11pm |

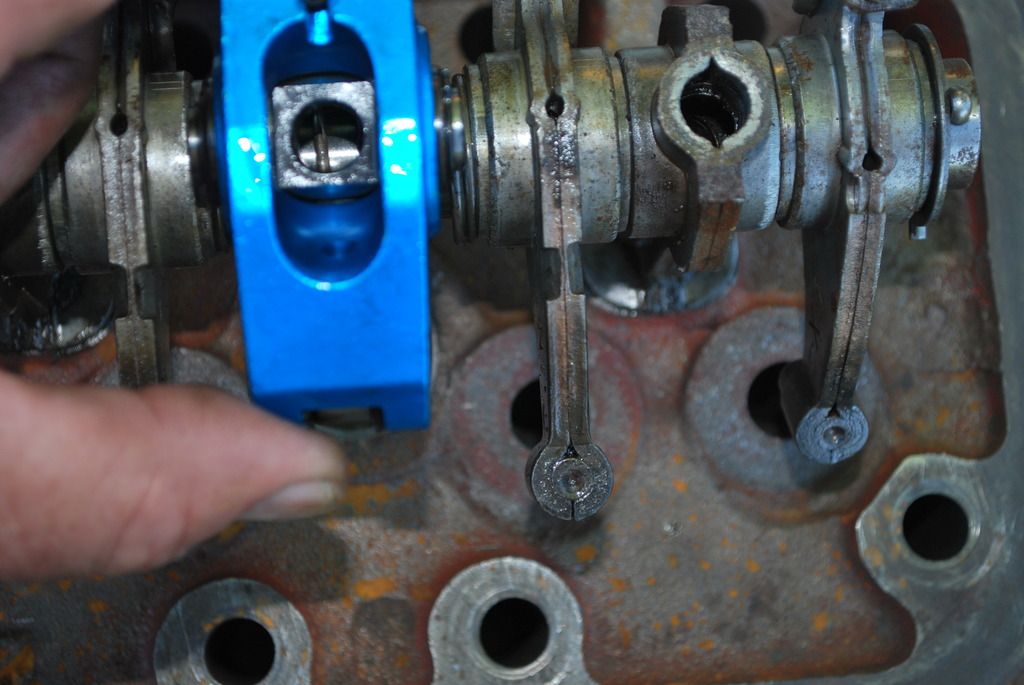

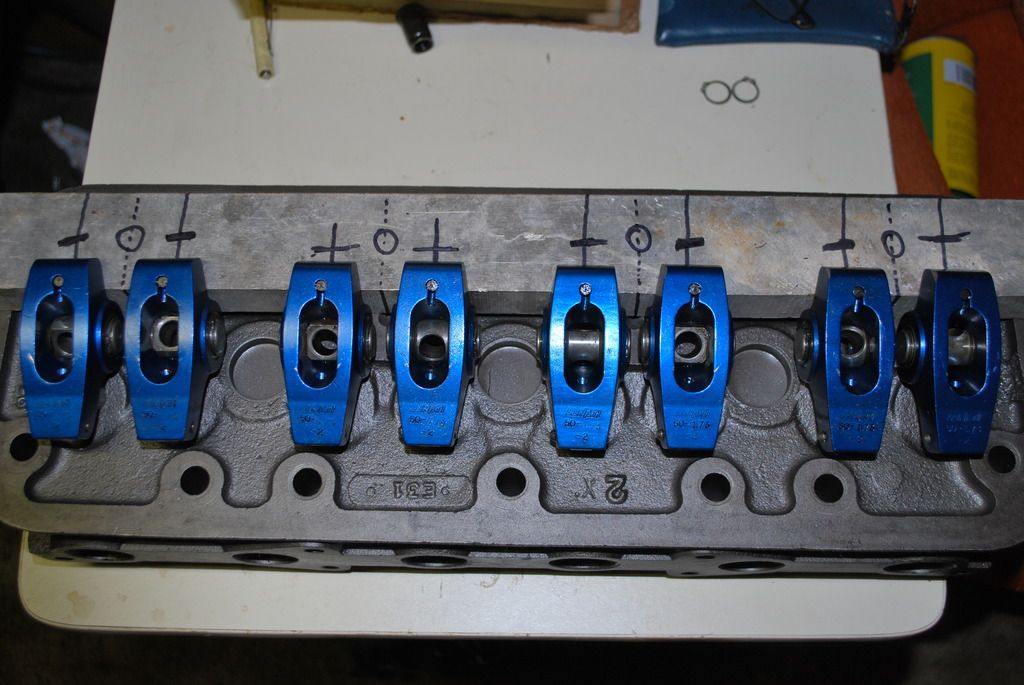

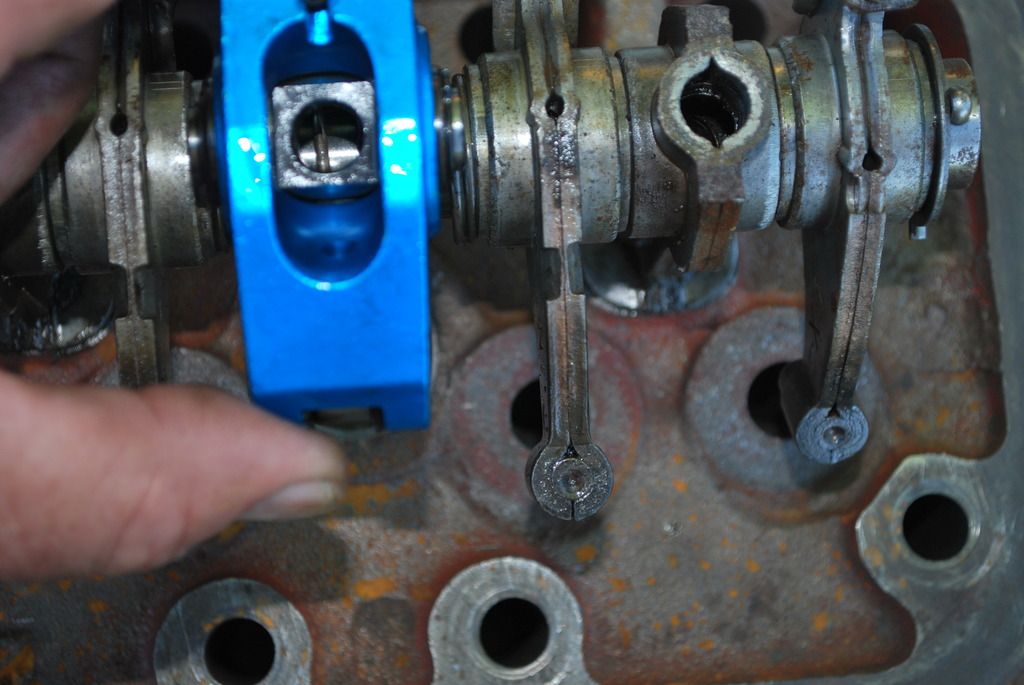

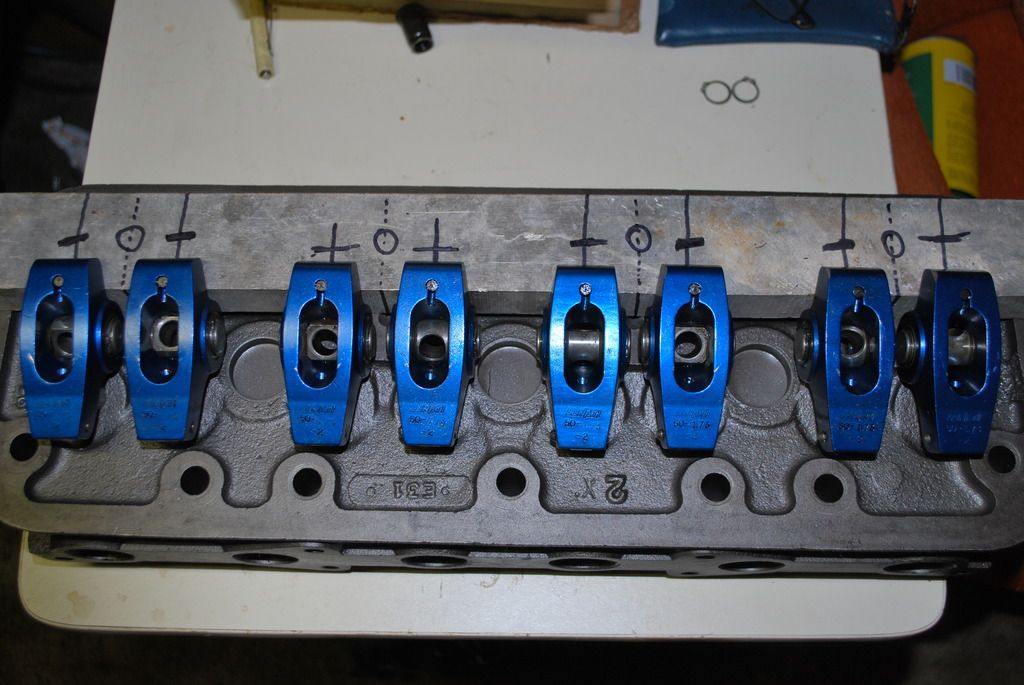

This is a 1.6 roller rocker, I have some spare BB 1.73 Lunati's that may be better to work with.  " border="">

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2016 at 5:13pm Posted: 13 Jun 2016 at 5:13pm |

" border="">

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2016 at 5:16pm Posted: 13 Jun 2016 at 5:16pm |

This tray was under the rocker arm assy. Seems like it would prevent oil from dripping on the lifters & camshaft...maybe?  " border="">

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5191

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 7:27am Posted: 14 Jun 2016 at 7:27am |

|

The "tray" was used to keep oil away from the valve guides before stem seals were generally accepted.

If you're not looking for added performance for pulling, what is the need for the trick parts, porting and taking .150" off of the surface?

Many of these engines have run for many decades in factory form and most will out live many of use just as they were built.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 10:41am Posted: 14 Jun 2016 at 10:41am |

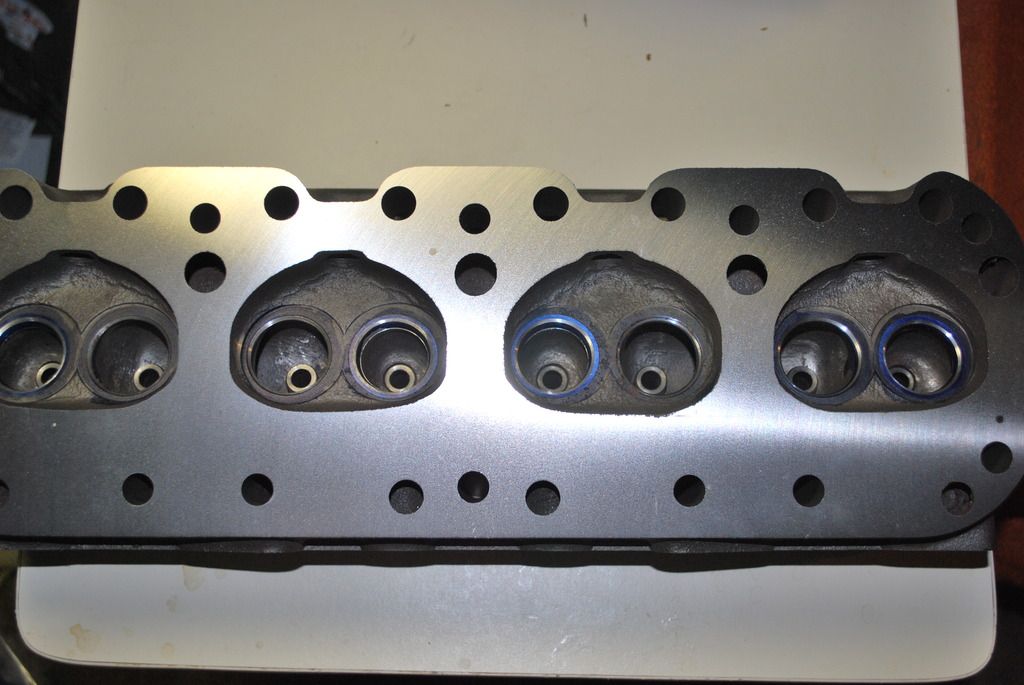

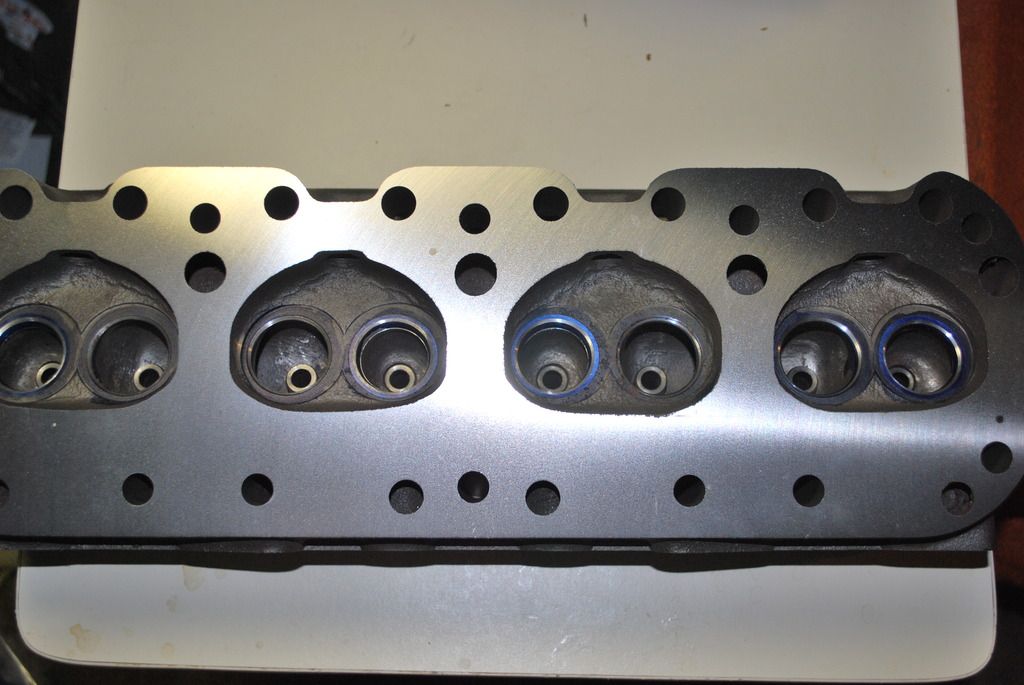

Thanks Paul, I wasn't sure why that tray was used. Shop finally called to say my cylinder head was finished. They media-blasted it first, installed the guides I supplied, installed hardened exhaust seats, cut the valve seat angles on a Serti machine. Lastly they milled the surface of the head .150.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 8:49pm

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 10:46am Posted: 14 Jun 2016 at 10:46am |

Paul happens to be running a turbo CA

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 10:59am Posted: 14 Jun 2016 at 10:59am |

This picture is a give-away to how far the head was milled.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 8:54pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 11:01am Posted: 14 Jun 2016 at 11:01am |

Looks like a new head.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 8:56pm

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 11:04am Posted: 14 Jun 2016 at 11:04am |

happen to have 2 kz 1000's sitting at dads place :)

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 11:04am Posted: 14 Jun 2016 at 11:04am |

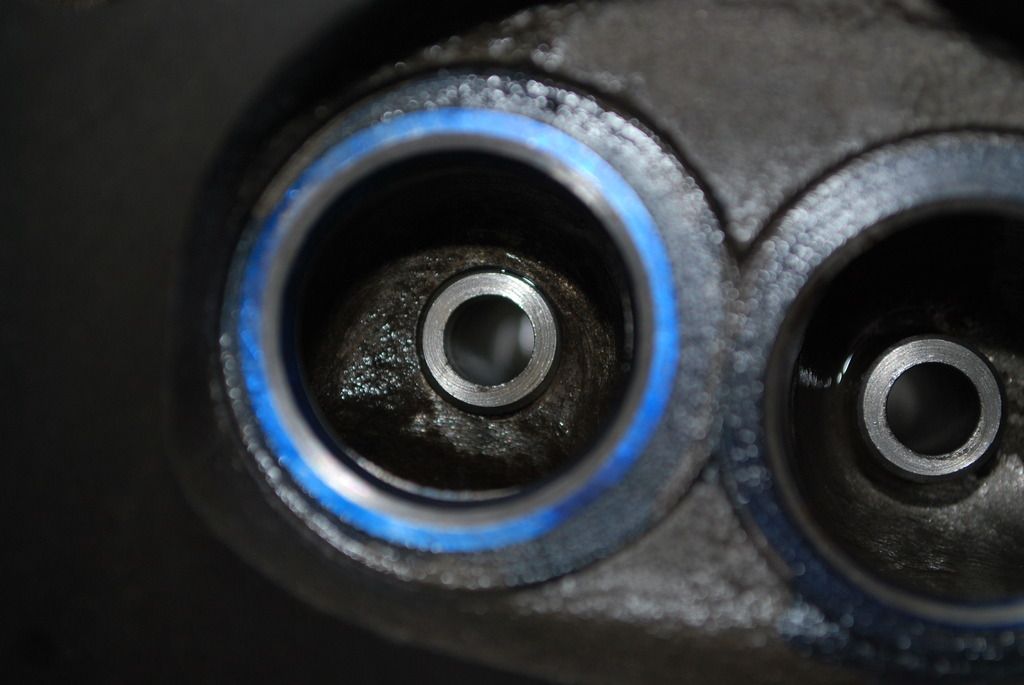

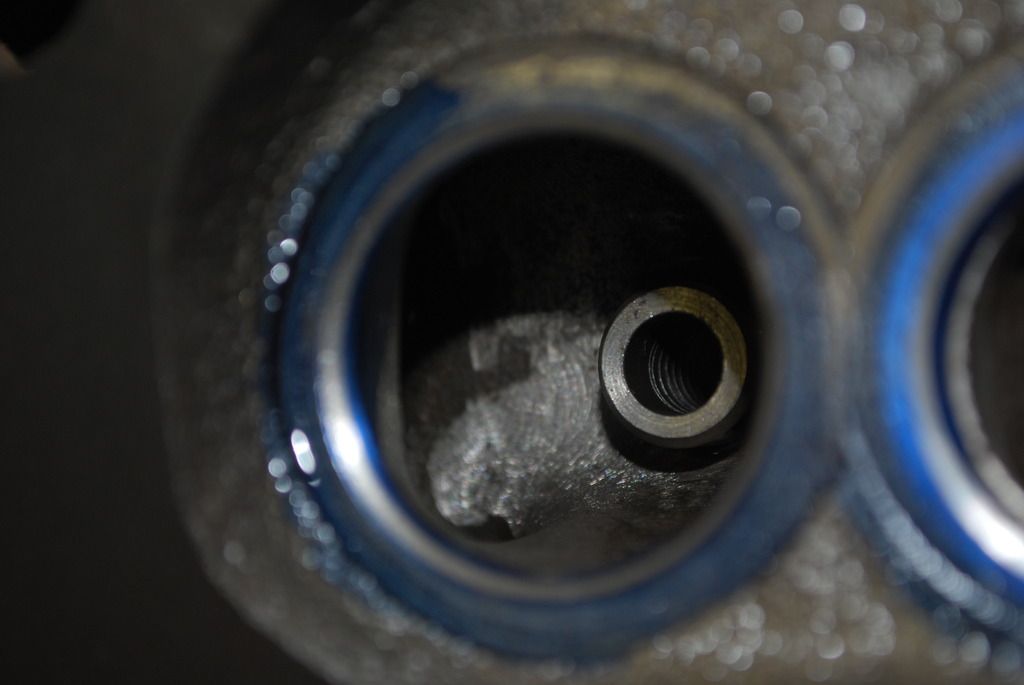

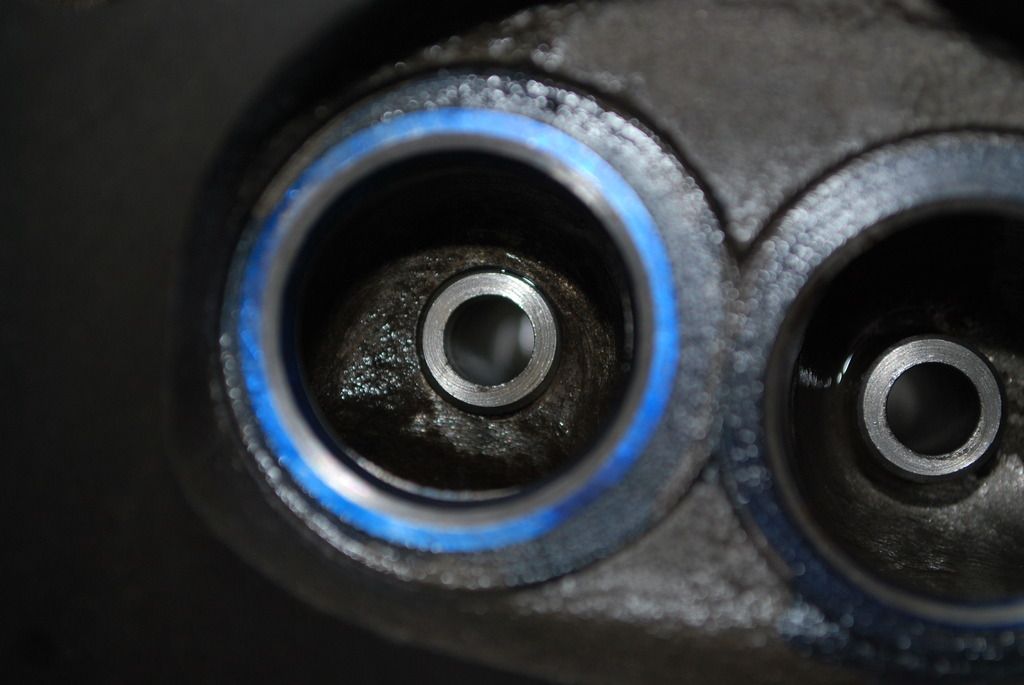

Two of the exhaust seats were pitted deep enough that seats had to be installed. The shop owner said to just do all the exhausts and it will be unleaded gas friendly, never have to worry about seats wearing out again.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 9:03pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 11:14am Posted: 14 Jun 2016 at 11:14am |

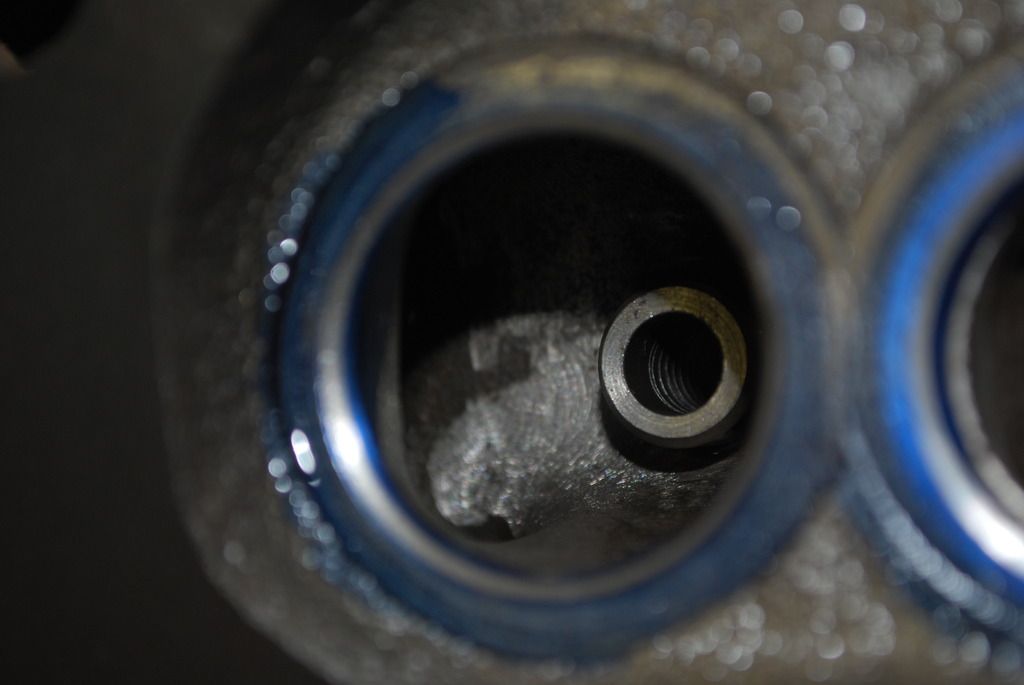

I may retake these pictures with a different camera/lens. It's difficult to show the bowl porting. I spent a leisure 6 hours smoothing and blending the bowls to the runners. Not necessarily for performance because this engine has had water in it over a long periods of time. The piston domes of 1 and 2 are extremely bad and all of the sleeves will note hone out (pitting) Anyway I basically blended all the exhaust bowls and runners to match. I did a little at a time. After I removed so much on the 1st bad port, I would move to the next and so on until they were all equal (feeling with my calibrated index finger).  " border="">

Edited by Ryan59 - 23 Jun 2016 at 9:30pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 11:15am Posted: 14 Jun 2016 at 11:15am |

This belt-drive magneto would work with any 4-cylinder or V8 engine. Make a bracket to hold it in place and go.  " border="">

Edited by Ryan59 - 16 Jun 2016 at 3:19pm

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 11:30am Posted: 14 Jun 2016 at 11:30am |

|

my dad bought one new in 78 and still has it. bout 17k miles on it now. he got another one a couple of years ago so one of us boys could ride with him. its usually my brother who has no kids

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 2:55pm Posted: 14 Jun 2016 at 2:55pm |

Before pressure washing this head it needs a little clean-up porting with sand-paper rolls. More or less to radius sharp edges, nothing real important.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 9:37pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 2:58pm Posted: 14 Jun 2016 at 2:58pm |

Hard to focus on the inside of these bowls to show how conservative I ported these.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 9:40pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 3:01pm Posted: 14 Jun 2016 at 3:01pm |

One thing I did "open up" was the "Y" split area where the intake runners divide. I decided not to build-up the back-side wall of this split port with epoxy as described by a knowledgeable and highly respected person on this forum. I had to remind myself that I'm not going for the level of performance that his engine is built.  " border="">

Edited by Ryan59 - 23 Jun 2016 at 9:48pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 3:03pm Posted: 14 Jun 2016 at 3:03pm |

I can make this conversion plate relatively easy but as some of you may already know the push-rod holes would need to be off-set. Before I get to far along could one of the modification oriented person's step in and advise.  " border="">

Edited by Ryan59 - 24 Jun 2016 at 9:16pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 3:06pm Posted: 14 Jun 2016 at 3:06pm |

I bought these 1.73, 7/16 stud Lunati's 19 years ago and would like to attempt to use them if at all possible. From the center of the push-rod to the center of the valve stem roller that are 1" shorter in length that the stock stamped steel & spot welded arms.  " border="">

Edited by Ryan59 - 24 Jun 2016 at 9:22pm

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 3:17pm Posted: 14 Jun 2016 at 3:17pm |

I can drill and tap these Lunati's for the adjustment screw.  " border="">

Edited by Ryan59 - 24 Jun 2016 at 9:25pm

|

|

patrickmull

Orange Level

Joined: 11 Jan 2011

Location: Casey IL

Points: 893

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 7:15pm Posted: 14 Jun 2016 at 7:15pm |

|

what is that distributor off of

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2016 at 9:09pm Posted: 14 Jun 2016 at 9:09pm |

|

With a blue cap? It's a Vertex magneto. It's off a Kawasaki KZ1000 drag bike.

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2016 at 11:05pm Posted: 15 Jun 2016 at 11:05pm |

|

Apparently this topic has become "look at my foreign motorbikes" instead of "B cylinder head performance"

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

NEVER green

Orange Level Access

Joined: 28 Feb 2013

Location: MN.

Points: 8959

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2016 at 11:12am Posted: 16 Jun 2016 at 11:12am |

Alex09(WI) wrote: Alex09(WI) wrote:

Apparently this topic has become "look at my foreign motorbikes" instead of "B cylinder head performance"

|

SO???!!! Performance is bilingual.

|

|

2-8050 1-7080 6080 D-19 modelE & A 7040 R50

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2016 at 2:53pm Posted: 16 Jun 2016 at 2:53pm |

If you are thinking the pictures are taking up band width you are wrong.

They are simply linked to my photobucket account. They can go away as

quickly as they appeared. As my cylinder head work progresses I

will clear the motorcycle pics. Parts should have arrived Monday but YT

said they are behind getting orders out. Head has been in the shop

waiting..... This was my daily rider, 2010 FXDWG bought new. Had to sell when I retired.  " border="">

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2016 at 3:04pm Posted: 16 Jun 2016 at 3:04pm |

|

That magneto would work on any 4-cylinder and V8 engines as well. Vertex makes a cap for dual-plug 4-cylinder heads. On a V8 the second wire would connect to a cylinder on the exhaust stroke. So 1-4-6-7 fire on the compression stroke and 8-3-5-2 fir on the exhaust stroke for that 720 degrees. Crank trigger ignitions use (or can use) 4 coils with dual plug wires coming out. As far as the crank trigger is concerned it's bolted to a 4-cylinder engine.

This is the kind of information that is universal.

|

|

patrickmull

Orange Level

Joined: 11 Jan 2011

Location: Casey IL

Points: 893

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2016 at 4:39pm Posted: 16 Jun 2016 at 4:39pm |

|

it looked like it could be used on my pulling tractor

|

|

Ryan59

Silver Level

Joined: 30 May 2016

Location: Kansas

Points: 68

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2016 at 6:35pm Posted: 16 Jun 2016 at 6:35pm |

|

And it would. If you had a front engine plate, it could mount on there backwards so the cap faces the engine & wires would be where they should be. The belt would be in front and be driven off the crank. The governor would still control the carburetor arm. Just put a block-off plate on the back side to keep oil in.

Looking at the mag off this tractor it doesn't have any advance/retard either so this wouldn't be any different. Set it at what? 20 degrees crankshaft? For stock governor.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Alex09(WI) wrote:

Alex09(WI) wrote: