| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: AC 80 t wear plate position? Topic: AC 80 t wear plate position?

Posted: 07 Oct 2021 at 5:54pm |

|

Where exactly do the wear plates fit on the bar does anyone have any drawings of how these go together that are specific and clear or able to describe it? I bought five new wear plates but things seem a little out of position, thanks Matt

|

|

|

Sponsored Links

|

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10826

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 6:06pm Posted: 07 Oct 2021 at 6:06pm |

|

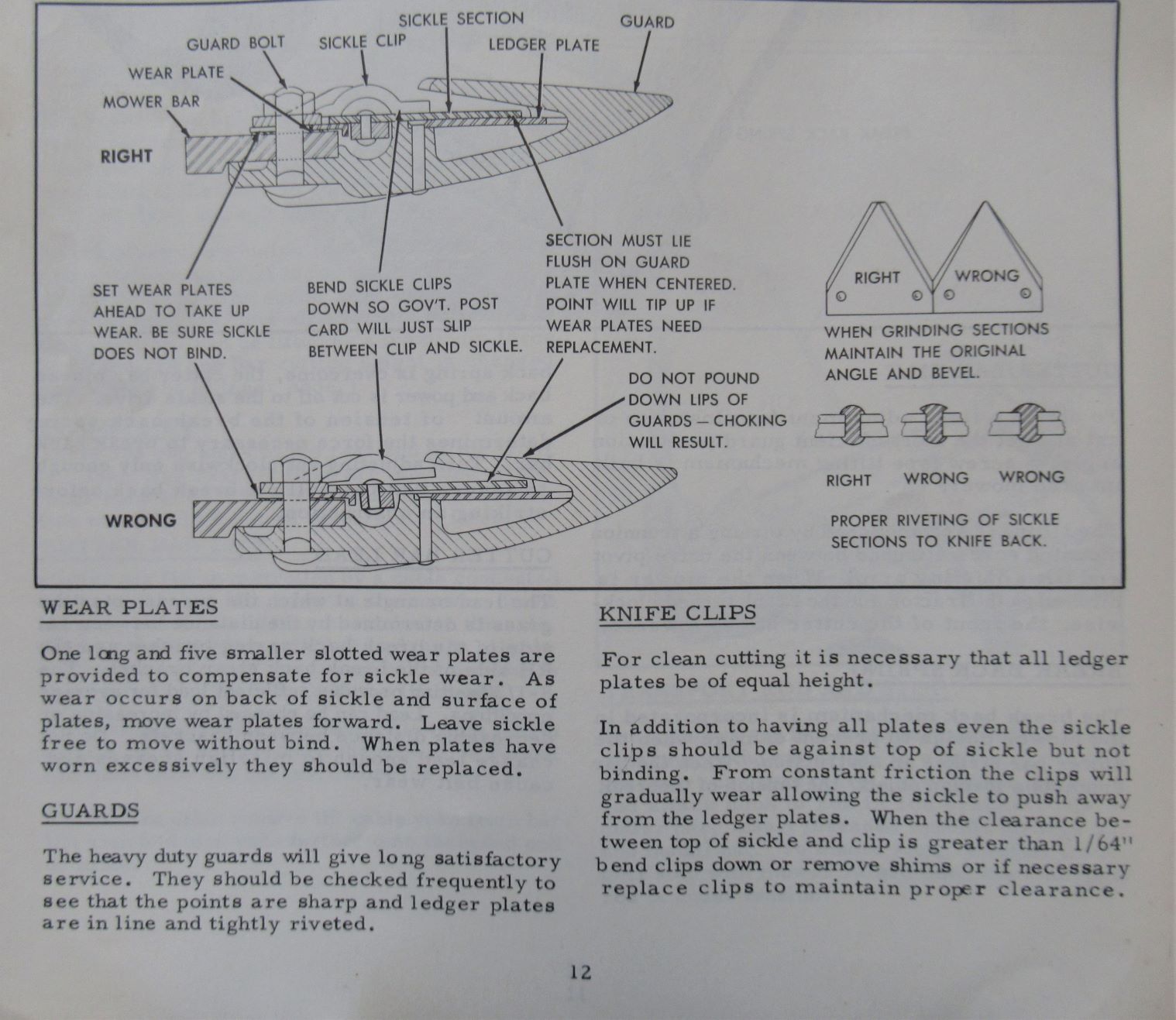

The wear plate will fit on the bar front edge. When the sickle it moving in and out, while cutting hay, the sickle blade pushes back against them to save wear on the bar itself. They are throw away wear parts. Should be captured by 2 bolts each. Some will be under the hold down clamps, but not all. HTH Tracy

|

|

No greater gift than healthy grandkids!

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 6:33pm Posted: 07 Oct 2021 at 6:33pm |

|

Okay some of the actual sickle was up on top of the wear plates in the entire 90° edge that I suppose they would ride on was pretty much gone. There's a very long looking wear plate up by the cutter head that the sickle is riding on top of? Is it possible that the sickle rides on top of the long wear plate by the sickle head and not on top of the other wear plates but out in front of them?

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 8:01pm Posted: 07 Oct 2021 at 8:01pm |

there’s a long wear plate 13 bolts I think 12 teeth then starts with short wear plate, two bolts, skip a bolt then another. Uses five shorts.

Edited by Mikez - 07 Oct 2021 at 8:09pm

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 8:08pm Posted: 07 Oct 2021 at 8:08pm |

|

Hope that makes sense. Quick sketch

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 8:42pm Posted: 07 Oct 2021 at 8:42pm |

|

Yes and thank you very much for taking the time to draw that because it's telling me that something is not set up right to begin with because my entire sickle bar is or was riding on top of all the wear plates. Edit, now that I'm looking at your picture again it does look like a small portion rides on top of the where plate and the other portion pushes up against the small bent piece. Thanks Matt

Edited by Hunt4Allis - 07 Oct 2021 at 8:44pm

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 8:49pm Posted: 07 Oct 2021 at 8:49pm |

|

If that drawing is correct the very back edge of the sickle blade rides on top of the wear plate?

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2021 at 11:09pm Posted: 07 Oct 2021 at 11:09pm |

|

what issue are you having.

|

|

orangereborn

Orange Level

Joined: 12 Sep 2009

Location: NW WI

Points: 1495

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 12:24am Posted: 08 Oct 2021 at 12:24am |

|

That is correct, sections on the sickle knife bar over hang to the rear of the bar and ride on top of the wear plates. The sickle knife bar rides against the front edge wear surface of the wear plate. And the arch clips are adjusted to hold the knife assy down in that position... They do overhang?? Mikes diagram would be accurate...Dale

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 12:29am Posted: 08 Oct 2021 at 12:29am |

|

don’t forget the washers under each clip “hold down”. If you forget them and tighten bolts it will pinch the blades

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 4:34am Posted: 08 Oct 2021 at 4:34am |

|

Does what overhang? I'm just rebuilding it and there are no washers on any of the bolts that I took off under the hold down clips?

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 6:36am Posted: 08 Oct 2021 at 6:36am |

|

Pinch blade? Doesn't the hold down clips contact each knife section to hold it down?

Wish I had a detailed picture of exactly how this should look when correct( with washers and everything)

Thanks Matt

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 7:31am Posted: 08 Oct 2021 at 7:31am |

|

Are you using original individual guards? I converted to New Holland style twin guards years ago. No need for wear plates. Only guards and hold downs.

|

|

Brian G. NY

Orange Level

Joined: 12 Sep 2009

Location: 12194

Points: 2269

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 7:45am Posted: 08 Oct 2021 at 7:45am |

JK in Pa wrote: JK in Pa wrote:

Are you using original individual guards? I converted to New Holland style twin guards years ago. No need for wear plates. Only guards and hold downs. |

Could you post a picture of that configuration? Can't seem to picture it in my mind.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 7:51am Posted: 08 Oct 2021 at 7:51am |

|

Yes original guards

Link to upgraded guards?

|

|

Brian G. NY

Orange Level

Joined: 12 Sep 2009

Location: 12194

Points: 2269

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 8:31am Posted: 08 Oct 2021 at 8:31am |

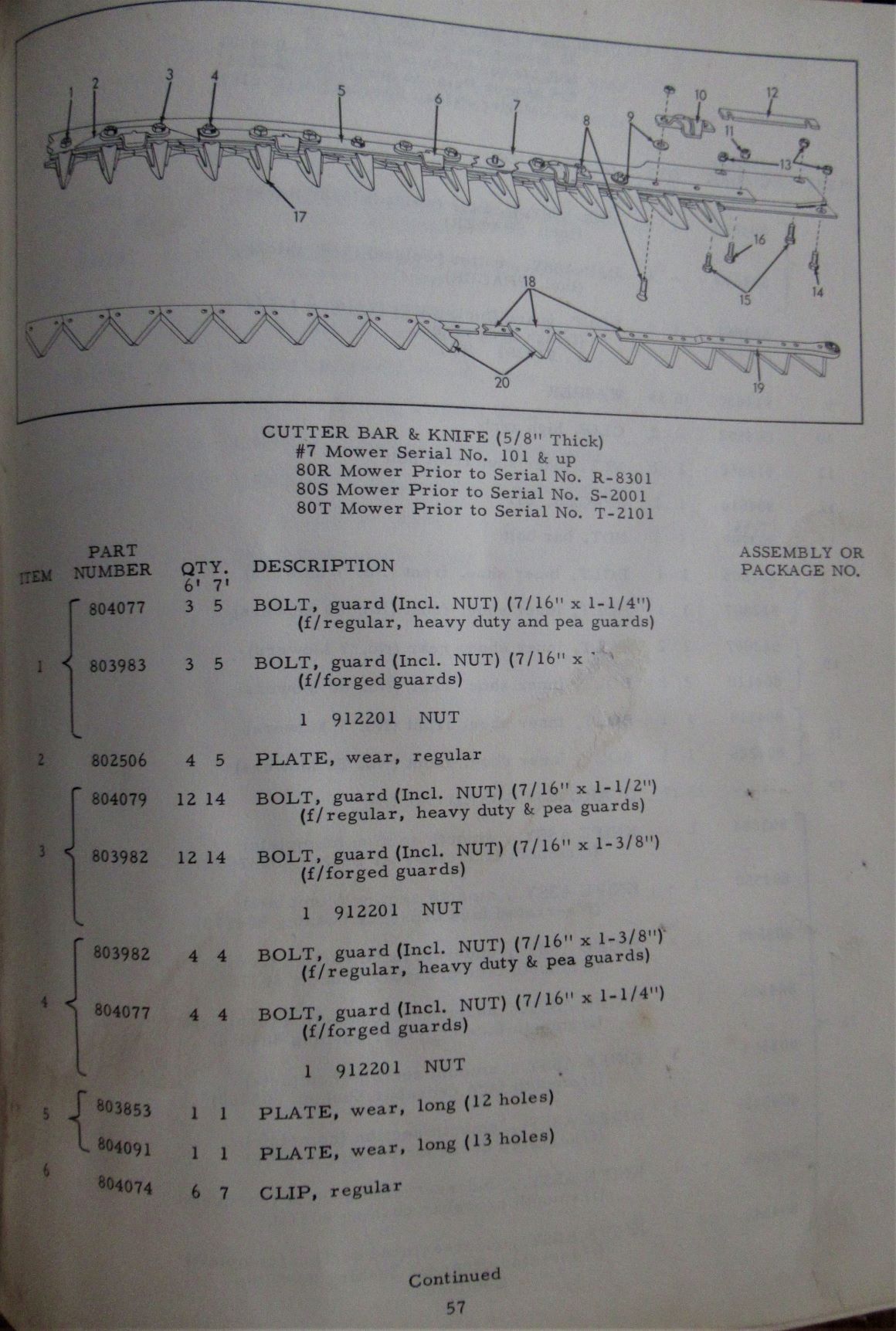

The original A-C wear plates were of different lengths. Here are diagrams and instructions on adjusting them.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 8:43am Posted: 08 Oct 2021 at 8:43am |

|

I don't see washers needed in between hold down clips and wear plate?

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 8:56am Posted: 08 Oct 2021 at 8:56am |

Operators manuals, Parts books and service manuals go to great lengths explaining things, however they can't understand things for some.

everyone should have all 3 manuals for all the equipment that they are working with.

Edited by PaulB - 08 Oct 2021 at 8:57am

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 8:58am Posted: 08 Oct 2021 at 8:58am |

|

Great thanks

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 9:01am Posted: 08 Oct 2021 at 9:01am |

Mikez wrote: Mikez wrote:

don’t forget the washers under each clip “hold down”. If you forget them and tighten bolts it will pinch the blades |

I guess I was referring to Mike's comment, hoping he would know...

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 9:08am Posted: 08 Oct 2021 at 9:08am |

|

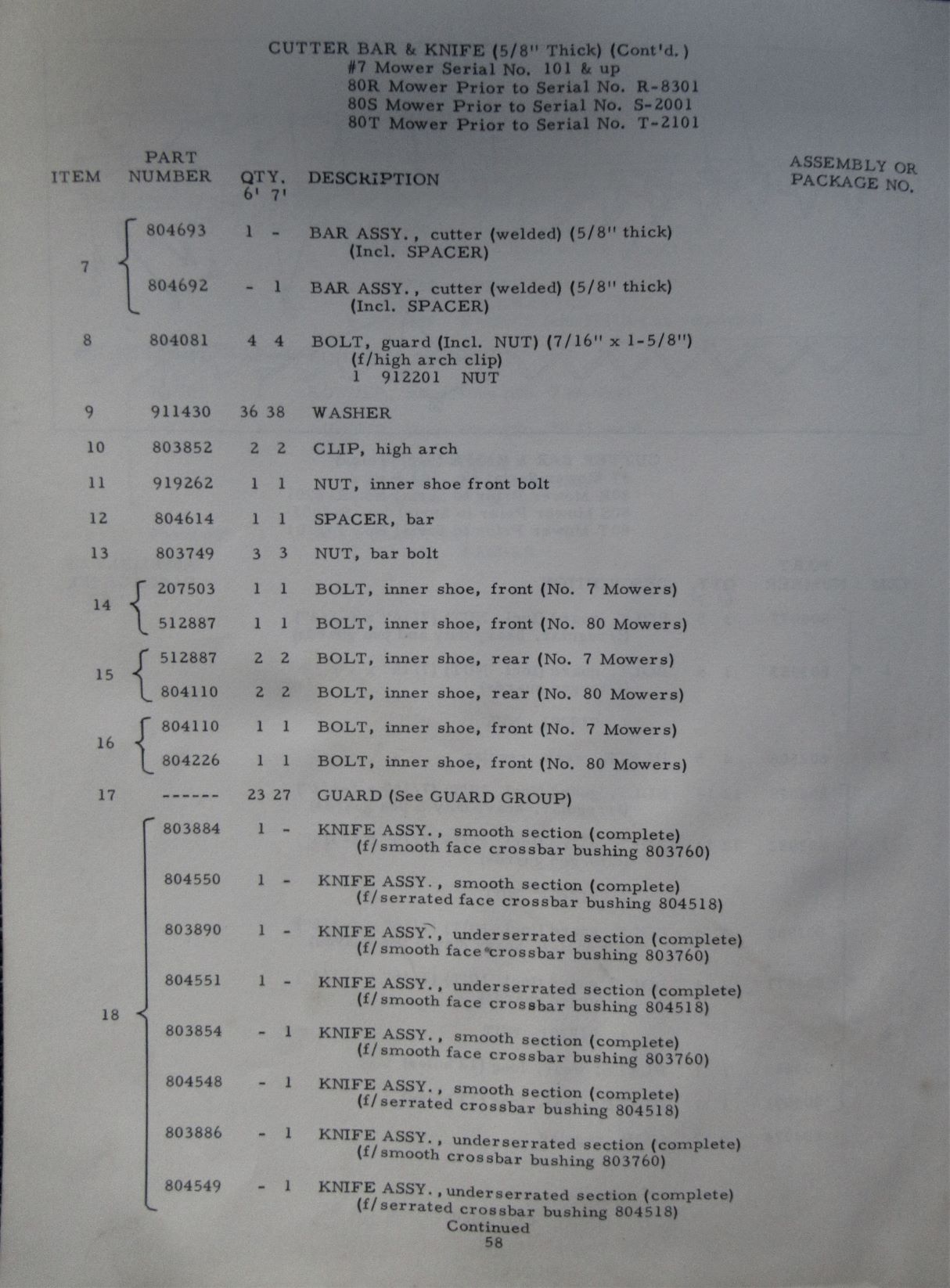

Brian post the next page where it shows #9 the washers. Qty 36 or 38 part number 920310 or old #911430

Edited by Mikez - 08 Oct 2021 at 9:09am

|

|

Brian G. NY

Orange Level

Joined: 12 Sep 2009

Location: 12194

Points: 2269

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 2:04pm Posted: 08 Oct 2021 at 2:04pm |

Here you go Matt. Page 58

|

|

Brian G. NY

Orange Level

Joined: 12 Sep 2009

Location: 12194

Points: 2269

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 2:09pm Posted: 08 Oct 2021 at 2:09pm |

|

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Oct 2021 at 8:41pm Posted: 08 Oct 2021 at 8:41pm |

|

Brian, the New Holland style guards have a ledge area that supports the back of the knife and keeps the knife level with the cutting area. Hope this helps explain how they work.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Oct 2021 at 7:15am Posted: 09 Oct 2021 at 7:15am |

|

Thanks everyone very much for the info, now I can get this thing back together the right way and get to cutting if we dry out!

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3097

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Oct 2021 at 7:55am Posted: 09 Oct 2021 at 7:55am |

JK in Pa wrote: JK in Pa wrote:

Brian, the New Holland style guards have a ledge area that supports the back of the knife and keeps the knife level with the cutting area. Hope this helps explain how they work. |

I 2nd the NH style guards and will make the mower cut better too.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Oct 2021 at 7:59am Posted: 09 Oct 2021 at 7:59am |

|

show us pictures please

|

|

JoeO(CMO)

Orange Level

Joined: 11 Sep 2009

Location: Cent Missouri

Points: 2696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Oct 2021 at 8:30am Posted: 09 Oct 2021 at 8:30am |

PaulB wrote: PaulB wrote:

Operators manuals, Parts books and service manuals go to great lengths explaining things, however they can't understand things for some.

everyone should have all 3 manuals for all the equipment that they are working with. |

X2

X3

X4

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Oct 2021 at 6:50pm Posted: 10 Oct 2021 at 6:50pm |

|

Thanks everybody for your info, got it back together had some difficulties with the breakaway feature on the 80 t tho...

I finally got it apart and was able to get the belt put back on the drive but I had to remove the tension bolt completely. I'm going to get a new bolt because this one looks pretty bad. I know the manual I have says it should break away once it contacts something but not under normal circumstances mowing. Does anyone know how far in the bolt should be tightened to make this happen? Thanks Matt

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2021 at 5:43am Posted: 11 Oct 2021 at 5:43am |

|

The joint that moves to let it break away was rusted solid. I'm thinking if I put the bolt in about halfway to start with and see how it goes? Can't hurt to ask if someone has one of these and just knows off the top of their head how tight they normally run it on an 80t?(

Edited by Hunt4Allis - 11 Oct 2021 at 5:44am

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

JK in Pa wrote:

JK in Pa wrote: