| Author |

Topic Search Topic Search  Topic Options Topic Options

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1167

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Any tips or tricks for using a pull behind disk? Topic: Any tips or tricks for using a pull behind disk?

Posted: 22 Apr 2019 at 9:43pm |

So I have an 8' or so hydraulic disk (John Deere KBA maybe?), and I put it on the tractor tonight to go out and play around where I did some plowing last fall.

The earth was cutting good, but dang if this thing doesn't leave some

high and low ridges and just... Not want to track that straight.

Do I just have a worn out disk, or is this a common problem? Also, should I be taking half cuts, full cuts, double cuts... Cross cuts... What's the trick to getting the most out of discing.

|

|

|

Sponsored Links

|

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2019 at 9:49pm Posted: 22 Apr 2019 at 9:49pm |

|

That is the way disks work leaving ridges and grooves. Back when I did full tillage in the spring, I plowed one pass then ran the disk at an angle to the plow paths three times, then ran the field cultivator three passes to chop off the weeds and grass that survived the disk. I cut those passes to two and had a much smoother surface by adding a single row of spike tooth harrows behind the disk and behind the field cultivator the full width of each. I don't have pictures of them at the farm is now over 20 miles away from home. I haven't plowed in at least 20 years, and my tenant is a strip tiller.

Gerald J.

|

|

Michael V (NM)

Orange Level Access

Joined: 12 Sep 2009

Location: NM

Points: 2530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2019 at 9:54pm Posted: 22 Apr 2019 at 9:54pm |

|

I got rid of discs here for that reason,,leaving humps and ridges,,more ya change the angles, then ya really get ocean waves,, I guess there are some that level good,, but I haven't owned one...

|

|

Ky.Allis

Orange Level

Joined: 31 Jan 2010

Location: Kentucky

Points: 1036

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2019 at 10:41pm Posted: 22 Apr 2019 at 10:41pm |

