| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Gary.IL

Bronze Level

Joined: 11 Dec 2021

Location: Quincy, IL

Points: 13

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D17 Rear Main Seals Topic: D17 Rear Main Seals

Posted: 20 Jan 2022 at 5:35pm |

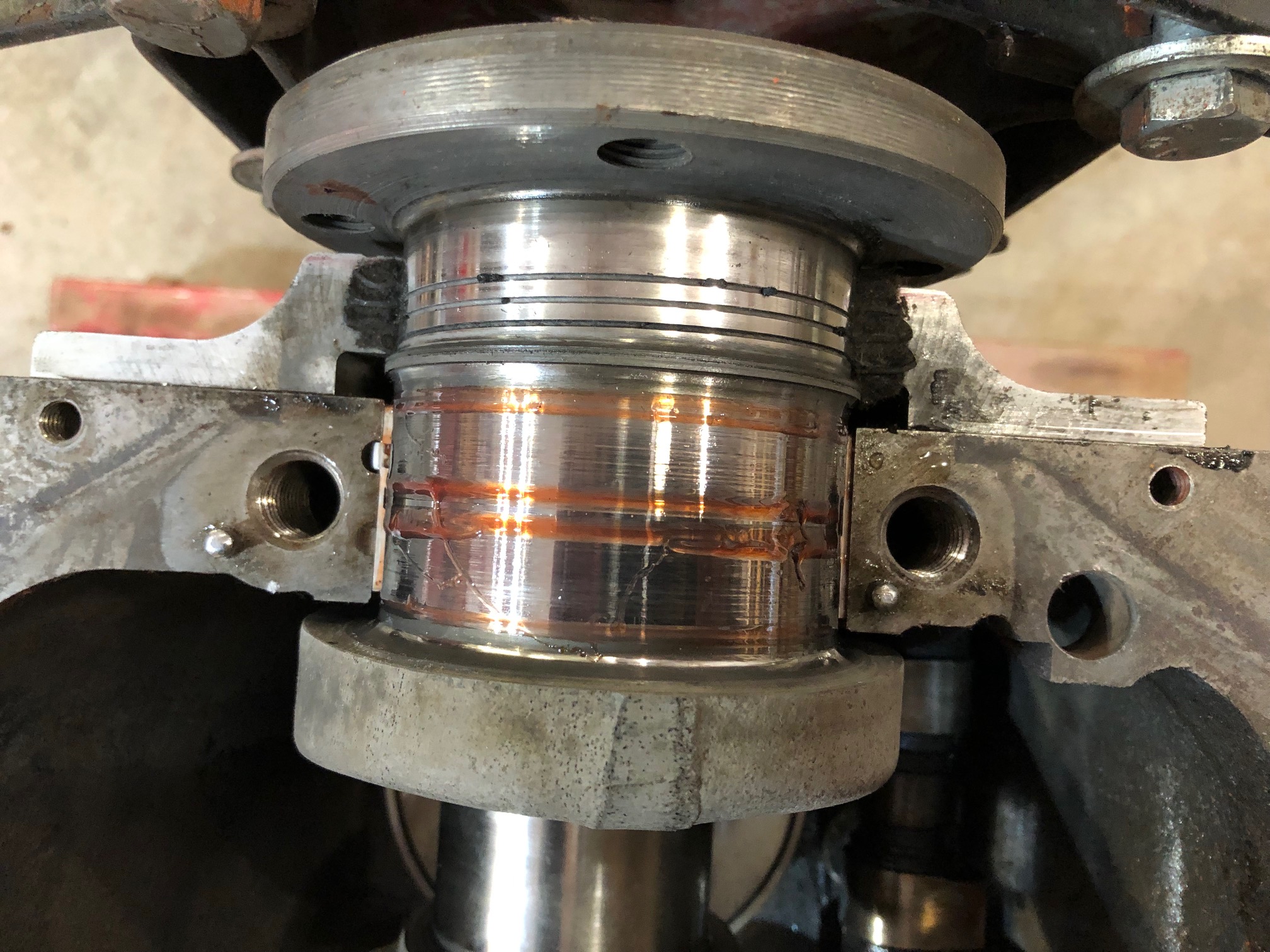

First time rebuilding one of these motors and the rear main seal installation has me at wits end. Part of the problem is I don't know what it should look like after seal is installed in bearing cap or upper seal holder. Whom ever built this motor last, used the WD seals that are way too short and narrow, no surprise there was a major leak!

Pictures show seal installed in groove after tightening down main caps. Wanted to see what happened to the excess material sticking up and where it was flowing over the sides.

I clamped the wet seals in the angle irons and put in the freezer overnight and then installed in grooves. That tip works to at least get the seal entirely in the groove.

Looking for thoughts on whether these look right and won't leak or do I need to start over.

|

|

Gary

Quincy, IL

D17 Series IV

|

|

|

Sponsored Links

|

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3713

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jan 2022 at 5:52pm Posted: 20 Jan 2022 at 5:52pm |

|

"F" gaskets missing?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jan 2022 at 7:28pm Posted: 20 Jan 2022 at 7:28pm |

|

They MUST be glued into place !!!!!!! I never use "F" gaskets. Just oil resist RTV where the F gaskets go and some of the 3M8001 glue on the ends of the seals to seal them up. Use 3M8001 to glue into the seals grooves. Wipe a thin layer on grease on the part that touches the crankshaft for lube. Seal ends have to extend past the ends to crush into place. I like to glue the seals in place and give them some set-up time and then final assembly on the engine.

|

|

Gary.IL

Bronze Level

Joined: 11 Dec 2021

Location: Quincy, IL

Points: 13

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jan 2022 at 9:28pm Posted: 20 Jan 2022 at 9:28pm |

I left F gaskets out for trial assembly. Used weather strip adhesive under the seals. So I should put some of that adhesive on ends of seal before final assembly of main cap?

Other than, do they look Ok to install caps and torque down?

|

|

Gary

Quincy, IL

D17 Series IV

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jan 2022 at 9:31pm Posted: 20 Jan 2022 at 9:31pm |

|

You can do as you want. I always glue the ends of the seals to each other and grease the part of the seal that touches the crankshaft so it isn't dry upon start-up.

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2562

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 5:42am Posted: 21 Jan 2022 at 5:42am |

|

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2126

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 7:35am Posted: 21 Jan 2022 at 7:35am |

The old "rope" seals. I've installed a lot of them into older engines in years gone by but never an "Allis-Chalmers" product. Your seal install doesn't look too bad to me from the camera angles and if it's in the block casting groove fully seated, the excess should be trimmed flush with the block deck with a sharp knife flat. This only if the main cap has a bit of rope seal protrusion past it's mating surface to the block. You need these two halves to slightly compress against one another when the main cap is installed, but not enough to "squish" out and possible compromise your mating surface of the parts.

I agree with others in that a very slender bead of adhesive should be spread onto the sealing surface of the block if the crankshaft is out. Same thing on the main cap. Also agree with a smear of grease on the surface of the seal so it's not dry upon engine start. A little dab of sealer on the ends of the rope seal is not a bad idea either but don't go overboard. I've always placed the rope seal in it's groove(s), then roll it in with a wood dowel rod but don't deform it. Doesn't take a lot of pressure but you want to ensure it's fully seated. Then smear the inner surface with a bit of lube and set the crank in the block. I don't know what "F" gaskets or seals are so no comment there.

Rope seals are very common in older engines and if installed correctly with modern sealers assisting, they are quite reliable. Just ensure you have a little compression action of the seal where the ends meet up when the rear main cap is torqued.

Seems like I did this on my Continental B-427 engine just last year.....

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 7:37am Posted: 21 Jan 2022 at 7:37am |

|

Cut off the ends of the protruding seals?? For sure it will leak.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 7:51am Posted: 21 Jan 2022 at 7:51am |

|

DON'T cut the ends of the seals off. They were made that long for a reason. Also glue them in. MACK

|

|

Gary.IL

Bronze Level

Joined: 11 Dec 2021

Location: Quincy, IL

Points: 13

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 11:09am Posted: 21 Jan 2022 at 11:09am |

Thanks.

Put it together per all the suggestions.

Done a lot of rear mains before but not one in a tractor or configured quite like this and it had the wrong seal in it when taken apart so I didn't have a comparison.

|

|

Gary

Quincy, IL

D17 Series IV

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2126

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 11:28am Posted: 21 Jan 2022 at 11:28am |

Good on you.

I had nothing to go from either as I've never touched an Allis engine in my life; only relaying my experiences with other antique engines. You had no replies at the time of my response so I jumped in.

Glad you got it sorted.

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1717

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2022 at 6:28pm Posted: 21 Jan 2022 at 6:28pm |

I agree with most everyone to glue the seal halves in the groove. The bottom of the aluminum retainer should be flush with the bottom of the block. You should also not cut the ends of the felt seal halves. Use the F gaskets and coat each side of the gaskets with a THIN layer of rtv/oil resistant silicone gasket maker. That is where my agreement ends.

It appears from the pics you are using aftermarket felt seal halves. I started to use those till I got fed up with how they don't fit properly. The aftermarket seal halves are too wide and slightly too think. When installed there is too much end sticking out of the groove. If you have 1/8" sticking out at each of the 4 ends, it will fold over instead of compress to be flat, I don't care how much you tighten. Too much seal end protrusion prevents the main bearing cap from making a tight seal against the top aluminum seal retainer resulting in oil leaking out the side gap where the F gaskets go. The ends of the felt seal should protrude about 1/16". Enough to compress to seal but not too much that the main cap can't tighten against the block and top retainer. The OEM felt seals are engineered for a PRECISE fit. I always use the OEM felt seal halves when doing rear main seals. They are so easy to install, within 1 minute I can take them out of the package and have 1 seal half properly in the groove. No clamping, no freezing, no waiting. See the 1st pic below for OEM seal in top retainer. 2nd pic shows the difference between the OEM seal half on the left and aftermarket seal half on right. The OEM seal is excellence in engineering and is what I would recommend you use.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

Gary.IL

Bronze Level

Joined: 11 Dec 2021

Location: Quincy, IL

Points: 13

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2022 at 6:37pm Posted: 22 Jan 2022 at 6:37pm |

Alex, That was exactly the info I was hoping to get. Guess I didn’t ask the right question! I was debating on getting OEM seals, because I didn’t feel the ones in the overhaul set fit right. I’m going to take it back apart and replace them. Lot less work now than after the tractor is all assembled.

|

|

Gary

Quincy, IL

D17 Series IV

|

|

RockhoundRanch

Bronze Level

Joined: 29 Mar 2017

Location: Kansas

Points: 1

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Mar 2022 at 3:05pm Posted: 08 Mar 2022 at 3:05pm |

|

Can someone post a picture of the F gaskets and where to get them?

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2562

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2022 at 5:45am Posted: 09 Mar 2022 at 5:45am |

|

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 790

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2022 at 11:51am Posted: 09 Mar 2022 at 11:51am |

|

Agco part # 70229178 need two

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1717

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2022 at 12:14pm Posted: 09 Mar 2022 at 12:14pm |

We have the D17/170/175 gas F gaskets in stock, part #229178, $1 per gasket, need 2 for the rear main seal.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)