| Author |

Topic Search Topic Search  Topic Options Topic Options

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis d15 power director repair/adjustments Topic: Allis d15 power director repair/adjustments

Posted: 09 Mar 2025 at 4:56pm |

|

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22140

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2025 at 5:12pm Posted: 09 Mar 2025 at 5:12pm |

|

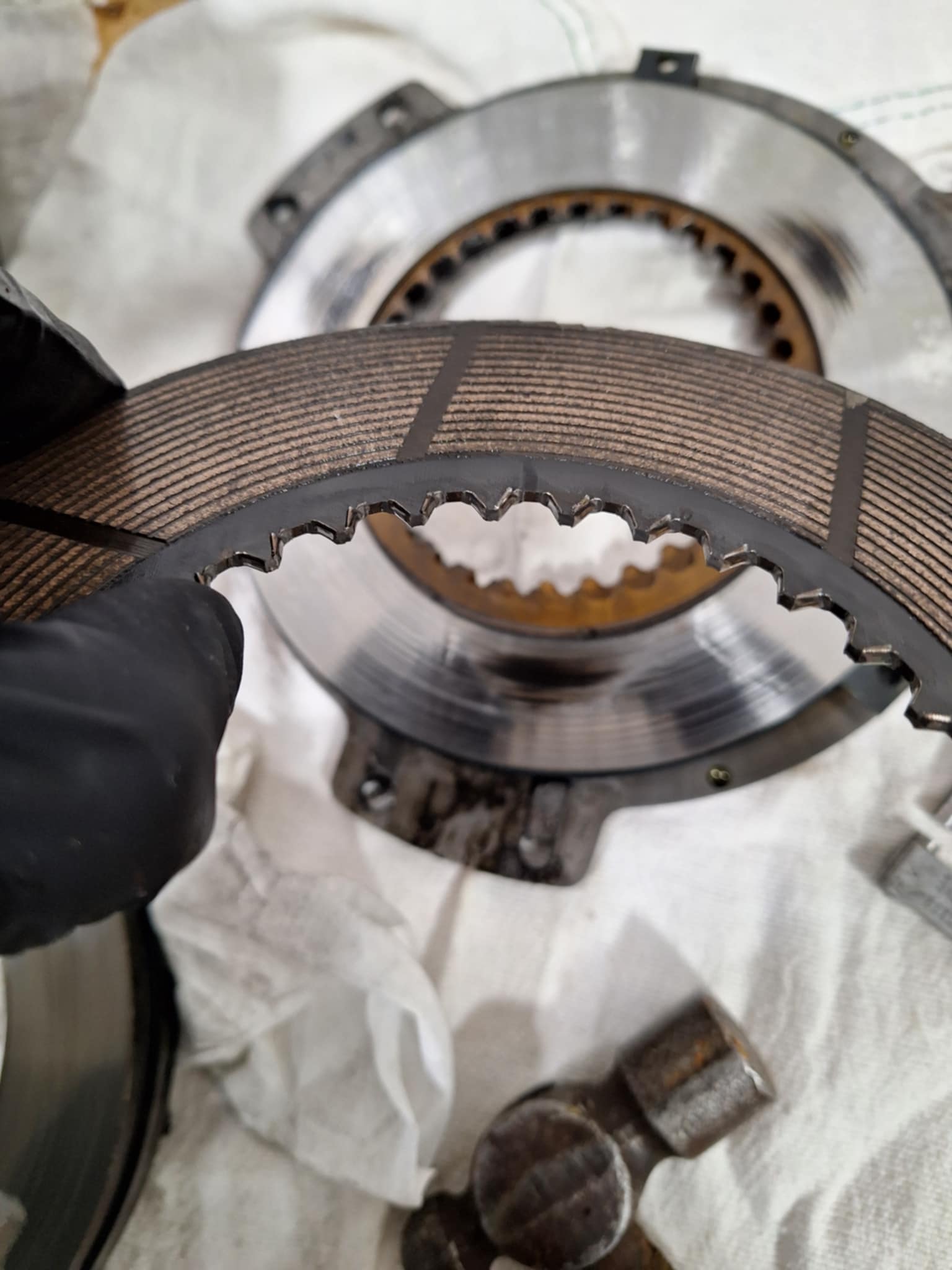

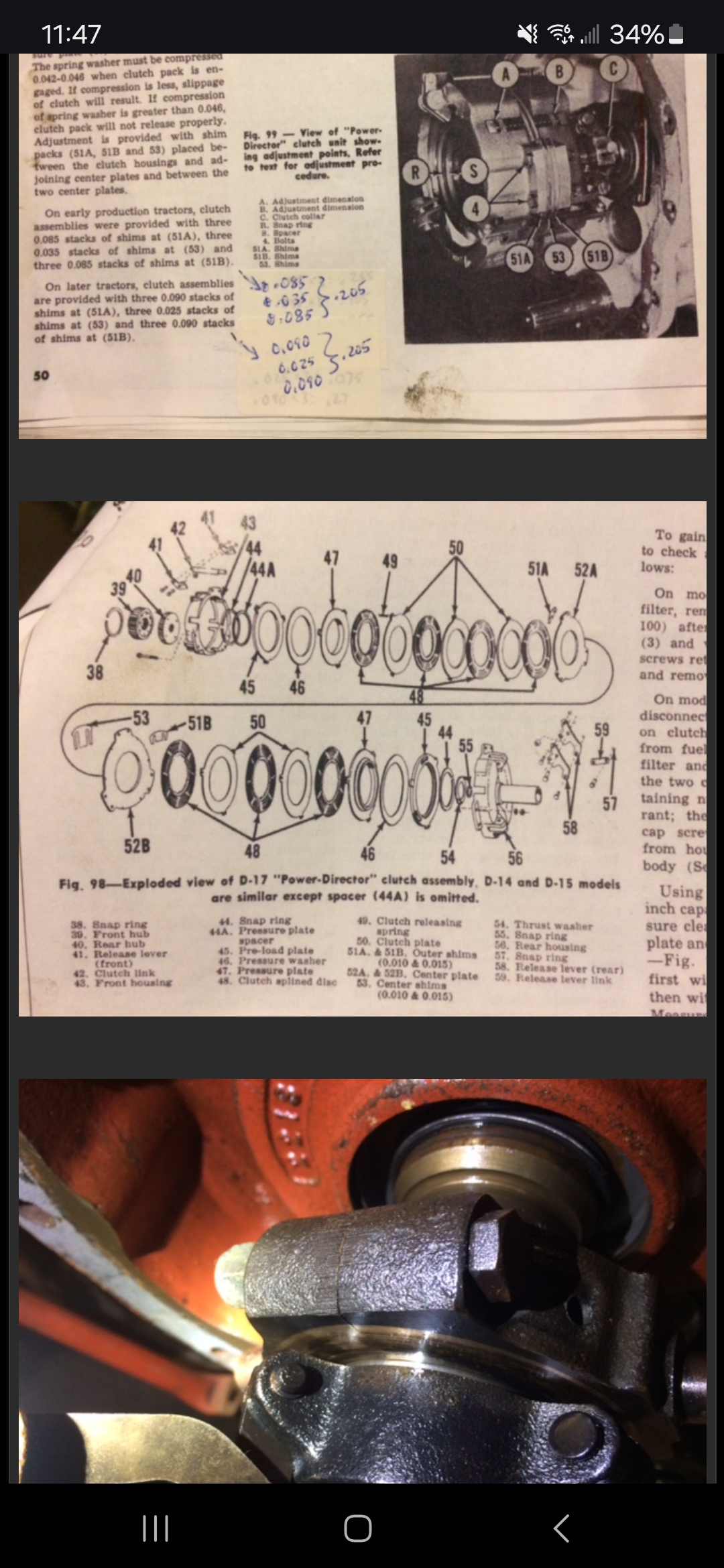

Some ignorant individual has been working on it !! The grand total of .205" MUST BE MAINTAINED !!! This insures full stroke on the hand lever and 100% release and 100% full engagement of both clutches. LONG shims only must be used in the center. SHORT shims only must be used in the other two locations. Your two ramp plates where the rollers operate are SHOT and this causes jump out. The two drive hubs where notches are carved into the hub teeth are junk. The driving discs teeth are badly worn. Personally, I have never seen a Power Director clutch in as terrible of shape as this one is. I wouldn't fix it. Find a good USED one and get on with life.

Edited by DrAllis - 09 Mar 2025 at 5:14pm

|

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2025 at 5:15pm Posted: 09 Mar 2025 at 5:15pm |

|

Thanks for the reply. I was kind of afraid of that. Looks like the last guy in there was just doing whatever it took to limp it along.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2425

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2025 at 9:54pm Posted: 09 Mar 2025 at 9:54pm |

|

I would agree with the overall condition of that clutch assembly. I would certainly hope that there are better ones available in salvage yards, or forum members.

|

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2025 at 11:44pm Posted: 09 Mar 2025 at 11:44pm |

|

It looks like a d17 powerdirector shares some of the same components with a d15. Looks like the clutch disc's are the same along with the preload plates. Would the shims and drive hubs interchange as well?

|

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2025 at 11:50pm Posted: 09 Mar 2025 at 11:50pm |

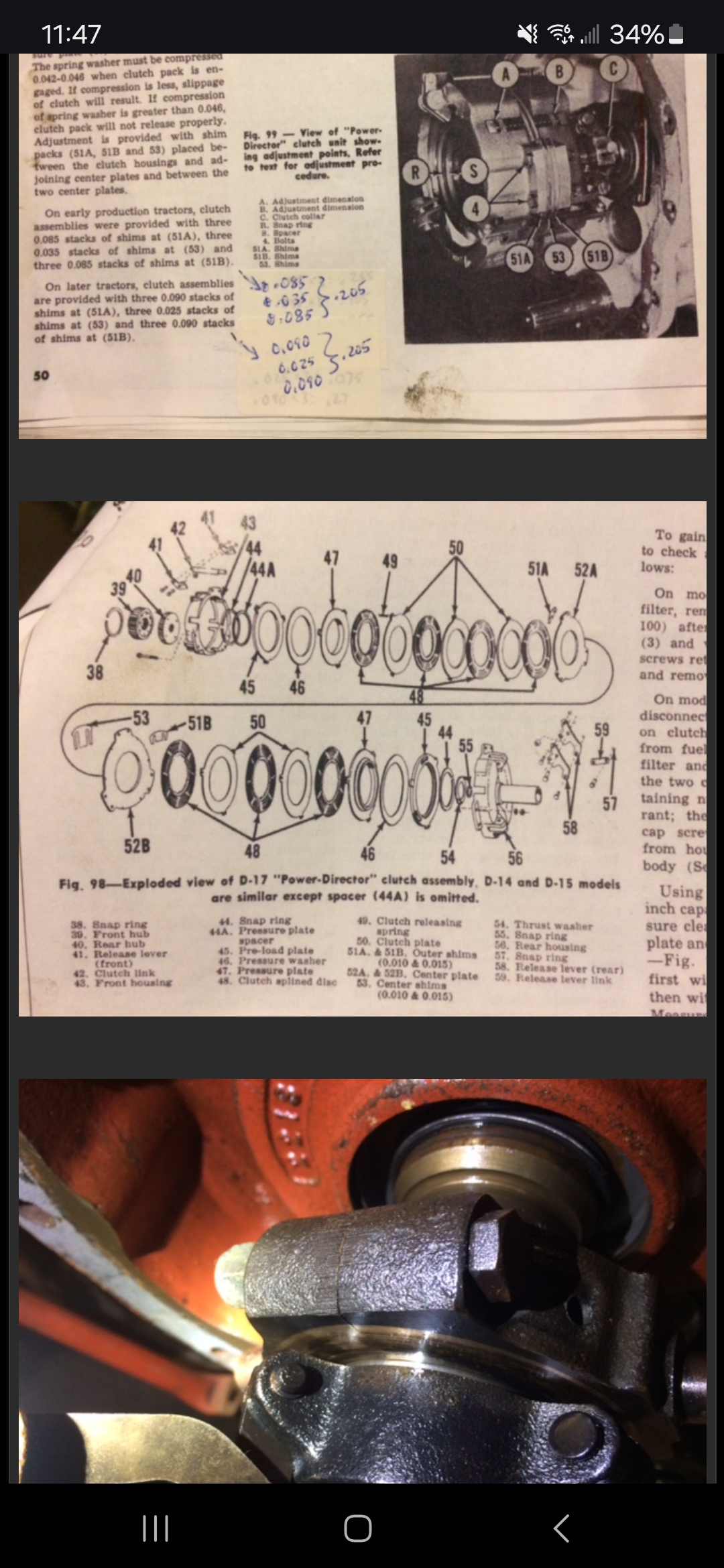

A screenshot of an older post on a d17 power director repair.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4132

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2025 at 6:22am Posted: 10 Mar 2025 at 6:22am |

|

There were 3 D-15 power directors on a hayrack at the auction I went to Saturday. Bad timing I guess. Didn't even watch them sell.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22140

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2025 at 6:26am Posted: 10 Mar 2025 at 6:26am |

|

Any D-17 PD clutch is 4 discs in low range (front) and 3 discs in high range (rear). So a good many of the parts are the same except when it comes to anything related to the front clutch section. So, the hub is wrong and any of the long linkage parts and small return springs and maybe the front housing itself. Discs and plates and shims all interchange. The ramp plates are normally the only parts that get replaced for jump out issues. Maybe the rollers too. D-14 and D-15 clutches are identical.

|

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2025 at 9:53am Posted: 10 Mar 2025 at 9:53am |

|

Are both ramp plates on the d17 clutch the same?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22140

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2025 at 9:55am Posted: 10 Mar 2025 at 9:55am |

|

Yes. What I call the ramp plate is the plate that the roller levers roll thru the pockets to engage the clutch.

|

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2025 at 4:14pm Posted: 10 Mar 2025 at 4:14pm |

|

So a d17 PD would also be a viable option for ramp plates and a rear drive hub. I'll have to see what I can round up.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8741

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2025 at 7:55pm Posted: 10 Mar 2025 at 7:55pm |

|

Get yourself parts books and compare part numbers

|

|

1950AllisWD

Bronze Level

Joined: 04 Jan 2025

Location: Iowa

Points: 28

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2025 at 11:26am Posted: 11 Mar 2025 at 11:26am |

|

Looks like the part number for the two ramp plates on the d15 clutch is 0230015.

The rear clutch hub is 022807.

Does anyone have a d17 parts Manual handy they could share a picture of? The reason I'm so interested in the d17 clutch is there is one on ebay for $100. The guy is going to send me some pictures of the rear drive hub and any wear present on the ramp plates tonight. ASAP tractor parts has ramp plates listed on there website as fitting the d14, d15, and d17. So if both ramp plates are the same in the 17 clutch then this clutch may be a good parts candidate.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8741

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2025 at 12:38pm Posted: 11 Mar 2025 at 12:38pm |

|

Agco parts website you can view them

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5052

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2025 at 8:22am Posted: 12 Mar 2025 at 8:22am |

|

Personally, I would be looking at AGCO parts. Mikez, Brenda (at Sandy Lake Equipment) or Alex (at A&W Tractor) should be able to source AGCO parts. They will also know what they (and you) are talking about if you need some advice when rebuilding the power director.

Edited by WF owner - 12 Mar 2025 at 8:24am

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1759

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2025 at 11:28pm Posted: 12 Mar 2025 at 11:28pm |

I too have never seen a power director with that much wear on it. It is salvageable, but you would spend more time and money to get that one back in proper operating condition vs purchasing a used one.

You should not start with a D17 power director. The end housings are different, the splined hubs are different, and the linkages are longer. The 230015 preload plates, brass shifter, clutch discs, shims, and separator plates are all the same.

That picture from the older post of the different specs for later tractors is from an IT manual. Toss those IT manuals in the garbage where they belong. Use only Allis service manuals.

Allis/AGCO parts are the way to go with these clutches, however the 230015 plate was discontinued last year from AGCO. If you need help with finding good parts, you can call the store and we'll be glad to help you!

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)