|

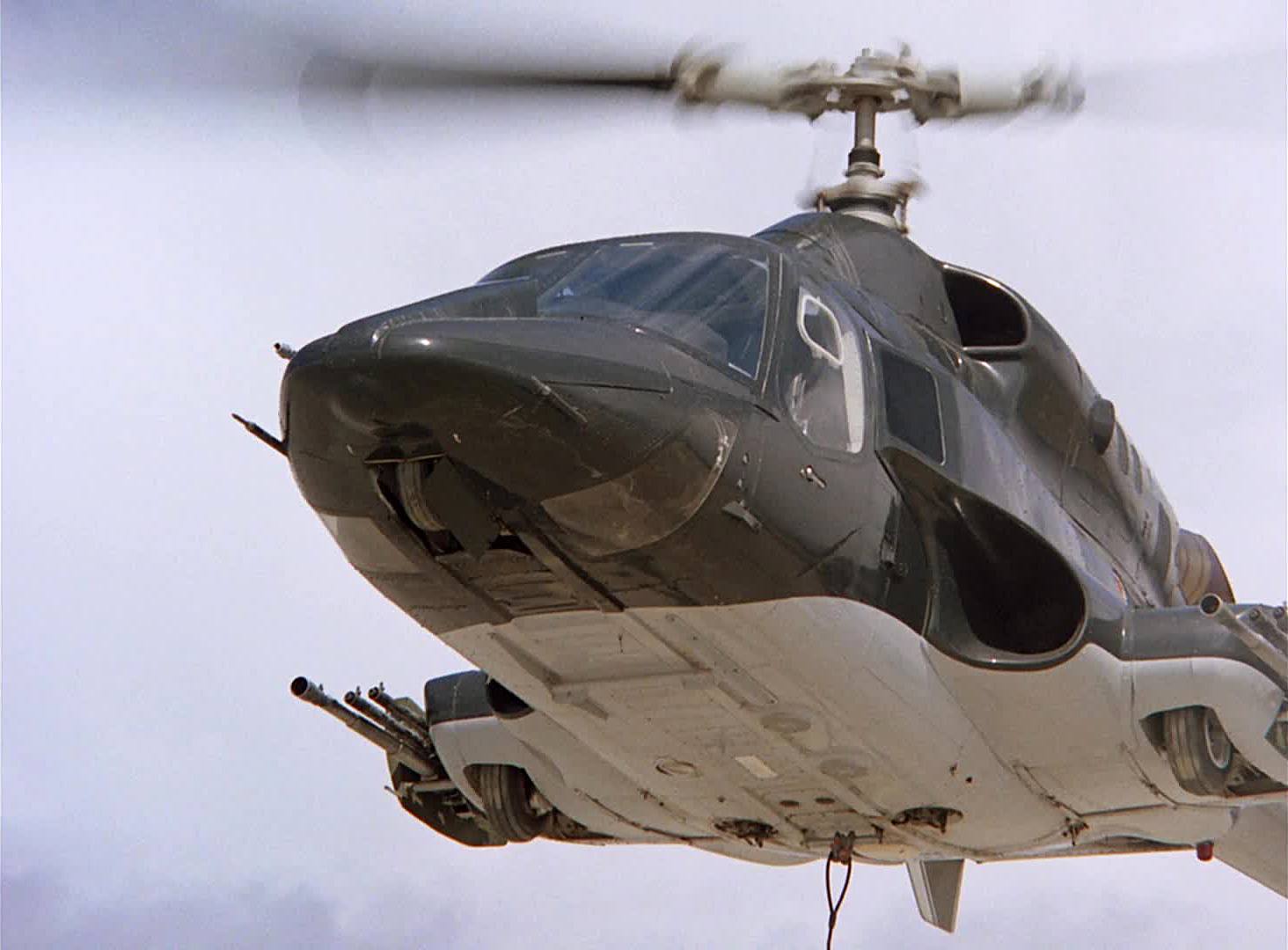

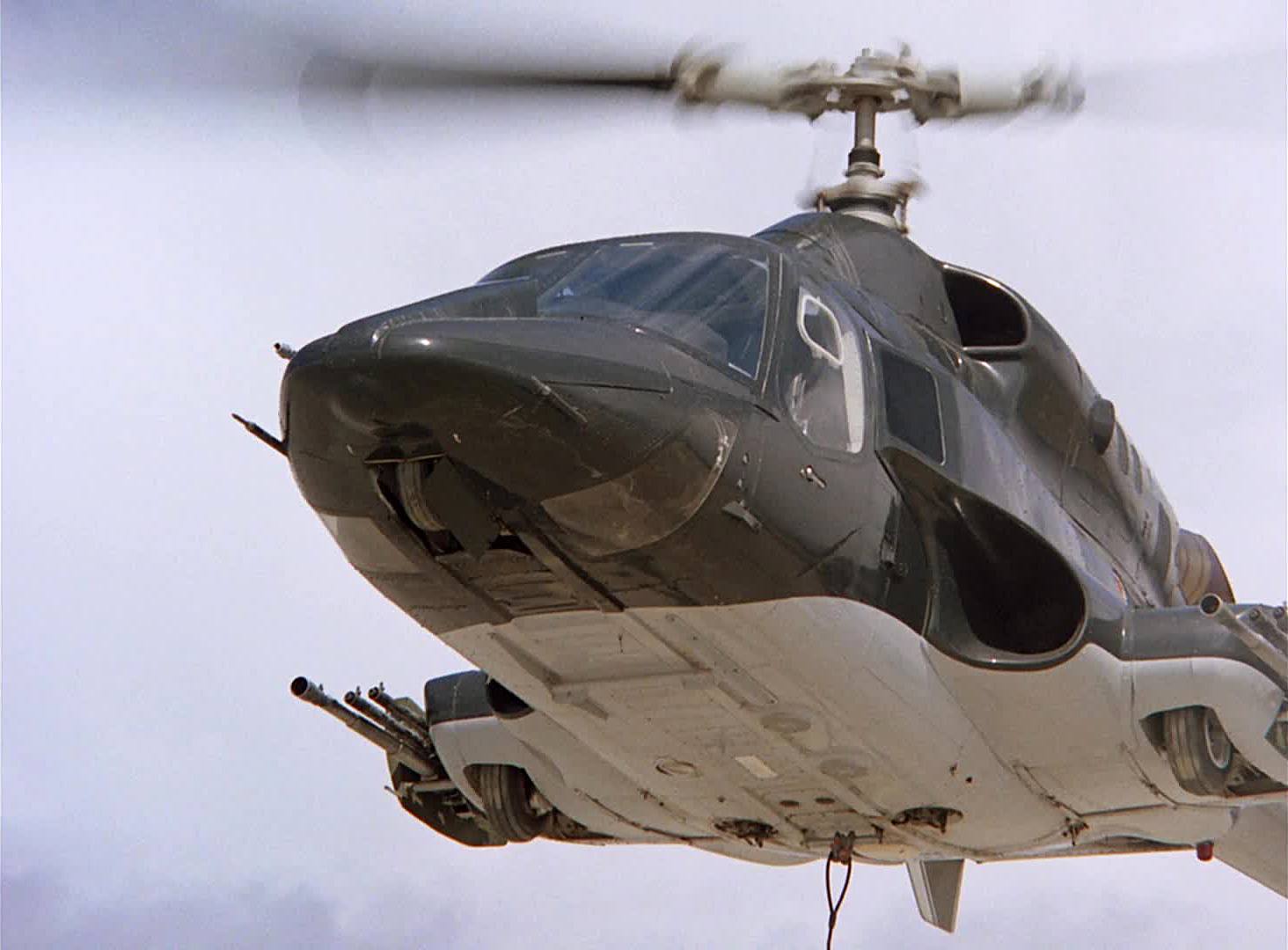

It's not a "KBA" disc. Maybe a "AW" model. A KBA disc is flexible and that one has a rigid frame and that is some of the problem.

|

|

HD6GTOM

Orange Level

Joined: 30 Nov 2009

Location: MADISON CO IA

Points: 6627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 12:32am Posted: 23 Apr 2019 at 12:32am |

|

How fast are you traveling. FAster you go the taller the ridges. You are gonna have to get yourself a harrow to smooth everything out. You might have to harrow it 3 of 4 different ways to smooth her out.

|

|

shameless dude

Orange Level

Joined: 10 Apr 2017

Location: east NE

Points: 13607

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 3:04am Posted: 23 Apr 2019 at 3:04am |

|

appears you have different size blades on it, fronts are worn down and the backs are bigger. experiment with changing the angle of the front gangs. also...as Tom says...slow down! nuthin over 4-5 MPH. most all the green disks from that era did a lot a ridging. most still do now-a-days, the big green farmers that do our ground bought a brand new big green disk this spring, our fields look like ocean waves. if you can find one, get a red disk, they do a much better job.

|

|

shameless dude

Orange Level

Joined: 10 Apr 2017

Location: east NE

Points: 13607

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 3:08am Posted: 23 Apr 2019 at 3:08am |

|

also...look on the right rear of your pic. it's packing in..in between the disks. get the scraper fixed, keep it clean between the disks. if you can find a good scraper, loop a chain around the spool and up over the frame, leave it loose, it will keep it clean between the blades.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54895

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 4:50am Posted: 23 Apr 2019 at 4:50am |

Front gangs are wore out. Disc also needs to be level front to back. You can adjust hitch height, I believe. also as others have said, keep the speed down. as for the scraper problem, a loop of barbed wire can do the same as chain, if you wanna keep the costs down. KBA's are notorious for being POS's, I'd trade for a better one, with adjusting cranks, to adjust the bite of the gangs, and the hitch height...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 5:27am Posted: 23 Apr 2019 at 5:27am |

|

You have a great AC tractor. It’s also good to see spring tillage photos - thanks for sharing. I have an older worn 12’ Kewanee Disk that ridges badly too. I’d double back on passes to try to get more even cut & manage ridges.

When my brother & I were young (10-12yrs old), we’d plant winter wheat in the fall. It took both of us to bucket the wheat from the Yetter gravity wagon’s 55 gal half barrel bolted under its door, to the drill. I drove the Farmall H & wagon. He drove the D17, disk, & drill. Dad had a one pass setup consisting of AC D17, AC 10’ disk, & JD 10’ grain drill. The AC disk did a fair job. It had 1/2 size outer blades on rear gang to help smooth out front gangs outer throw ridges. Yes, slower speed was critical.

Edited by AC7060IL - 23 Apr 2019 at 5:30am

|

|

Brian S(NY)

Orange Level

Joined: 13 Sep 2009

Location: CherryValley,NY

Points: 3383

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 5:27am Posted: 23 Apr 2019 at 5:27am |

I like to hook the harrow/drags behind the disks, will require less passes then unhook the disks and harrow at an angle across the field, if you havde rocks dont run the harrow to deep ;)

|

|

God made man.Sam colt made man equal.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 5:43am Posted: 23 Apr 2019 at 5:43am |

|

along with all the other comments, maybe too aggressive an angle ? I had a Flurry-bessel(sp) drag disc and used less angle, with a lot of weight in the back. I also did a E-W pass, then N-S pass, then final E-W pass with 'levelling ' chains to smooth it out .

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3157

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 6:07am Posted: 23 Apr 2019 at 6:07am |

|

You have what we used to call a transport disk.The pull behinds or drag disks were the ones with no rubber or carrier wheels if you can find an Allis Chalmers of that style it'll do a great job.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 6:28am Posted: 23 Apr 2019 at 6:28am |

Last tool before planting for me which was done here with horses before tractors also. Called a spring tooth. When the power and traction was available it was hooked behind the disc. Many times when conditions called for it the cultipacker was hooked behind the disc and then the spring youth was hooked behind the cultipacker. Always finish up corner ways so you can see the plater marker or drill tracks. Your disking job looks good very good.

Edited by Dick L - 23 Apr 2019 at 6:31am

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1167

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 7:21am Posted: 23 Apr 2019 at 7:21am |

Thanks for all the information, guys! Hot dang, I never realized there was so much to discing.

So, it does seem like my front gangs are smaller than the back, and I for sure have never even tried to level it (didn't realize that was what the front springy thing was for). Not only that, but I do have a drag that is the same size as the disc I could use, and I also have some harrow sections I could put behind it too. A couple of the discs have some pretty heavy damage on it (done before it was given to me -- but the price was right!).

And good call on that one section plugging up. I kept having that one back rear spot plug up on me.

I was running in second gear wide open throttle, and it was a bit rough going. I have no problems slowing down so I don't get bucked so dang hard in the seat! Also making secondary passes at off angles or 90 degrees to the original cuts would work fine for me too.

Thanks for all the pointers and info, everyone!

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 7:44am Posted: 23 Apr 2019 at 7:44am |

|

It is not the condition of the disc when you get ready to plant it is the condition of the soil. Money is more available for repairs to equipment than it was 70 years ago and good crops were grown with equipment in worse condition than your disc.

With the disc in my picture you set the angle to cut deeper. The deeper you cut the higher the ridges. With the wheel disc you lift the disc with the tires and your ridges will hot be as high. There is no rule that you have to disc with the disc set as deep as it will go. With fall plowing all you need is a seed bed. The ground is already mellow enough to get deep roots.

|

|

ACinSC

Orange Level

Joined: 16 Dec 2015

Location: South Carolina

Points: 3206

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 8:00am Posted: 23 Apr 2019 at 8:00am |

|

Years ago I remember my uncle that farmed dragging a board behind his big harrow . Still wonder how they didn't tear something up turning around. Didn't raise the harrow . Just spun around with the brake .

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 8:11am Posted: 23 Apr 2019 at 8:11am |

|

The 3rd pic, appears you have a ridge in the middle. That is caused by the back gangs digging deeper, or at more of an angle than the front. Even with larger blades in the back, you should be able to level the disc, so the front and back blades do the same amount of work, not leaving a ridge in the middle.

Pull a 2 section harrow behind that disc, running level, and you'll have a much smoother seed bed.

|

|

|

|

Tbone95

Orange Level Access

Joined: 31 Aug 2012

Location: Michigan

Points: 12357

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 8:12am Posted: 23 Apr 2019 at 8:12am |

|

I have a very similar disc, a 12 foot Deere RWA. It has moved a LOT of dirt for a lot of years and does a good job cutting up plow furrows for sure. Most of your field looks good, there are a few extra deep ruts and ridges, but looks reasonably consistent. Where you get plugged will cause unevenness, as will out of level as mentioned, but you'll never have a baby's butt finish. Like Dick said, no rule says you have to drop it deep all the time. In fact, your bearing carriers will thank you over time. I run deep on the first cut, and once it's worked up some like you have, I lower it enough to cover the wheel tracks and smooth things out. Still won't beat a spring tooth drag, spike harrow, rolling basket.....

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8641

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 8:17am Posted: 23 Apr 2019 at 8:17am |

Garden_guy, Nice pictures! Makes me want to get out and roll over some dirt too. Is thai the tractor that you did the front end work? I think your doing ok with the discs as is. Not sure how many times you have gone over the ground also? We sometimes disc three times on our tough hard clay packed soils prior to planting. Also going across at angles on tough ground. Yes we also used a spike tooth harrow and a plank lump smasher behind the dics to level the ground. Thanks for posting these! You have some good ground! What do you plan on planting there? Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Bob J Wi

Orange Level

Joined: 25 Mar 2011

Location: Wisconsin

Points: 270

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 9:35am Posted: 23 Apr 2019 at 9:35am |

See post on spring plowing. It shows how we set-up the disc and harrow for the 200. Works great and smooth enough for corn or beans.

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 10:37am Posted: 23 Apr 2019 at 10:37am |

|

Years ago an old timer neighbor told me that disking at 9 or 10 mph was more effective at killing weeds by the spinning disks tossing weeds and their roots up in the air where they would die from lack of soil.

Gerald J.

|

|

Tbone95

Orange Level Access

Joined: 31 Aug 2012

Location: Michigan

Points: 12357

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 10:55am Posted: 23 Apr 2019 at 10:55am |

Gerald J. wrote: Gerald J. wrote:

Years ago an old timer neighbor told me that disking at 9 or 10 mph was more effective at killing weeds by the spinning disks tossing weeds and their roots up in the air where they would die from lack of soil.

Gerald J.

|

Yeah, and if your back, disc, tractor, can take that ride, go for it. Then go back and smooth out the ridges!

|

|

bradley6874

Orange Level

Joined: 05 Sep 2010

Location: salisbury md

Points: 1349

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 12:56pm Posted: 23 Apr 2019 at 12:56pm |

|

Remember John Deere's only go putt putt so slow down and lighter the disc they couldn't pull it that deep😁😁😁🤡🤡🤡

Edited by bradley6874 - 23 Apr 2019 at 12:58pm

|

|

You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 2:54pm Posted: 23 Apr 2019 at 2:54pm |

Tbone95 wrote: Tbone95 wrote:

Gerald J. wrote: Gerald J. wrote:

Years ago an old timer neighbor told me that disking at 9 or 10 mph was more effective at killing weeds by the spinning disks tossing weeds and their roots up in the air where they would die from lack of soil.

Gerald J.

|

Yeah, and if your back, disc, tractor, can take that ride, go for it. Then go back and smooth out the ridges! |

I'm an old timer and when I was at home if I would have tried pulling a disc that fast I would be a funny looking old timer. Dad would have kicked my behind so hard I would still have my neck attached directly to my hips.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 3:45pm Posted: 23 Apr 2019 at 3:45pm |

|

May I ask you at what stage do you apply fertilizer?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 3:55pm Posted: 23 Apr 2019 at 3:55pm |

|

Depends on what your planting or what your using to plant with. Most corn beans or oats this time of year is put on while planting with the same planter or drill. On corn nitrogen is side dressed later. Some fertilizer is applied before plowing or now days tilling with one of many types of field cultivators.

|

|

BradH

Orange Level

Joined: 28 Feb 2016

Location: Corydon Ia.

Points: 264

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 6:31pm Posted: 23 Apr 2019 at 6:31pm |

We were just doing some of this over the weekend. My father-in-law is a big advocate for pulling the spike harrow sections behind the disc. It also helps break the clods more with one pass. This maens fewer passes across the field and less soil compaction. When my dad quit row cropping he converted some of the ground to hay field. While he was at work he had somebody run the disc across it one last time. The problem was that the disc was adjusted wrong so it threw ridges out to the sides with each pass. That hay ground had ridges in it for the next 20 years until he and my brother started farming again. You could tell every time you rode east to west across the field. You could feel a ridge every 14 feet or so. Later, Brad

|

|

Warning! Blind man with a tractor! Head for the hills!

|

|

Jim Hancock

Orange Level

Joined: 11 Sep 2009

Location: EL Reno, Ok.

Points: 1112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 7:32pm Posted: 23 Apr 2019 at 7:32pm |

Hi Garden Guy. Like the others, your ground looks good. May I suggest what we did about the furrows made from the back gang ends? We clamped a slightly smaller disc on the ends that pulls some dirt back into the furrow made with the bigger blade as it it doesn't sink and cut as deep as the bigger blade. For example, if your main gang blades are 18", put on a 16" on the ends. This helped us with furrow problems in addition to dragging a spike tooth harrow behind the disc. We had the harrow lying in the forward position when pulled and not standing straight up.

|

|

How blessed we are by HIS GRACE!

|

|

wheatbreeder

Orange Level

Joined: 12 Sep 2009

Location: Harrow, Ontario

Points: 581

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 7:37pm Posted: 23 Apr 2019 at 7:37pm |

you need to level it from to front to back it's pulling more soil back in than what the front is moving out

|

|

Farm stuff 8050,6690,175,F2,5050,WD

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2884

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2019 at 9:01pm Posted: 23 Apr 2019 at 9:01pm |

|

1) Slow down

2) Your disc needs new blades and bearings

3) Deere makes poor tillage equipment as Shameless said get a red disc preferably a Sunflower or Krause

4 It’s chopped up enough use a field cultivator.

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Gerald J. wrote:

Gerald J. wrote: